Formulation of electroforming solution, preparation method of electroforming solution and process control condition of electroforming solution

A technology of electroforming liquid and conditions, applied in electroforming, electrolysis process, etc., can solve the problems of insufficient hardness and low product thickness, and achieve the effect of reducing expenditure, easy purchase and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

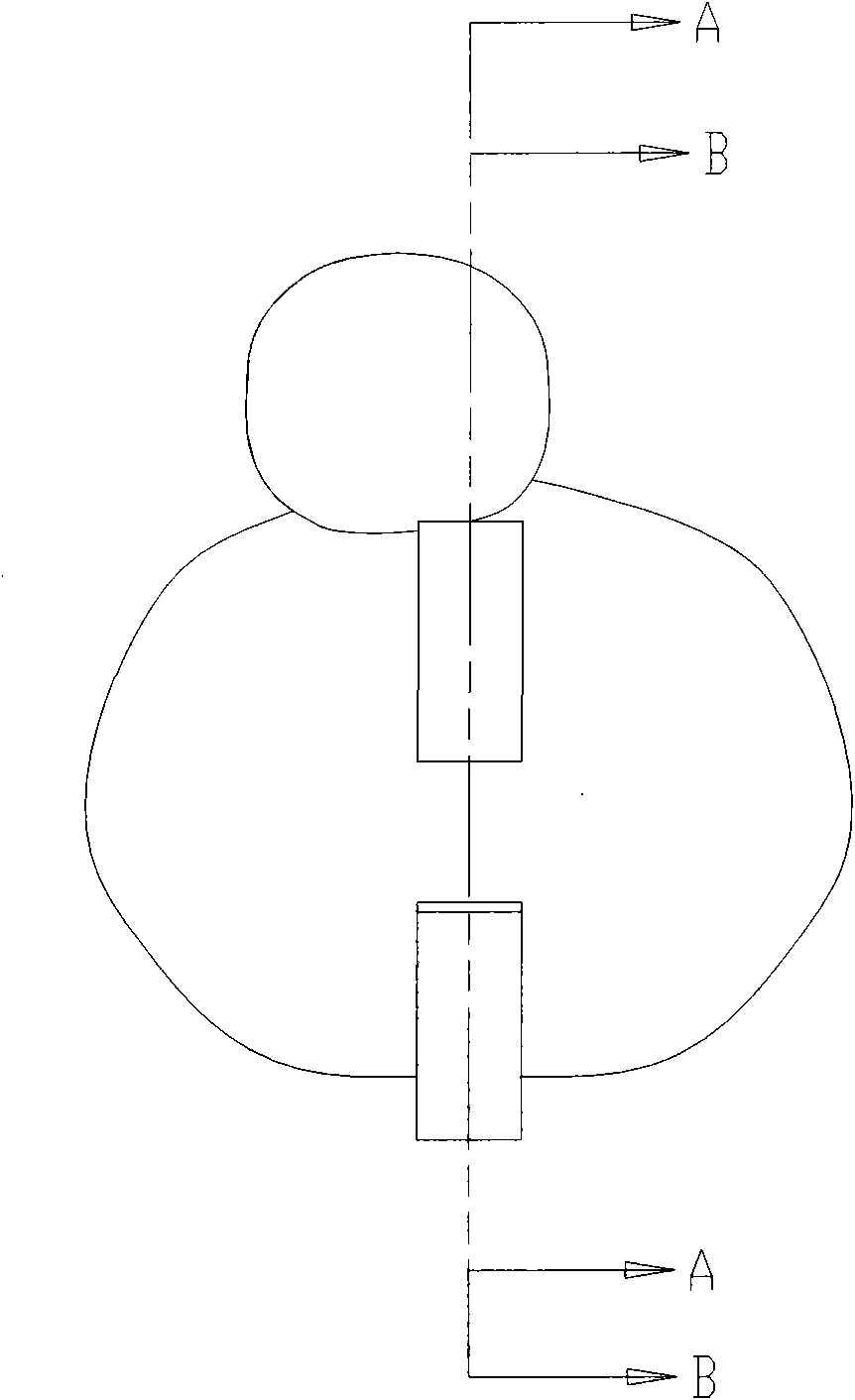

Image

Examples

Embodiment Construction

[0040] In the first embodiment of the formula of the BT48 hard gold electroforming liquid of the present invention and the electroforming process control conditions (hereinafter referred to as the present invention) of the preparation method of the electroforming liquid and the electroforming liquid, the electroforming liquid of the present invention is Aqueous solution of potassium aurous cyanide, cracking salt and additives, wherein the cracking salt includes potassium citrate, potassium sodium tartrate, disodium ethylenediamine tetraacetate, boric acid and hardening agent, the additive is a smoothing agent, electric The casting solution consists of the following components:

[0041] Potassium aurous cyanide g / L 20~30

[0042] Potassium citrate g / L 50~70

[0043] Potassium sodium tartrate g / L 5~20

[0044] Disodium edetate g / L 10~20

[0045] Boric acid g / L 10~20

[0046] Hardener g / L 10~20

[0047] Smoothing agent g / L 0.5~5

[0048] Because the electroforming liquid wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com