Cutting device of LCD panel

A liquid crystal panel and cutting device technology, which is applied to glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reduced device operation rate and increased cost, and achieve the effect of reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

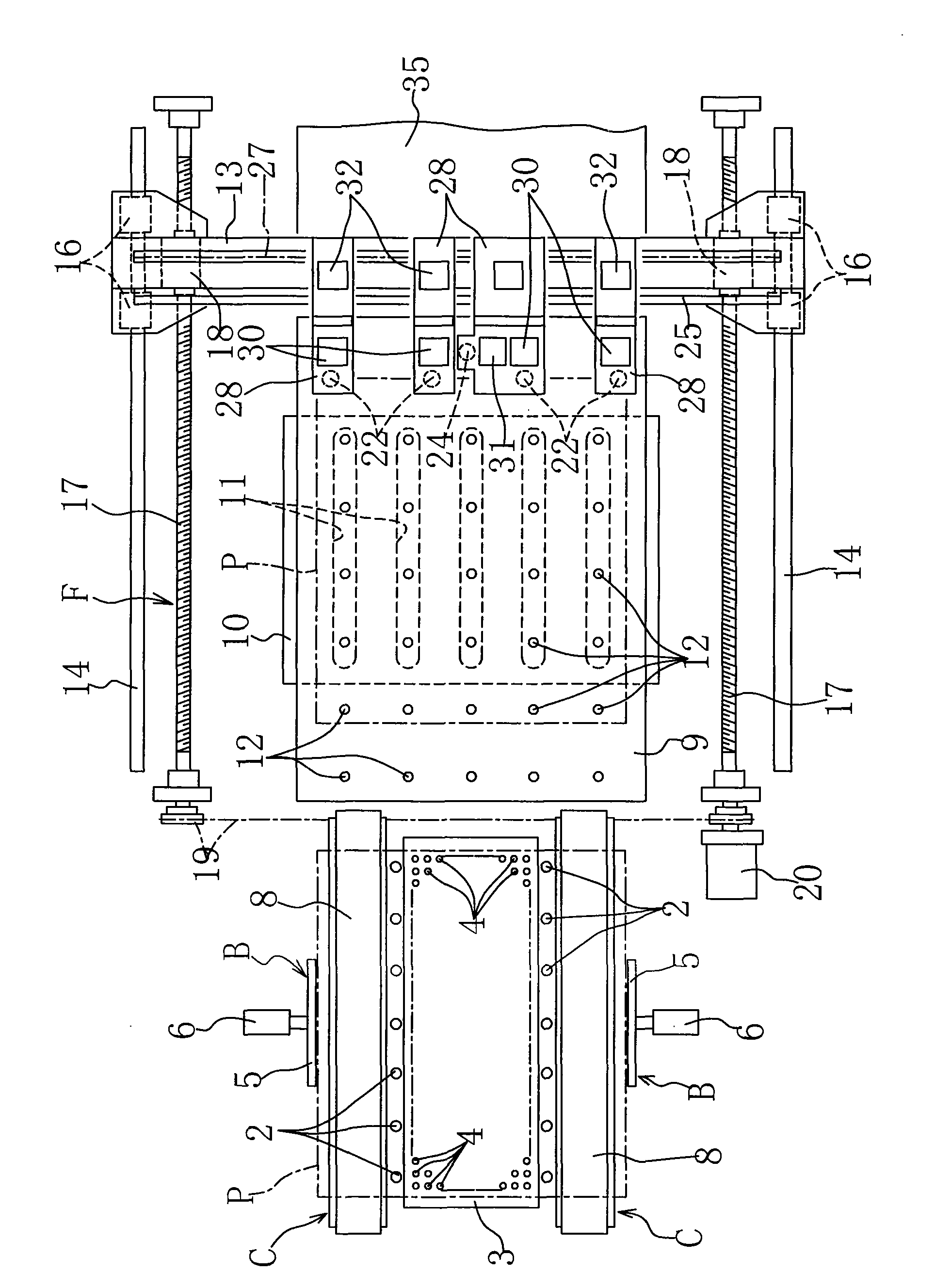

[0051] Embodiments of the present invention will be described with reference to appended drawings.

[0052] During the embodiment of the present invention, as Figure 1 to Figure 5 As shown, A is a supply platform for receiving large-scale liquid crystal panels P in a horizontal posture. The supply platform A is equipped with an adjustment means B for adjusting the received liquid crystal panels P, and the adjusted The liquid crystal panel P is supplied to the carrying-in means C ahead.

[0053] The charging of the above-mentioned liquid crystal panel P is as follows: Figure 6 Shown, to utilize the elongation of cylinder 1 to rise (as Figure 6 After the plurality of rows of pins 2 shown in the figure) are collected from the lower surface of the liquid crystal panel P dropped by the manipulator R, etc., the pins 2 are lowered by the contraction of the cylinder 1 and collected on the stage 3.

[0054] Thereafter, the liquid crystal panel P on the stage 3 is floated while th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com