Bus control method for pulse bag type dust cleaner and device

A bag filter and bus control technology, applied in chemical instruments and methods, separation methods, comprehensive factory control, etc., can solve the problems of remote centralized control, inability to change, inconvenient production, etc., to reduce workload and ensure reliability. , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

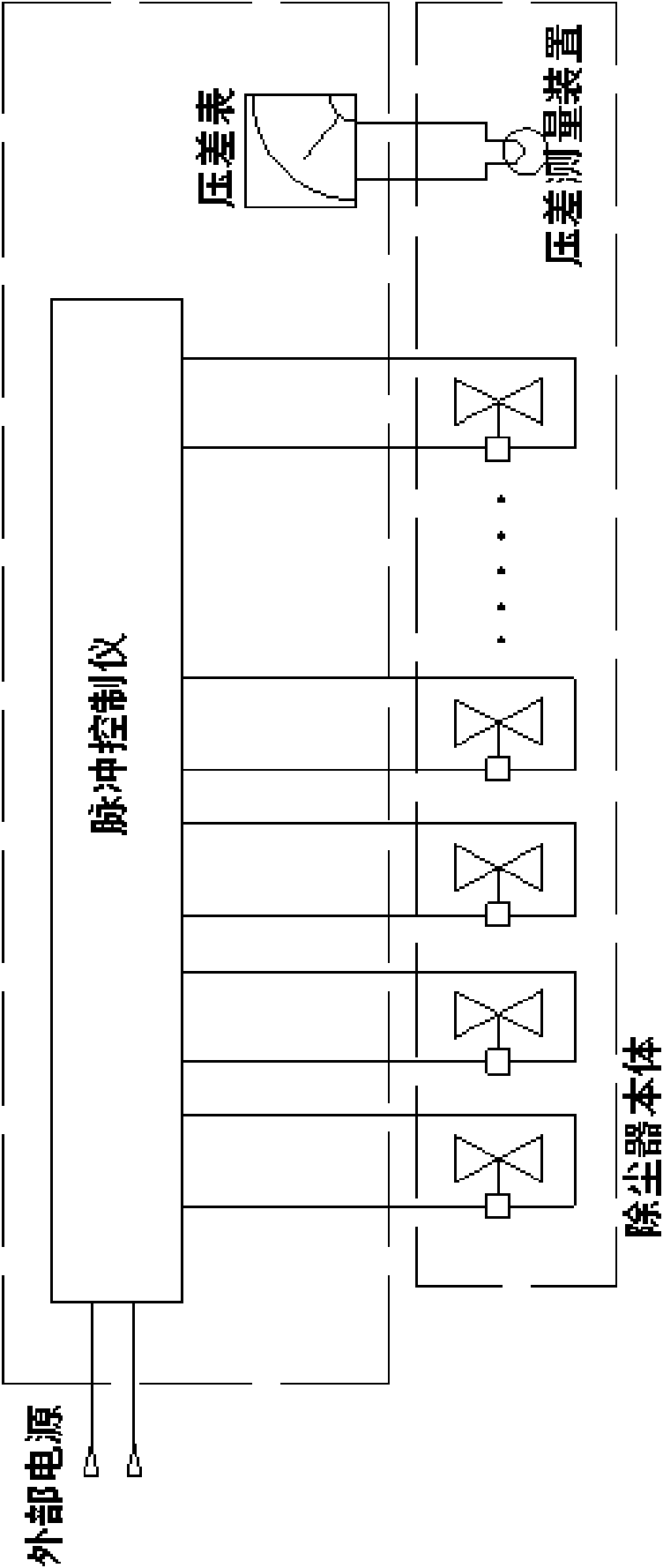

[0015] Embodiment of the present invention: The bus control method and device of the pulse bag filter of the present invention are improvements to the control method and control device in the prior art. The control principle of the dust collector in the prior art is as follows: figure 2 shown. from figure 2 It can be seen in the prior art that a pulse controller is used to control the pulse solenoid valve on the dust collector, and the differential pressure measuring device on the dust collector is connected with a differential pressure gauge, which has no connection with the pulse controller. The pulse solenoid valve on the dust collector cannot be automatically controlled according to the change of pressure difference, the degree of automation is low, and the pulse solenoid valve in the dust collector cannot be controlled in real time conveniently at any time.

