Magnetic particles preparation method by using nanometer spherical polyelectrolyte brush as micro-reactor

A technology of polyelectrolyte brushes and microreactors, which can be applied to magnetic materials, magnetic objects, circuits, etc., and can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

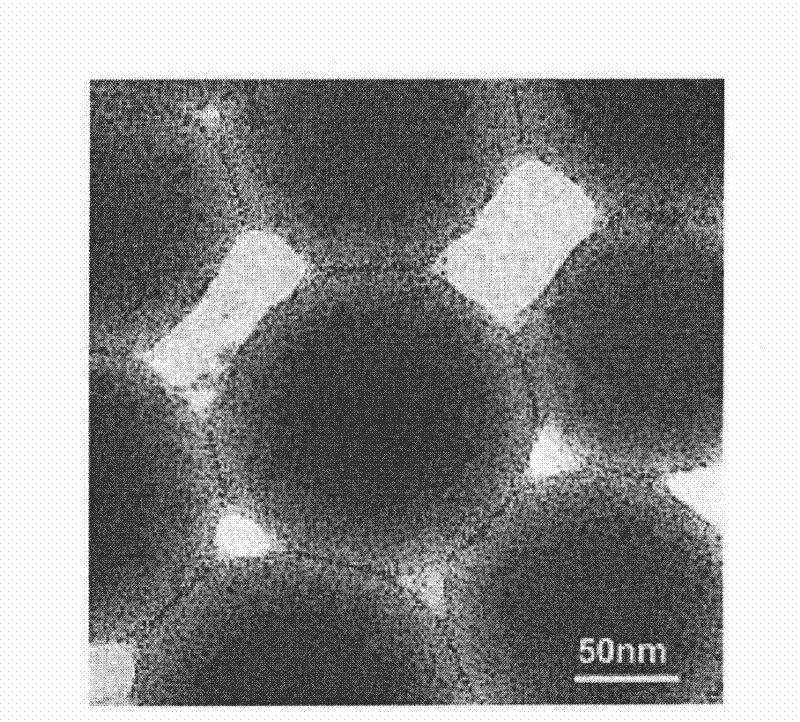

[0025] Embodiment 1 miniemulsion polymerization prepares spherical polyelectrolyte brush inner core

[0026] Mix 0.40 g of n-hexadecane, 0.30 g of azobisisobutyronitrile and 10.0 g of styrene monomer into deionized water dissolved with 0.12 g of sodium dodecylsulfonate, and ultrasonically pre-emulsify in an ice bath for 2 After 2 hours of fine emulsification, the temperature was raised to 65° C. under a nitrogen atmosphere, the stirring rate was controlled at 400 rpm, and the polymerization reaction was carried out for 3 hours to obtain a spherical polyelectrolyte brush inner core.

Embodiment 2

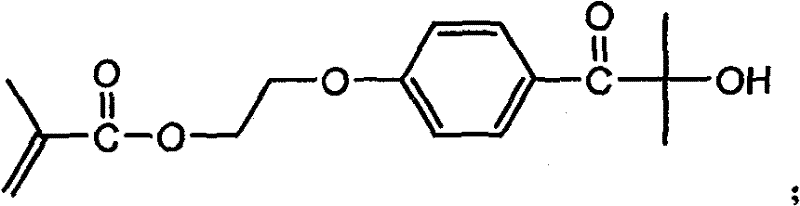

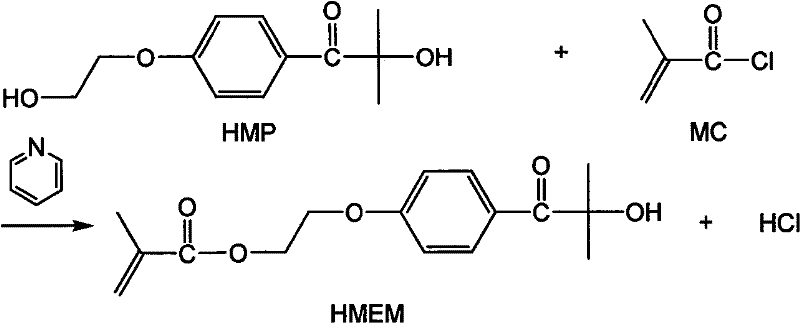

[0027] Embodiment 2 Schotten-Baumann reaction prepares photoinitiator HMEM

[0028] Pour 30.0g of photoinitiator HMP into a 500ml single-necked flask, add 150ml of acetone, stir until HMP is completely dissolved, then add 10g of newly purified pyridine, continue stirring at low temperature, and then add 13.6g of methacryloyl chloride (MC ) was dissolved in 50ml of acetone, and slowly added dropwise to the reaction flask, and reacted at room temperature for 12 hours after the dropwise addition, to obtain an orange liquid, filtered to remove the beige precipitate at the bottom, and obtained pure HMEM photoinitiated by chromatography agent.

Embodiment 3

[0029] Embodiment 3 prepares the spherical polyelectrolyte brush inner core that photoinitiator coats

[0030] At the end of the miniemulsion polymerization reaction in Example 1, slowly add 1g of photoinitiator HMEM dropwise to the reaction system, and the rate of addition is controlled at 10 drops / minute; after the addition is completed, react for 3 hours; obtain the photoinitiator-coated Spherical polyelectrolyte brush inner core, dynamic light scattering (DLS) characterization results show that the hydrodynamic diameter of the spherical polyelectrolyte brush inner core is 190nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com