Substrate transfer system and transfer method

A transfer system and substrate technology, applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems that cannot meet the needs of production, achieve the effect of improving efficiency, long improvement cycle, and satisfying the improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

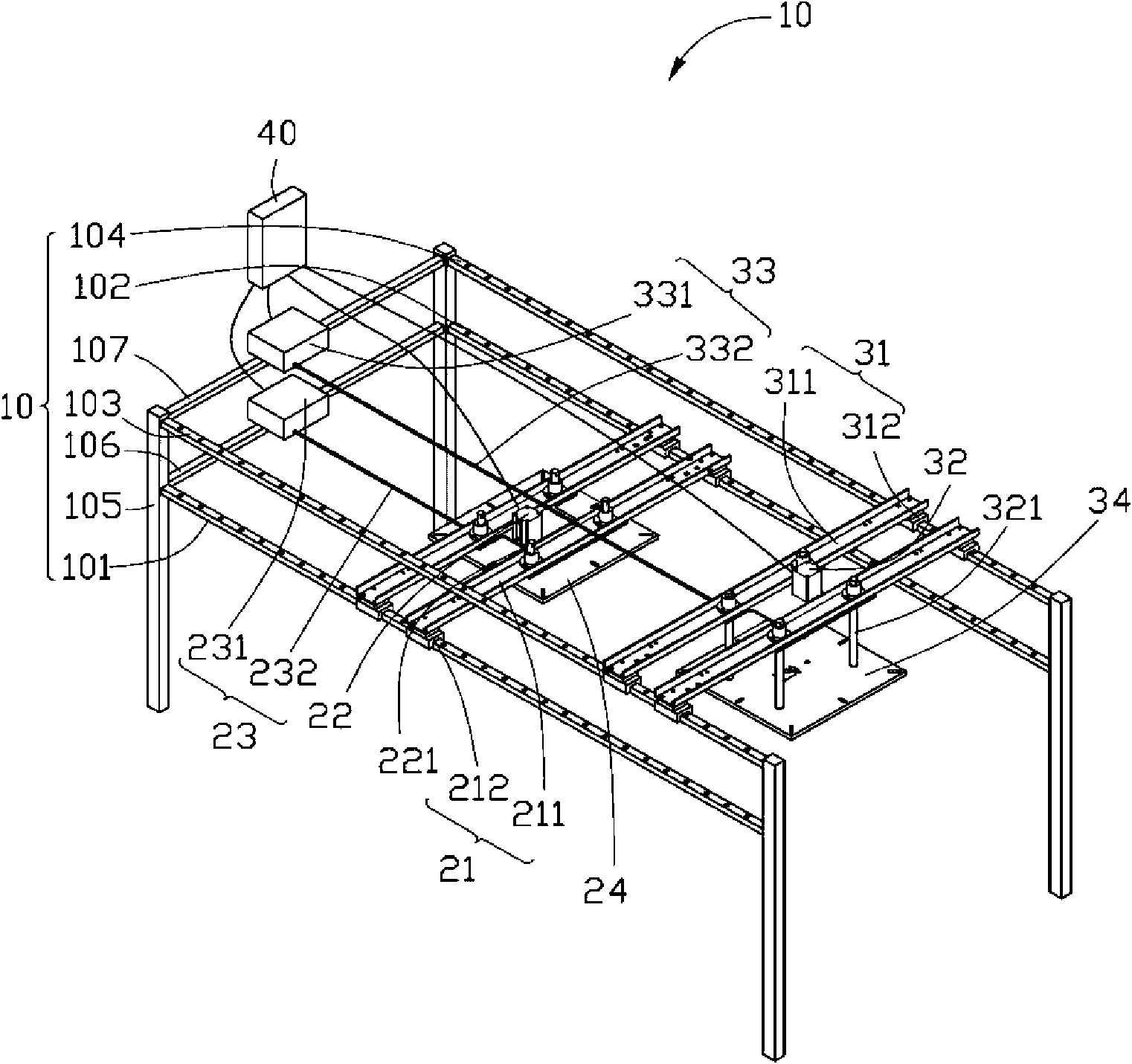

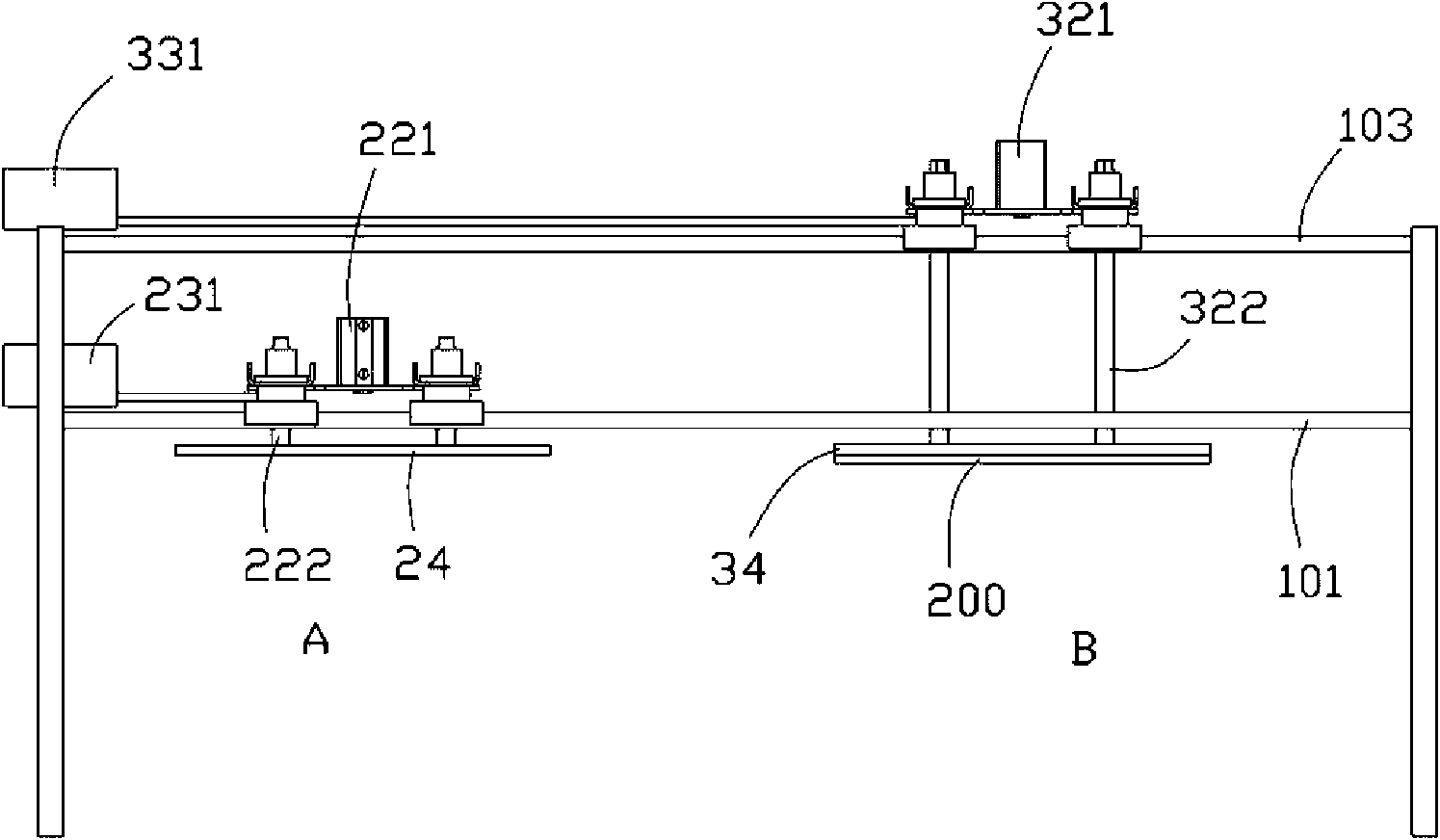

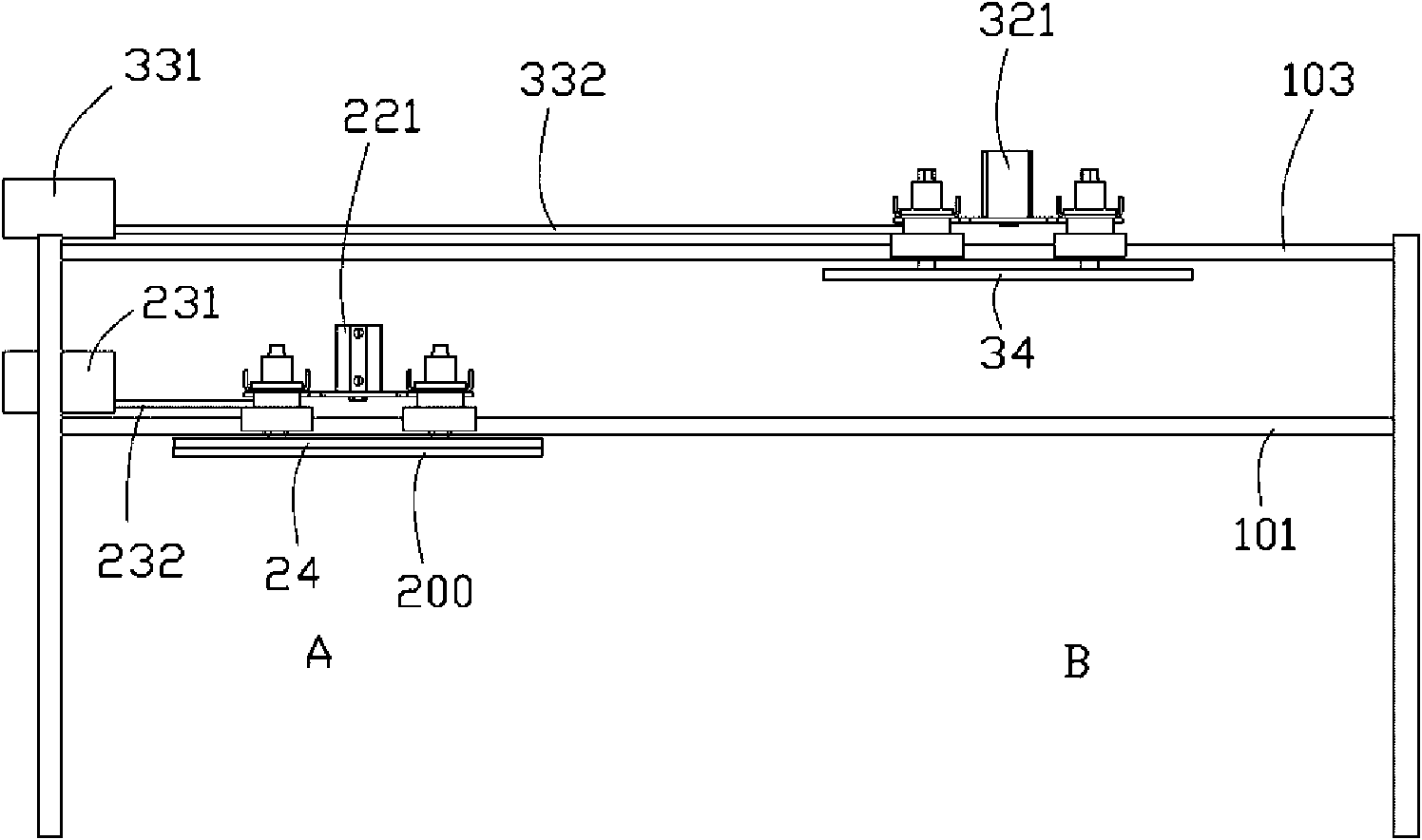

[0012] The technical solutions provided by this technical solution will be further described in detail below in conjunction with the accompanying drawings.

[0013] see figure 1 and figure 2 The embodiment of the technical solution provides a substrate transfer system 100, which includes a frame 10, a first driving device 22, a second driving device 23, a third driving device 32, a fourth driving device 33, a first adsorption device 24, The second adsorption device 34 , the first slider 21 and the second slider 31 .

[0014] The rack 10 includes a first guide rail 101 , a second guide rail 102 , a third guide rail 103 , a fourth guide rail 104 , four support rods 105 , a first connecting rod 106 and a second connecting rod 107 .

[0015] The first guide rail 101, the second guide rail 102, the third guide rail 103 and the fourth guide rail 104 are horizontally arranged and parallel to each other, wherein the first guide rail 101 and the second guide rail 102 are located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com