Battery with a heat conducting plate

A heat conduction plate and battery technology, which is applied to small-sized batteries/battery packs, secondary batteries, battery pack components, etc., can solve the problems of reducing the effective heat conduction cross-section of the heat conduction plate and reducing the possible efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

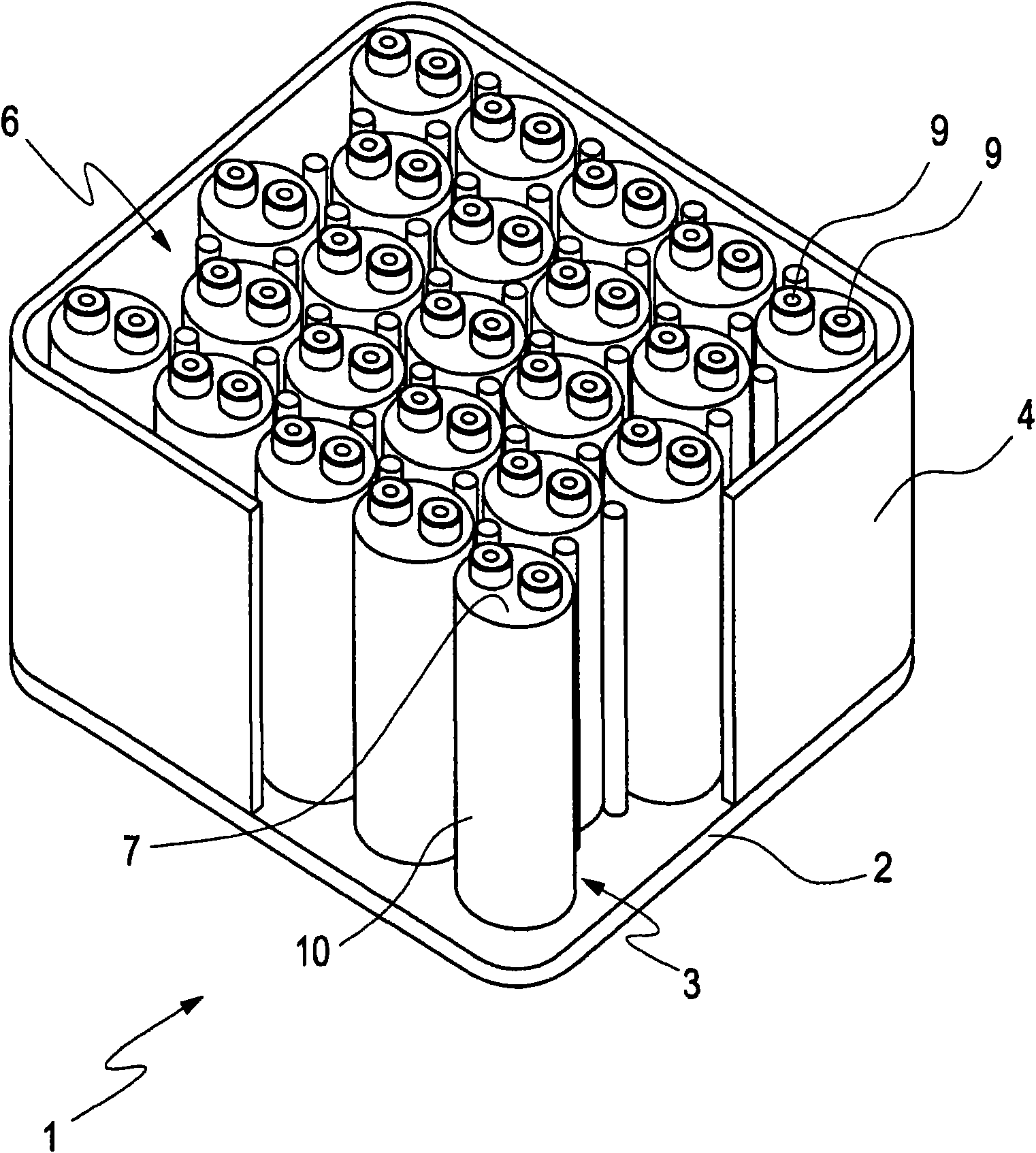

[0020] in figure 1 A conventional battery 1 is shown, which has a heat conducting plate 2 arranged on the bottom side. The battery 1 also has a plurality of cells 3 electrically connected to each other. The cell 3, which is preferably circular in cross-section, is arranged in a particularly completely enclosed battery housing 4. In the battery casing 4, the cell 3 is thermally placed on a thermally conductive plate 2 designed as a metal plate. The heat conducting plate 2 is provided with a cooling channel 5 for guiding the heat conducting medium. The cells 3 are arranged on the heat conducting plate 2 in such a way that their longitudinal axes are parallel to each other.

