Laminated bus bar

A technology of laminated busbars and insulating layers, which is applied in the direction of electrical components, root rods/rods/wires/strip conductors, coupling devices, etc., can solve the problems of large structure, inconvenient installation and maintenance, and high inductance coefficient, so as to reduce system noise , easy installation and on-site maintenance, the effect of small impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

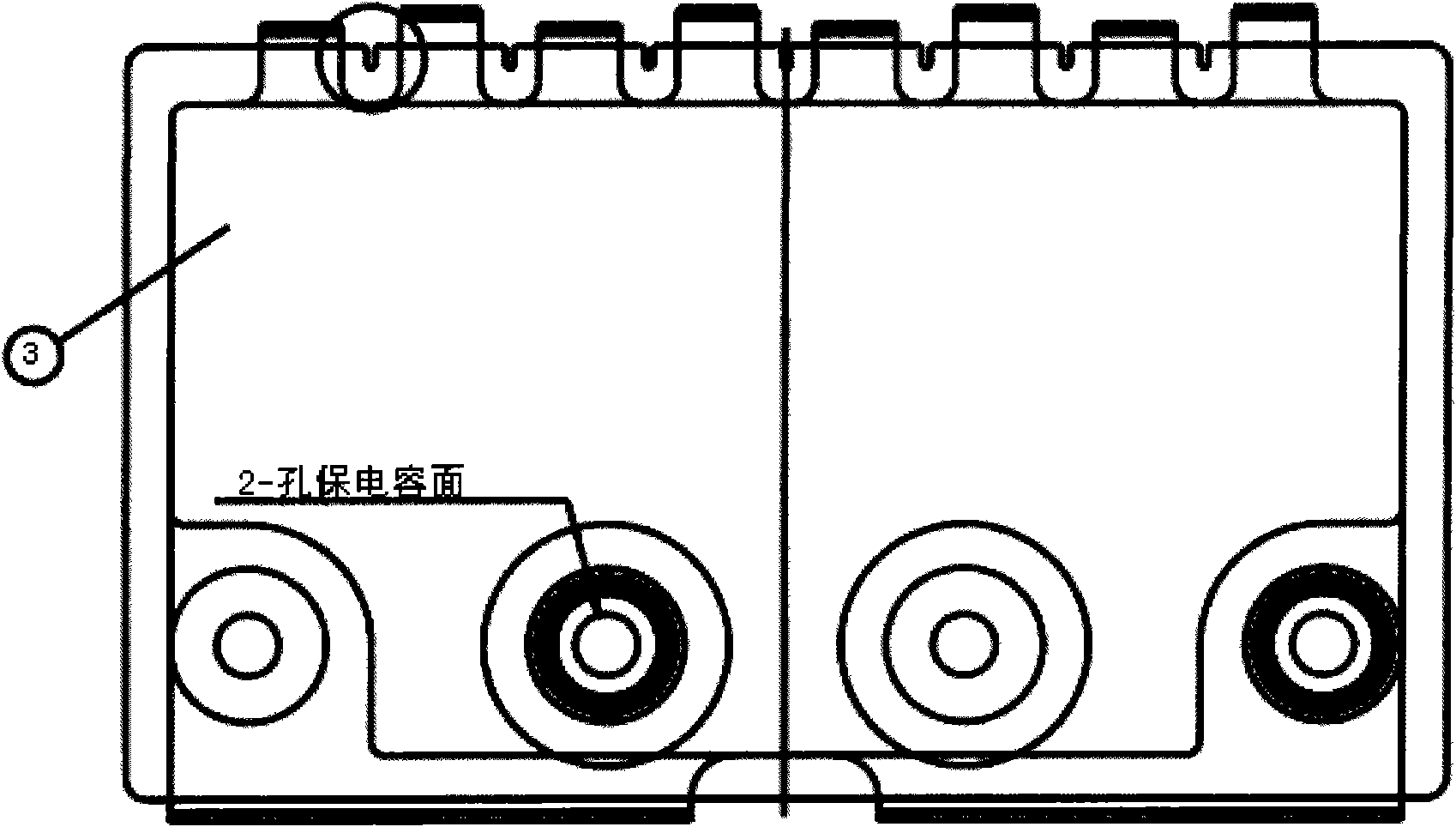

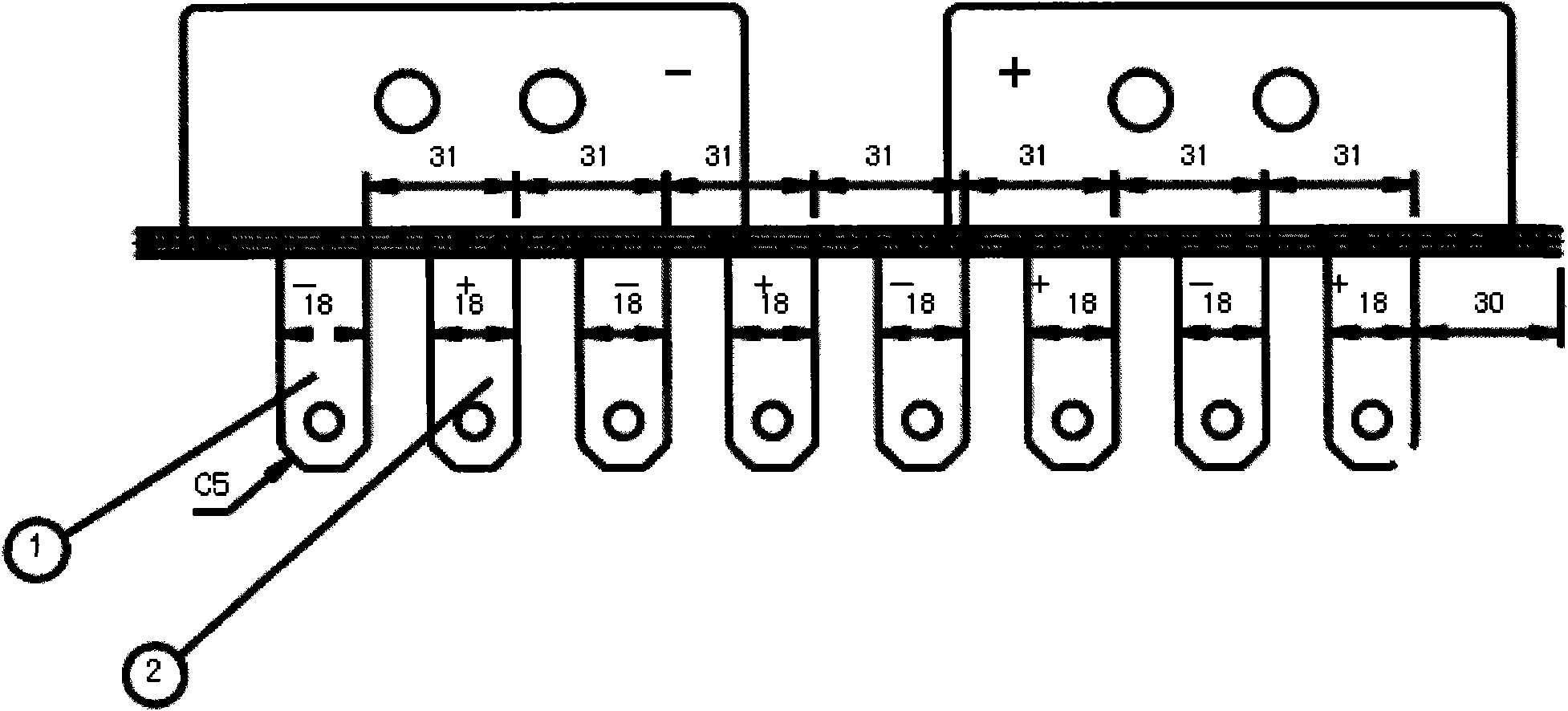

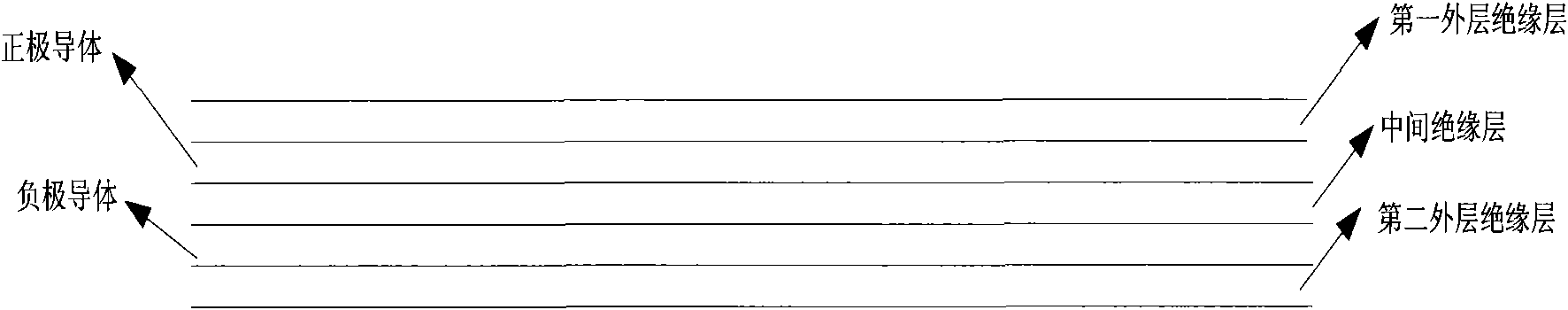

[0020] Such as Figures 1 to 3 As shown, the laminated busbar is characterized in that it includes a first outer insulating layer, a second outer insulating layer, a positive conductor, an intermediate insulating layer and a negative electrode conductor, wherein the first outer insulating layer and the first outer insulating layer are respectively arranged on both sides of the intermediate insulating layer For the second outer insulating layer, a positive electrode conductor is arranged between the first outer insulating layer and the intermediate insulating layer, and a negative electrode conductor is arranged between the second outer insulating layer and the intermediate insulating layer.

[0021] The laminated busbar is characterized in that the upper part of the laminated busbar is provided with positive and negative copper plates at intervals, and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com