Method for adjusting deviation of plate blank of walking furnace by phase method

A technology of stepping heating furnace and phase method, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of slab deviation, slab hitting furnace wall, etc., so as to prevent accidents and avoid hitting furnace wall. effect of phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Principle of the present invention:

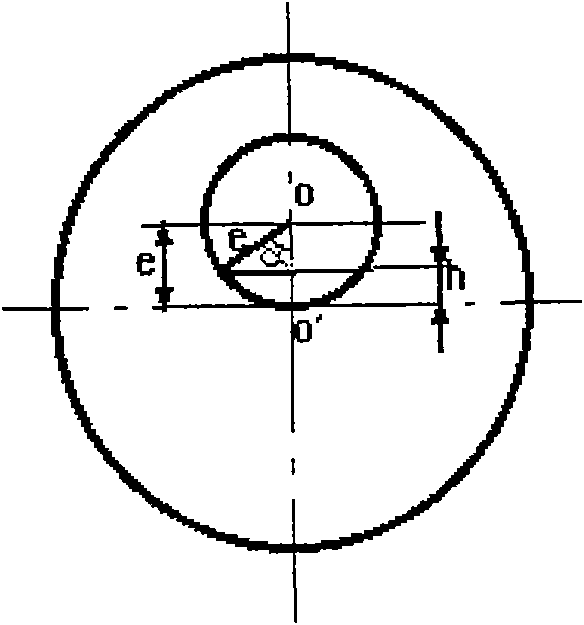

[0013] 1. The relationship between the rotation angle of the eccentric wheel and the lifting amount of the walking beam

[0014] Such as figure 1 As shown, the lifting amount of the walking beam is the lifting amount of the outer circle center O' of the eccentric wheel, from figure 1 It can be concluded that the relationship between the rotation angle of the eccentric wheel and the lifting amount of the walking beam is:

[0015] h=e(1-Cosα)(1-1)

[0016] In the formula:

[0017] h- walking beam lifting amount

[0018] e-Eccentric amount of eccentric wheel

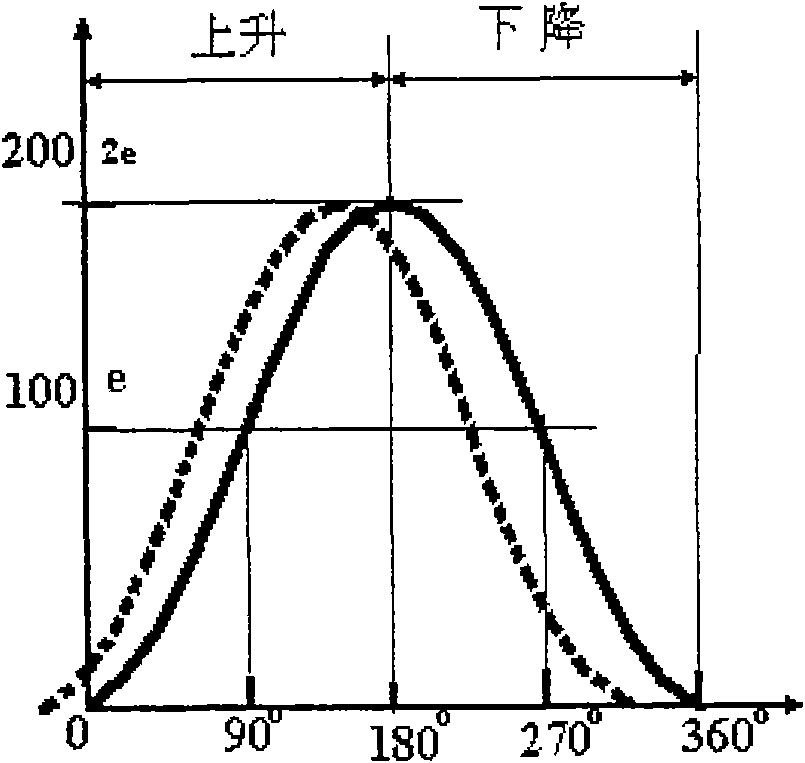

[0019] α-rotation angle of eccentric wheel

[0020] Make e=100, the fixed beam elevation is +800, the elevation of the movable beam is +700 at the lower limit, and the elevation at the upper limit is +900, that is, the movable beam contacts the slab when it rises by 100 (the above parameters are Taiyuan Steel 1549mm hot rolling mill 1# heating furnace parameters). Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com