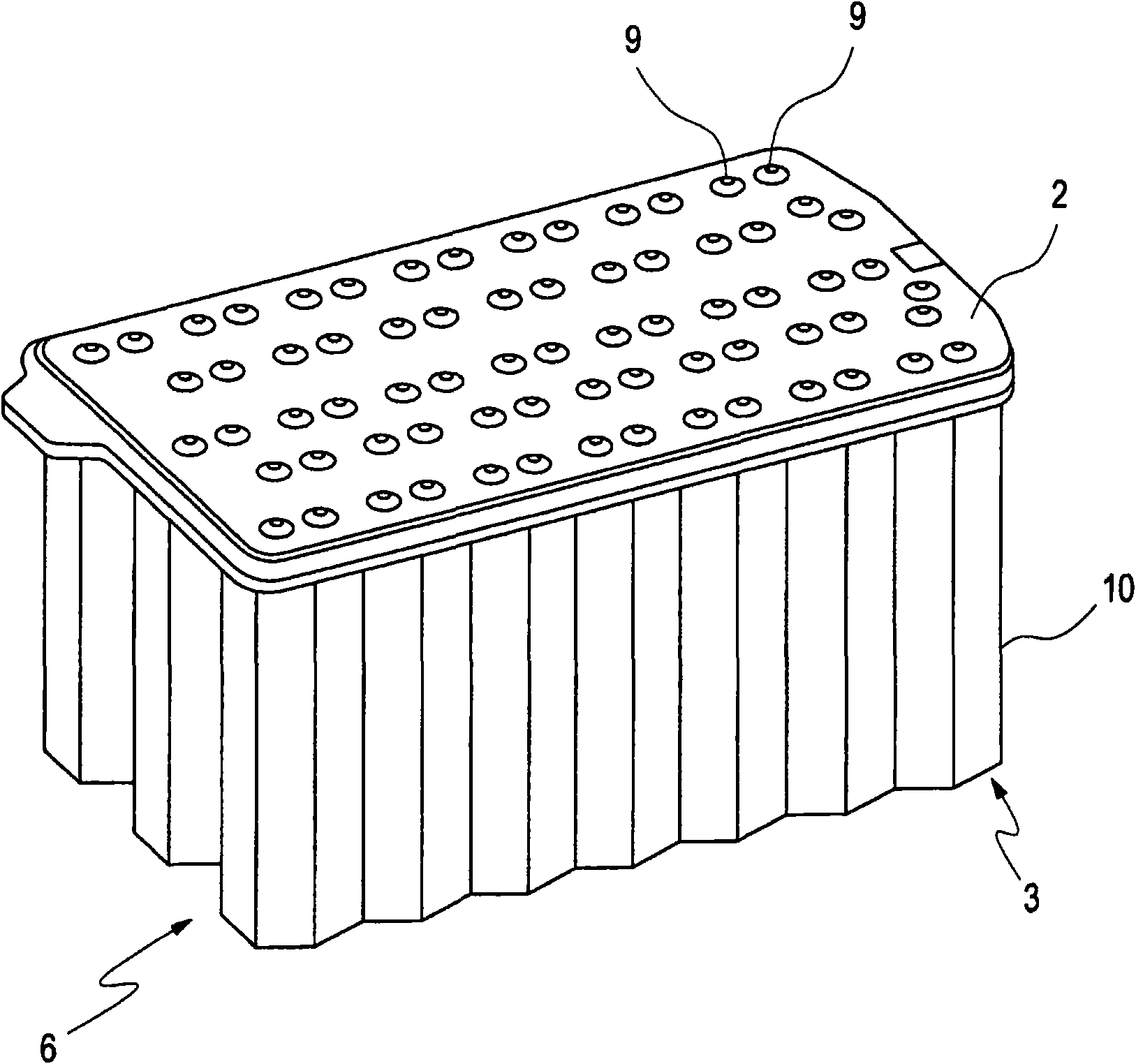

[0021] in figure 2 The middle is a perspective view showing a cell group 6 composed of a plurality of cells 3 of the battery according to the present invention, with a heat conducting plate 2 arranged on the top side and a cell 3 thermally connected to the heat conducting plate. Particularly due to the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com