High-pressure slurry-casting ram pump piston system with split rear cover

A high-pressure grouting and plunger pump technology, which is applied in the field of plunger pumps and high-pressure grouting plunger pumps, can solve problems affecting the quality of engineering grouting and low machine efficiency, and achieve simple structure, good sealing performance, and reduced The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

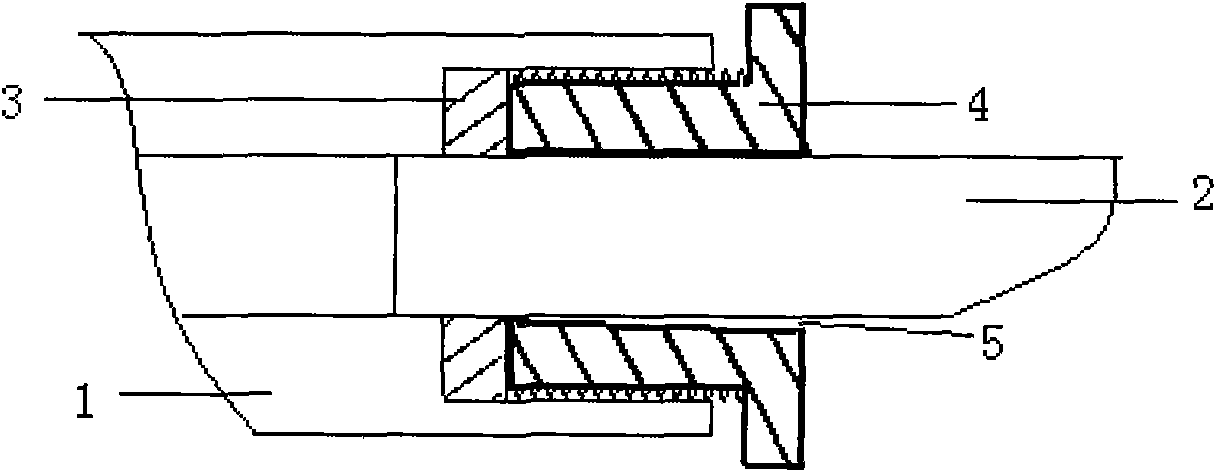

[0015] Such as figure 1 as shown,

[0016] The piston system of the prior art high-pressure grouting plunger pump includes a cylinder body 1, a piston rod 2, a sealing gasket 3, and a back cover 4, and the back cover is an integral part composed of a compression cover and a sleeve. There is a fit tolerance 5 between the back cover and the piston rod.

