Micropower power supply converting circuit

A power conversion and micro-power technology, which is applied in the output power conversion device, the conversion of DC power input to DC power output, and the adjustment of electrical variables, etc. , large isolation capacitance, etc., to achieve the effect of ensuring reliability and stability, high mean time between failures, and high isolation voltage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

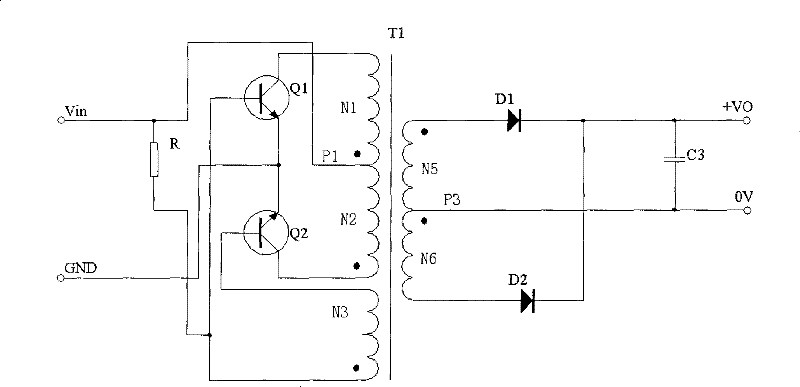

[0030] For the circuit diagram of the first embodiment of the micropower power conversion circuit, see figure 2 As shown, it includes a first resistance circuit, a first capacitor circuit, a second capacitor circuit, a first switching transistor Q1, a second switching transistor Q2, a transformer T1, a first diode D1, a second diode D2, and a second diode. The second resistance circuit, the third capacitor circuit, where figure 2 The first resistance circuit in the middle includes the first resistance R1, but the embodiment of the present invention does not limit the first resistance circuit to only include the first resistance, and multiple resistances can also be combined with circuits to achieve the same function as the first resistance; figure 2 The first capacitor circuit includes a first capacitor C1, the second capacitor circuit includes a second capacitor C2, and the third capacitor circuit includes a third capacitor C3; however, the embodiment of the present invention ...

Embodiment 2

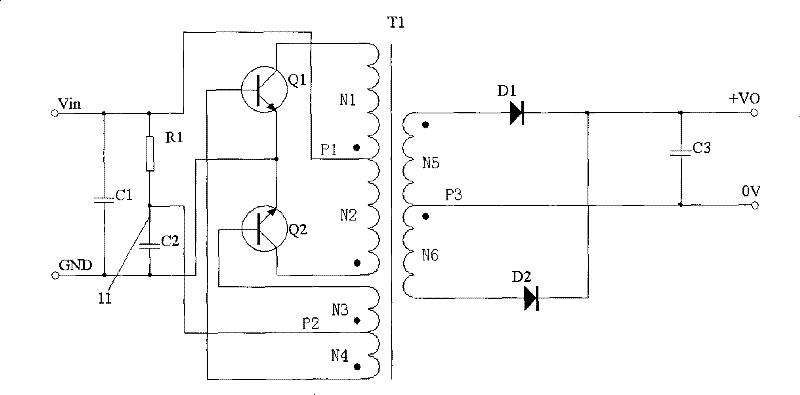

[0051] Such as Figure 5 As shown, in order to further improve the present invention, figure 2 On the basis of the illustrated embodiment, the micro-power power conversion circuit adds a second resistor circuit, and the second resistor circuit includes a second resistor R2; however, the embodiment of the present invention does not limit the second resistor circuit to only include the second resistor. It is also possible to combine multiple resistors to achieve the same function as the second resistor. One end of the second resistance circuit is connected to the first connection line 11, and the other end of the second resistance circuit is connected to the second tap P2. The working principle is that at the moment of starting, the second resistance R2 absorbs the energy of the third winding N3 and the fourth winding N4 to Reduce the base driving voltage of the switching transistor, prevent the switching transistor from entering deep saturation, and improve the starting performa...

Embodiment 3

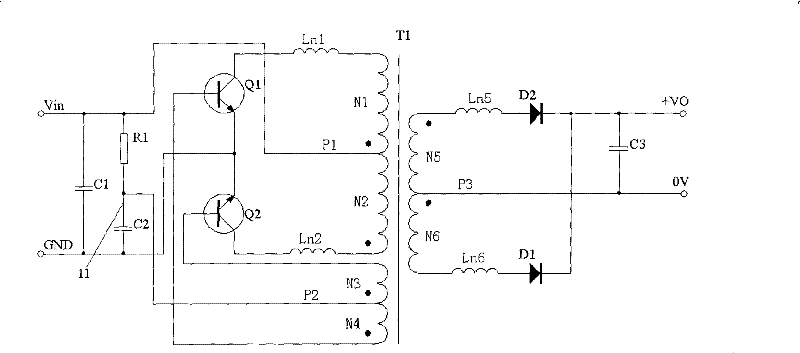

[0053] Such as Image 6 As shown, in order to further improve the present invention, figure 2 On the basis of the illustrated embodiment, the micropower power conversion circuit adds a third resistor circuit, and the third resistor circuit includes a third resistor R3; however, the embodiment of the present invention does not limit the third resistor circuit to only include a third resistor. It is also possible to combine multiple resistors to achieve the same function as the third resistor. The third resistance circuit is connected in parallel at both ends of the output terminal, mainly to prevent the output voltage of the product from increasing due to load changes when the product is no-load, and to improve the output characteristics of the product under light load and no-load conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com