Non-drip spout closure

A technology of closures and components, applied in the field of non-droplet nozzle closures, which can solve the problems of consumers who are difficult to hold and open bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific terms are used hereinafter for convenience only and not for limitation. Unless otherwise indicated, any directional terms such as "upper," "lower," and "outer" are used to indicate a direction relative to the closure of the present invention when the closure is in an upright position. This term includes the above words as well as their derivatives and other words of similar import. Referring now to the drawings, like reference numerals designate like or corresponding parts throughout the several views.

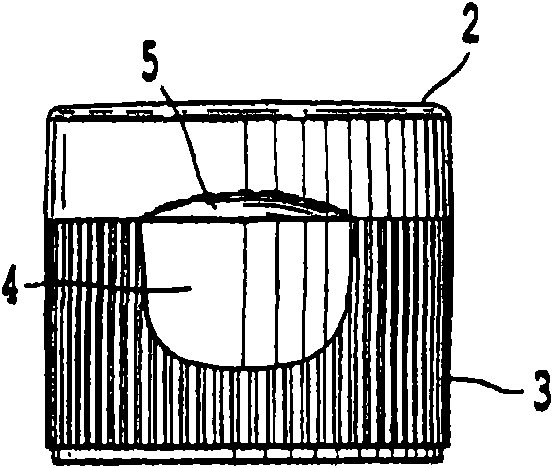

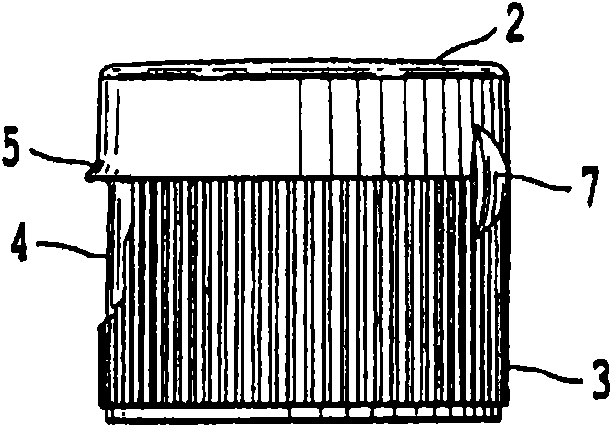

[0038] Such as Figure 1-7 As shown, a non-droplet nozzle in the form of a closure 1 comprising an inverted top 2 and a base 3 . In order to open the flip top 2 a tongue 5 is provided along one side of the flip top 2 adjacent to a planar groove 4 formed in the base 3 . The base 3 has a threaded portion for screwing onto the top of a bottle or container with mating threads. The base 3 has ribbed sides 6 for screwing or unscrewing the closure 1 to or from a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com