LED electrode structure

An electrode structure and electrode technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as uneven luminous brightness, low conductivity, and uneven current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

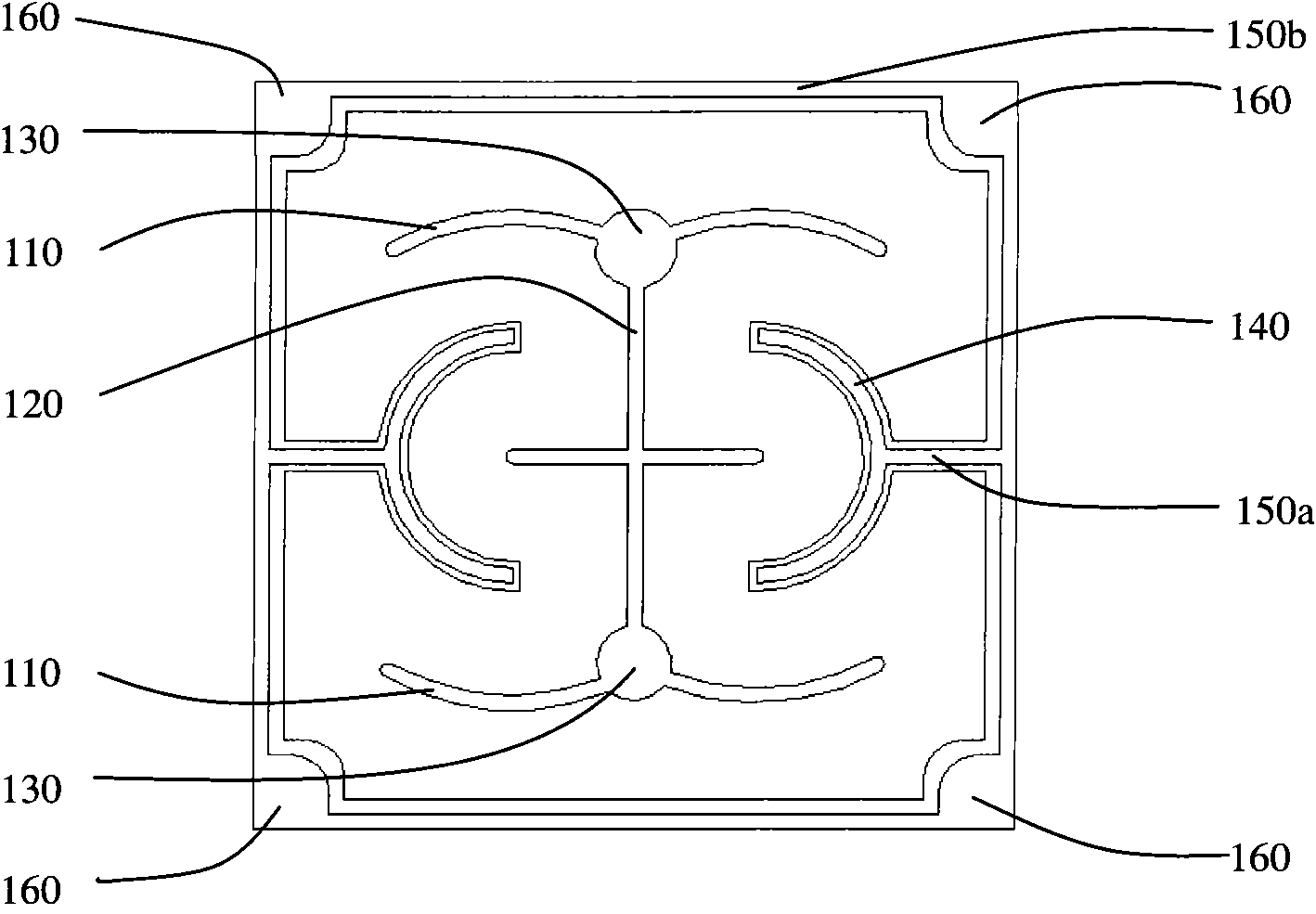

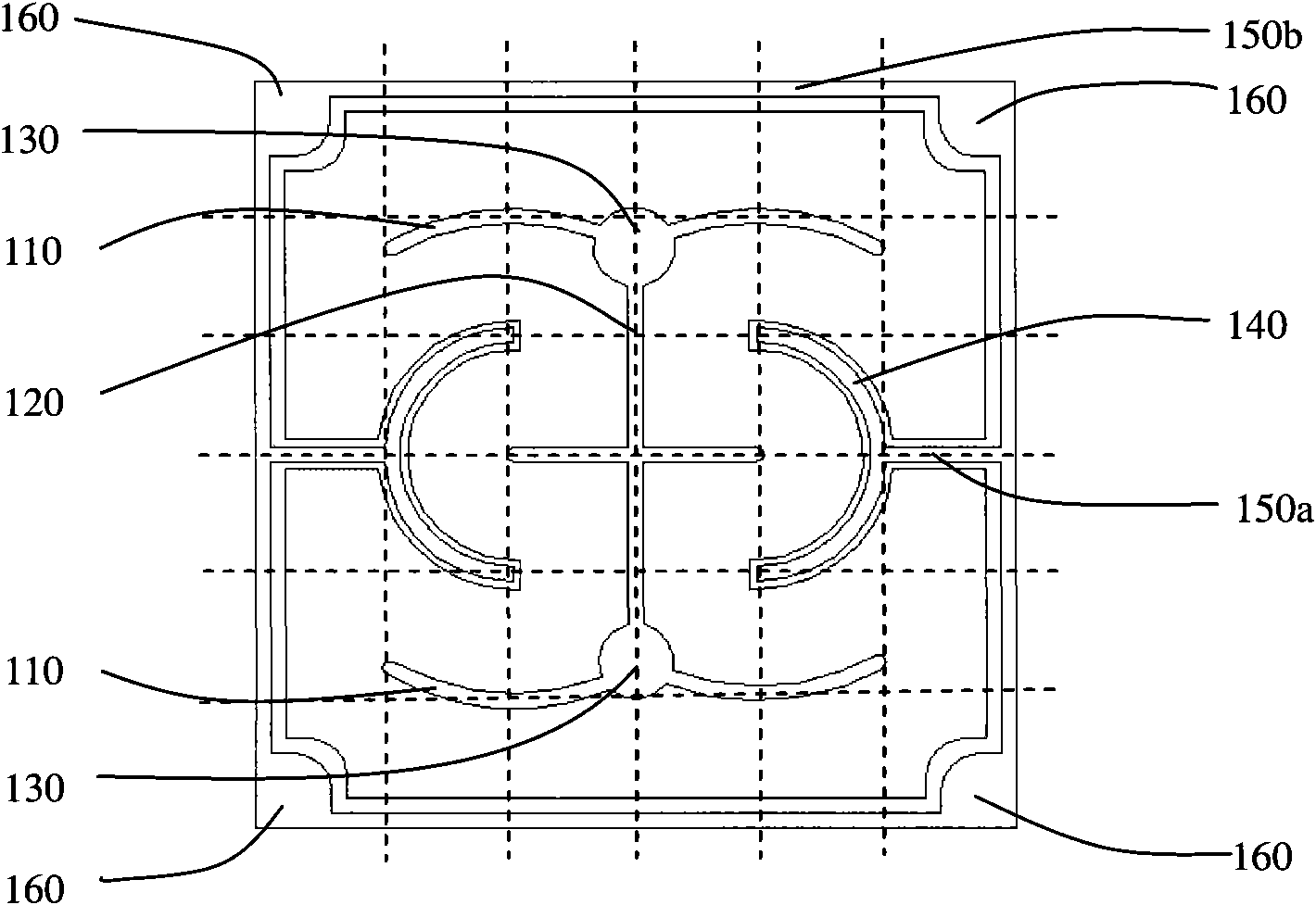

[0037] Figure 1a It is a schematic diagram of Embodiment 1 of the first LED electrode structure provided by the present invention. The first electrode includes four first ring finger parts 110 with the same radius, a "cross" shaped first connecting part 120 connecting the four first ring finger parts 110 and at least one first contact part 130, These three parts constitute a first electrode that deforms and bends the word "King". The first contact portion 130 can be inserted at the connection between the first connecting portion 120 and the first ring finger portion 110 , and can also be inserted at any other position on the first ring finger 110 . In this embodiment, two circular first contact portions 130 are respectively inserted into the joints of the first connection portion 120 and the first ring finger portion 110 to form metal contact pads. It should be emphasized that the shape of the first contact portion 130 in this embodiment is not limited to a circle, and may a...

