Motor rotor structure and manufacturing method thereof

A technology of motor stator and manufacturing method, which is applied in the field of structure and stator manufacturing, and can solve the problems of high cost, high price, and inferior performance to silicon steel sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technology, means and effects that the present invention takes to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention can be obtained from this in-depth and specific Understand, however, the provided drawings are only for reference and illustration, and are not intended to limit the present invention.

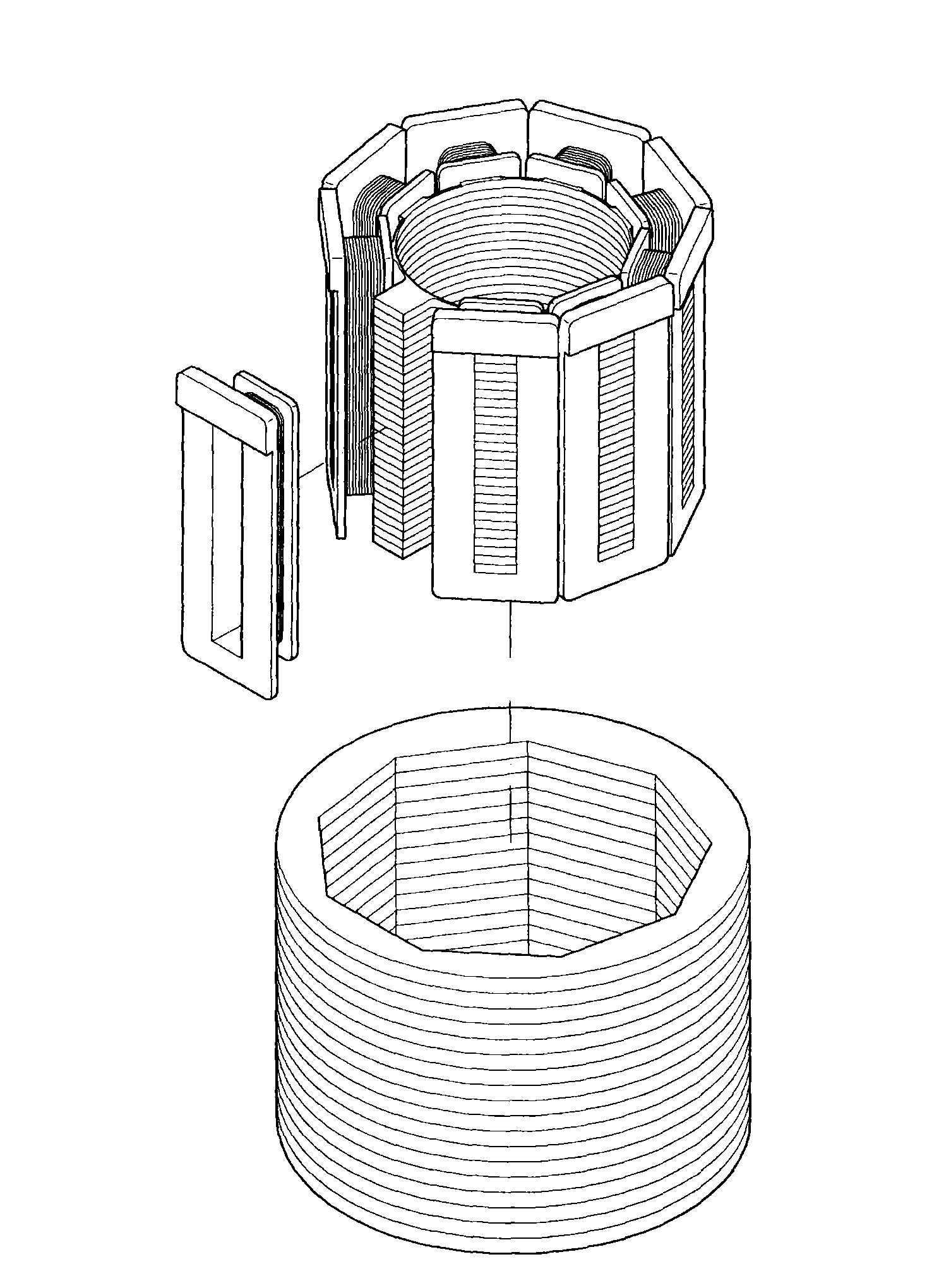

[0027] see Figure 4 As shown, it is a three-dimensional schematic diagram of the I-shaped monopole strips composed of the I-shaped monopole strips of the present invention. The manufacturing process of the motor stator of the present invention is firstly punching a plurality of silicon steel sheets with a precision I-shaped die to form a plurality of I-shaped monopole pieces 11, A plurality of I-type monopole sheets 11 are stacked one by one to form an I-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com