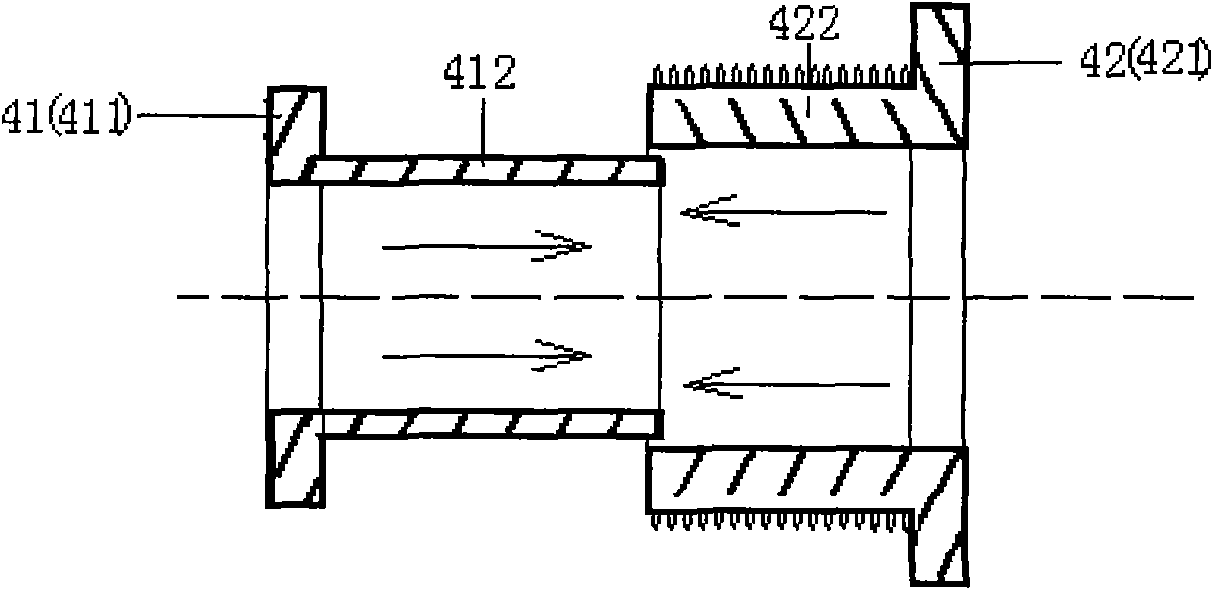

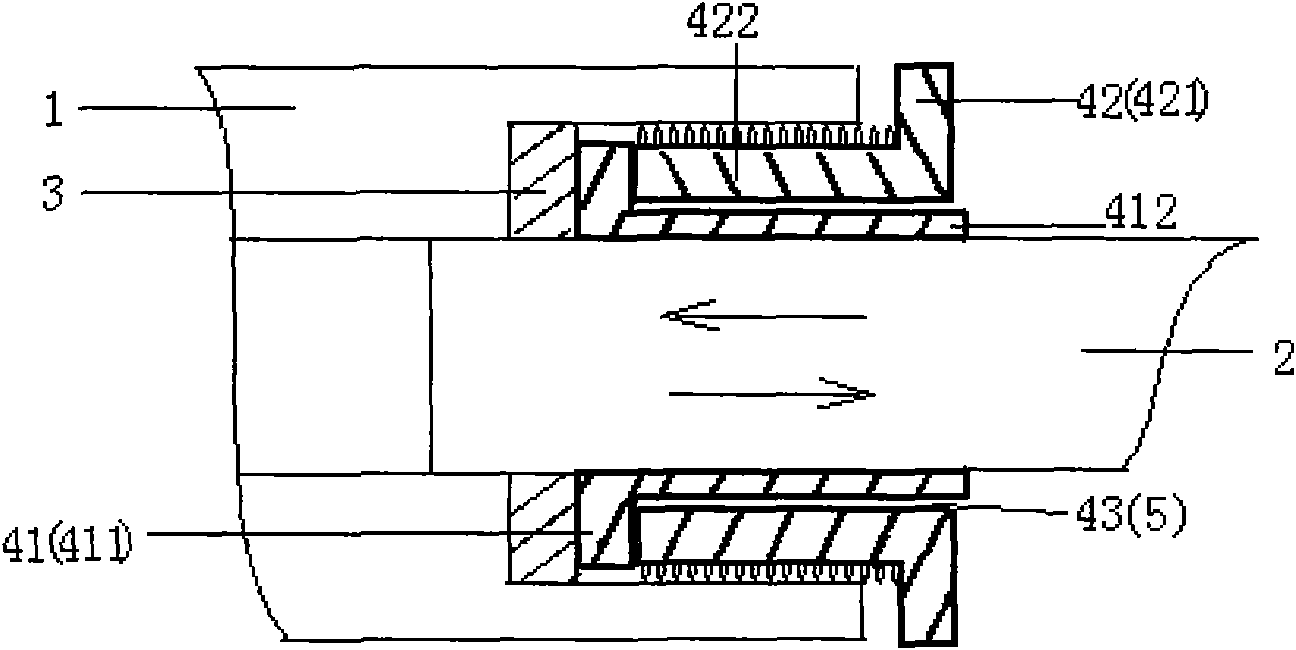

[0017] Such as figure 2 , 3 as shown,

[0018] In the present invention, the back cover is set as a separate integral part composed of an inner compression sleeve 41 and an outer compression sleeve 42, and the inner compression sleeve extends into the outer compression sleeve. The front gland 411 of the inner compression sleeve fits with the sealing gasket 3; the inner compression sleeve body 412 fits tightly on the outside of the piston rod 2, and extends into the outer compression sleeve as a whole, and the inner compression sleeve The end of the body is exposed outside the rear gland 421 of the outer compression sleeve;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com