Embodiment 2

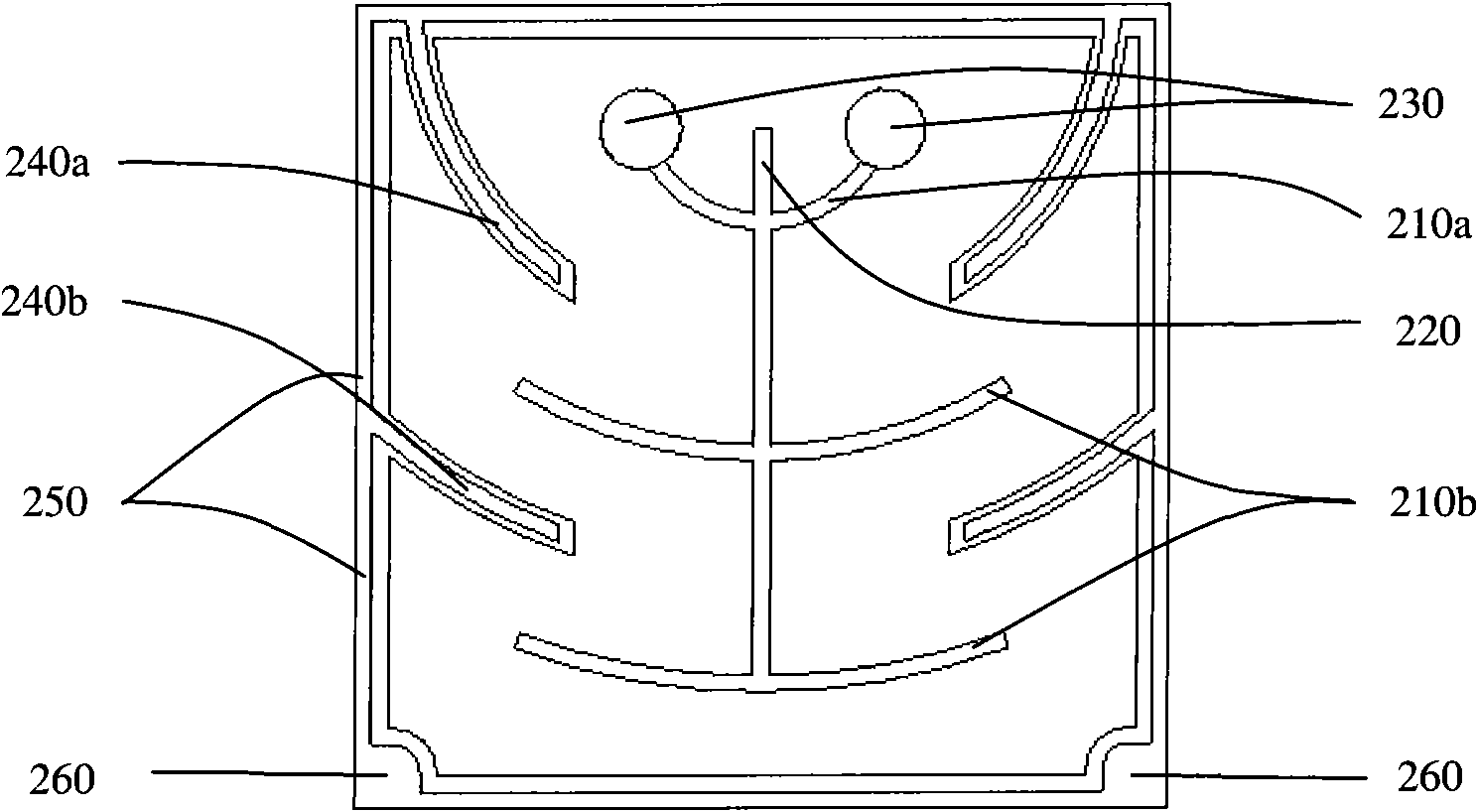

[0041] figure 2It is a schematic diagram of the second embodiment of the first LED electrode structure provided by the present invention. The first electrode includes first ring finger parts 210a and 210b, a first connecting part 220 connecting the first ring finger parts 210a and 210b, and at least one first contact part 230. The first electrode of the word "King". In this specific embodiment, two circular first contact portions 230 are located at the fingertip portion of the first ring finger portion 210a and form metal contact pads. It should be emphasized that the shape of the first contact portion 230 in this embodiment is not limited to a circle, and may also be a geometric figure such as an ellipse or a rectangle.

[0042] The second electrode includes two second ring finger portions 240 a and 240 b with different radii, a second connection portion 250 connecting the second ring finger portion 240 , and at least one second contact portion 260 . Wherein the second co...

Embodiment 3

[0046] image 3 It is a schematic diagram of Embodiment 3 of the third LED electrode structure provided by the present invention. The first electrode includes first ring finger parts 310a and 310b, first connecting parts 320a, 320b and 320c connecting the first ring finger parts 310a and 310b, and at least one first contact part 330. These three parts form a deformed ring shape. Bend "M" on the first electrode. In this specific embodiment, two circular first contact portions 330 are located in the middle of the ring finger of the first ring finger portion 310a and form metal contact pads. It should be emphasized that the shape of the first contact portion 230 in this embodiment is not limited to a circle, and may also be a geometric figure such as an ellipse or a rectangle.

[0047] The second electrode includes a second ring finger portion 340 , second connection portions 350 a , 350 b connecting the second ring finger portion 340 , and at least one second contact portion 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com