Spacer of pair glass

A double-layer glass and spacer technology, applied in windows/doors, building components, buildings, etc., can solve problems such as corrosion, glass surface and spacer support frame and spacer separation, through-hole size increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

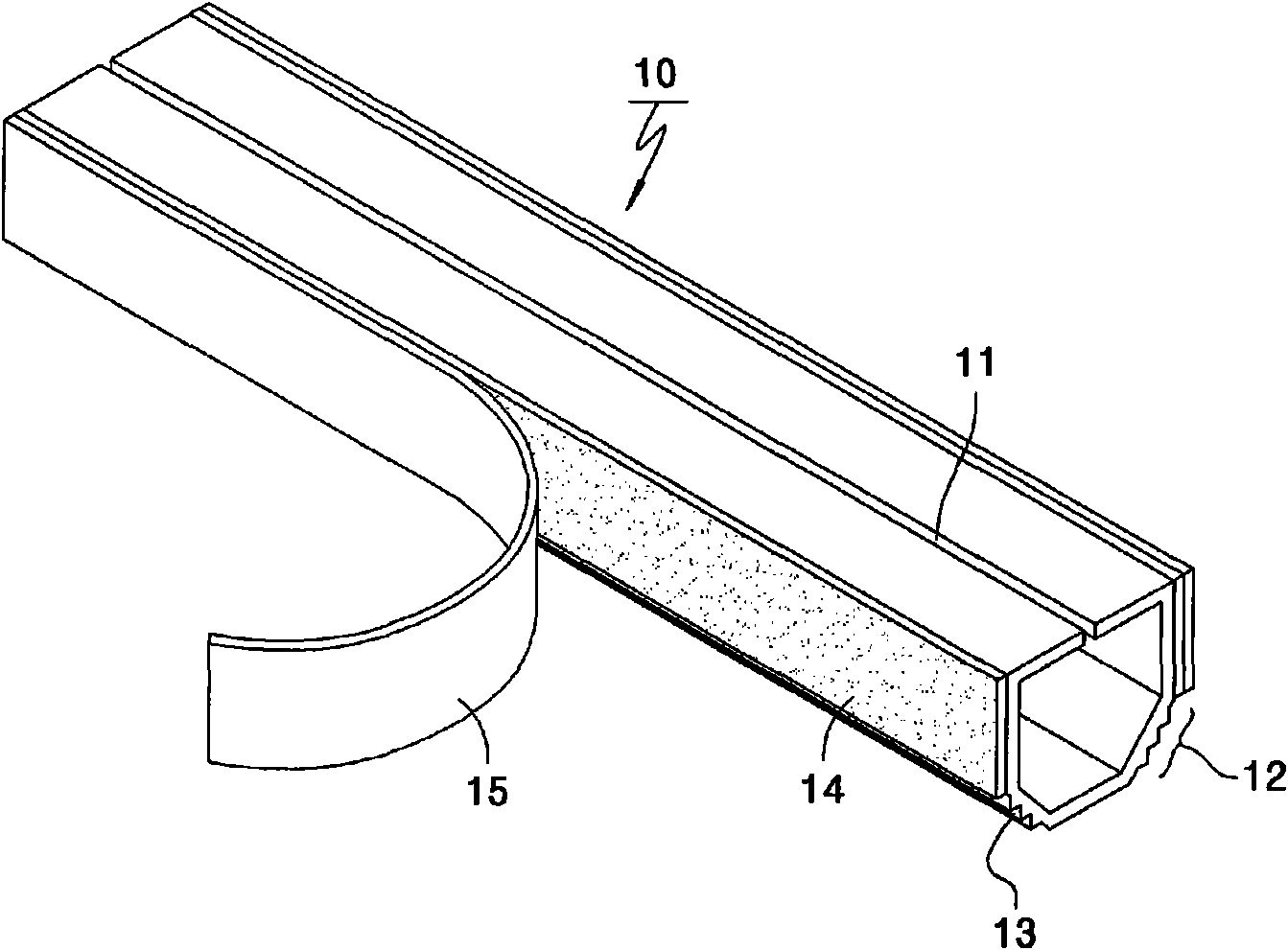

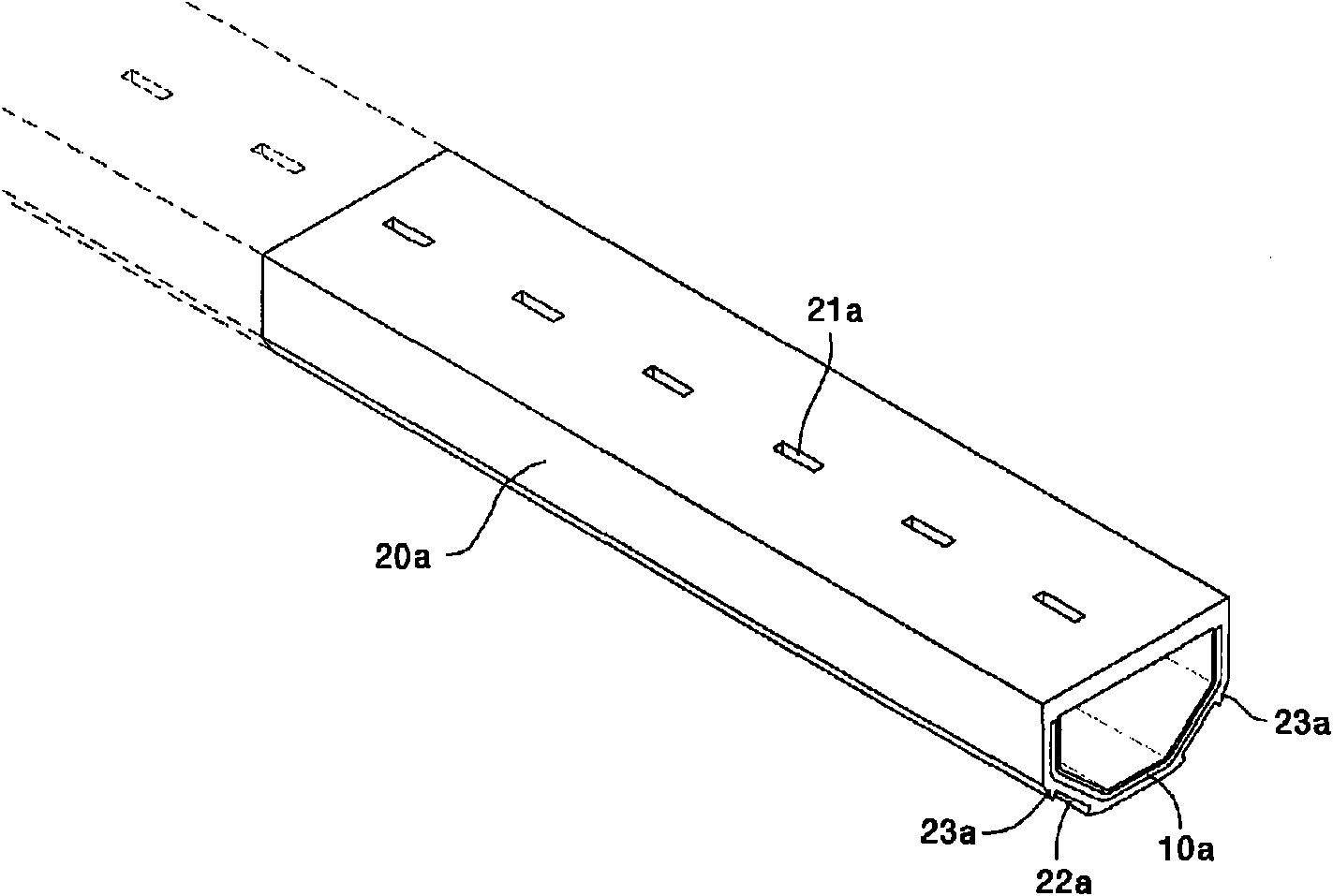

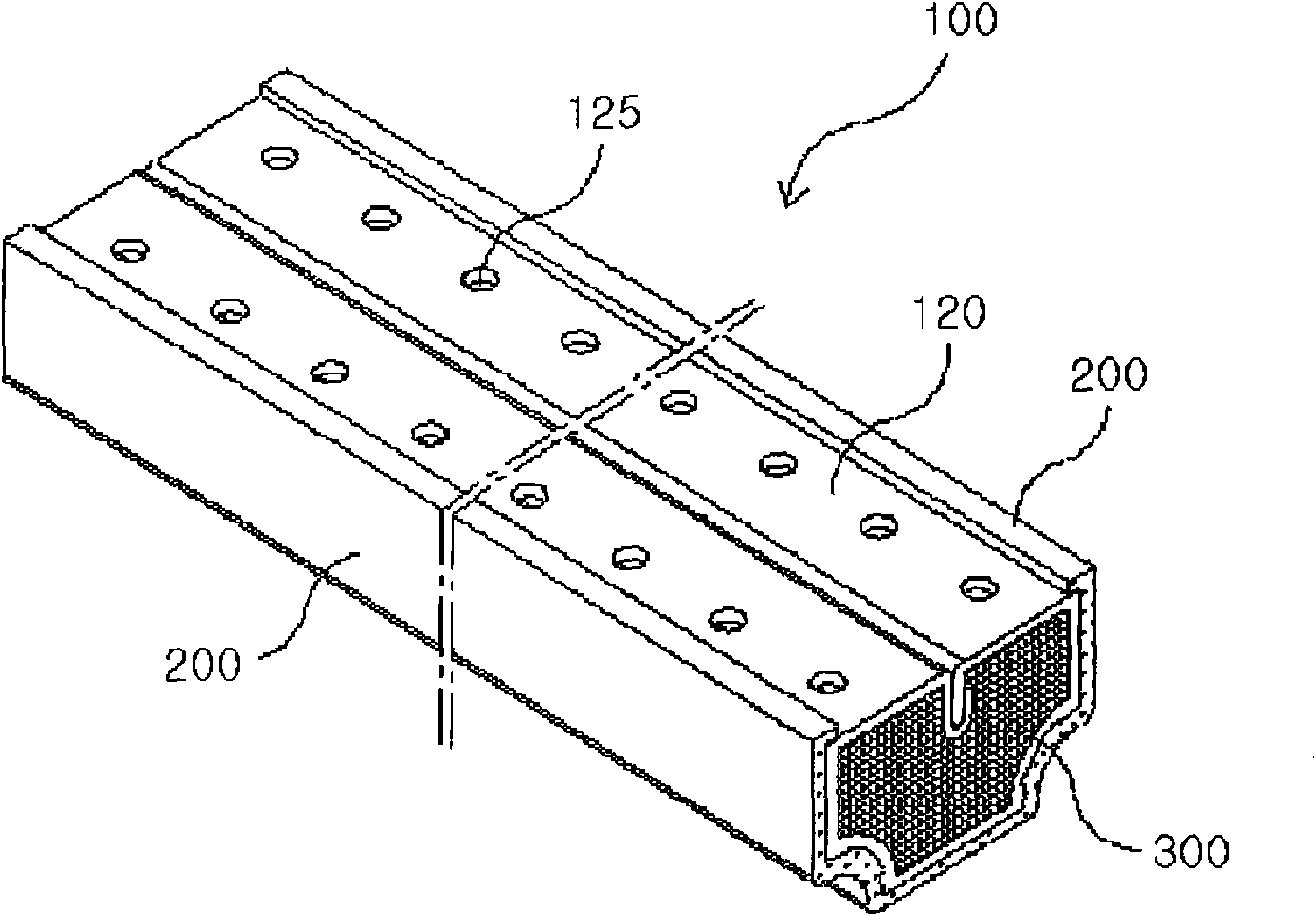

[0037] The present invention is as figure 1 with figure 2 The existing spacer bar shown is composed of the upper surface 120, the two side surfaces 130, the inclined surface 140 and the bottom surface 150, and a space part 110 is provided in the inside of the section, and the above-mentioned inclined surface 140 forms a curved part at the part where the two sides and the bottom surface are connected. , protruding reinforcement members 145 are formed at both ends of the above-mentioned inclined surface 140, and the above-mentioned upper surface 120 is provided with a plurality of through holes 125 at a certain interval in the general double-layer glass spacer 100, such as image 3 As described above, a double-layer glass spacer (hereinafter referred to as "spacer") provided with an integrated heat shield 200 covering the two side surfaces 130, the inclined surface 140 and the bottom surface 150 except the upper surface 120 is provided.

[0038] Such as Figure 5 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com