Method for manufacturing fruit fiber mask

A production method and fruit fiber surface technology, which are applied in the directions of skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of artificial decomposition of non-woven fabrics, poor air permeability, side effects on the human body, etc., and achieve dry air. And the effect of high moisture vapor transmission rate, good adhesion and adsorption, and low irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

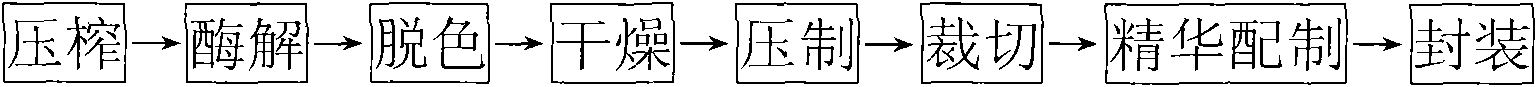

[0020] The following will combine figure 1 The present invention is further described:

[0021] A production method for a fruit fiber facial mask, which mainly includes the following production steps:

[0022] The first step: pressing: use fresh fruits (such as apples, oranges, strawberries, etc.) to press with a hydraulic press above 30 MPa (Mpa), remove more than 95% of water and pectin, and obtain relatively dry peel and pomace, or Directly use the remaining peel and pomace from fruit juice processing as raw materials for secondary processing;

[0023] Step 2: Enzymolysis: Use compound biologically active enzyme (BIO-A) as an auxiliary material, put it into the enzymolysis tank together with the peel and pomace, and enzymolyze it for more than 72 hours to promote the breakage of carbon-hydrogen bonds and break the bonded state, thereby Completely decomposed into fiber state;

[0024] The third step: decolorization: use activated carbon decolorizer to decolorize the fruit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com