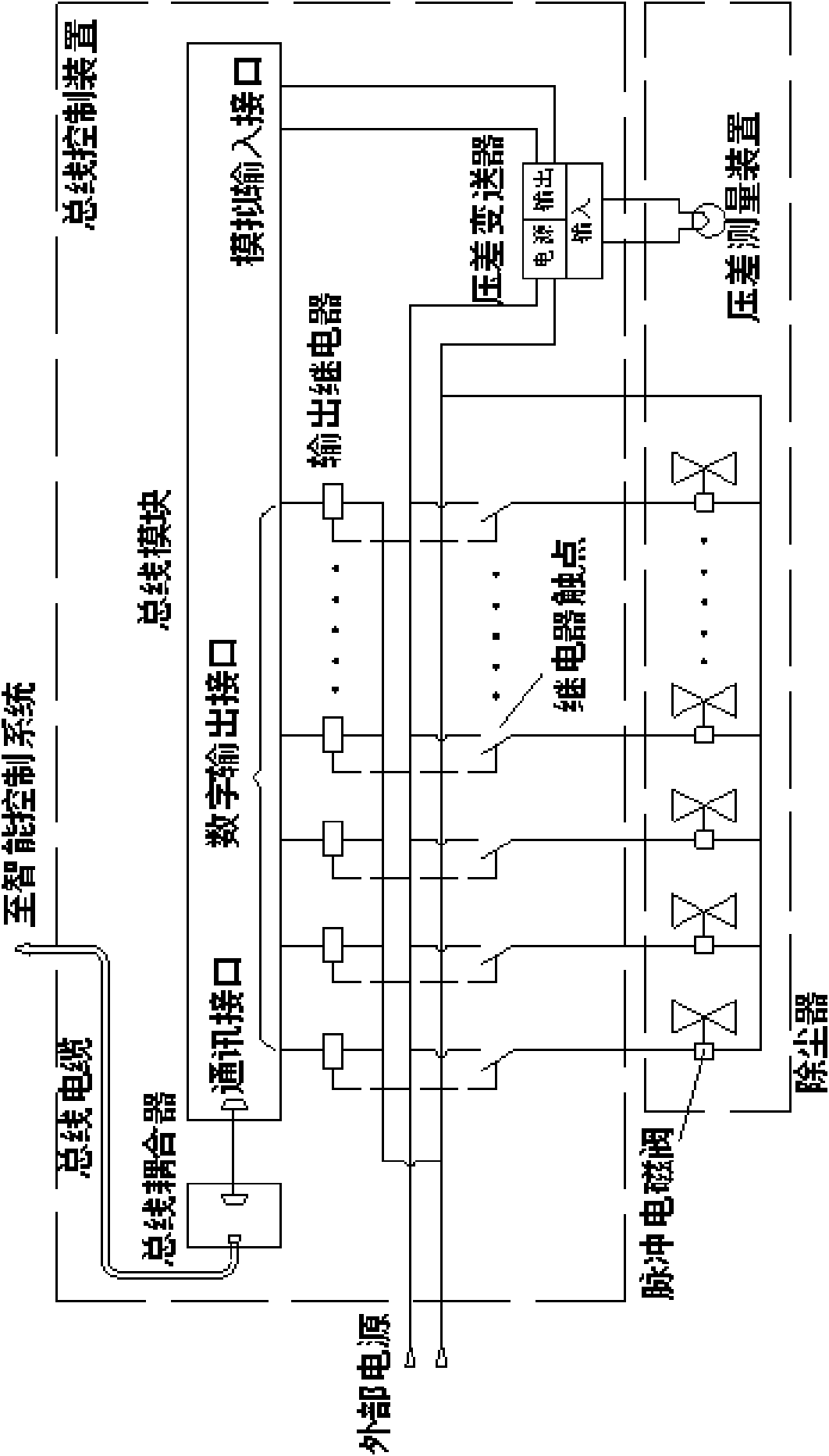

[0016] The bus control method of the pulse bag filter of the present invention is as follows: figure 1 as sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com