Multi-roll large-diameter thin-wall seamless pipe mill

A seamless pipe rolling mill and large-diameter technology, applied in metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve problems such as pipe breakage, low cost performance, and poor quality, and achieve a stable rolling process, High uniformity and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

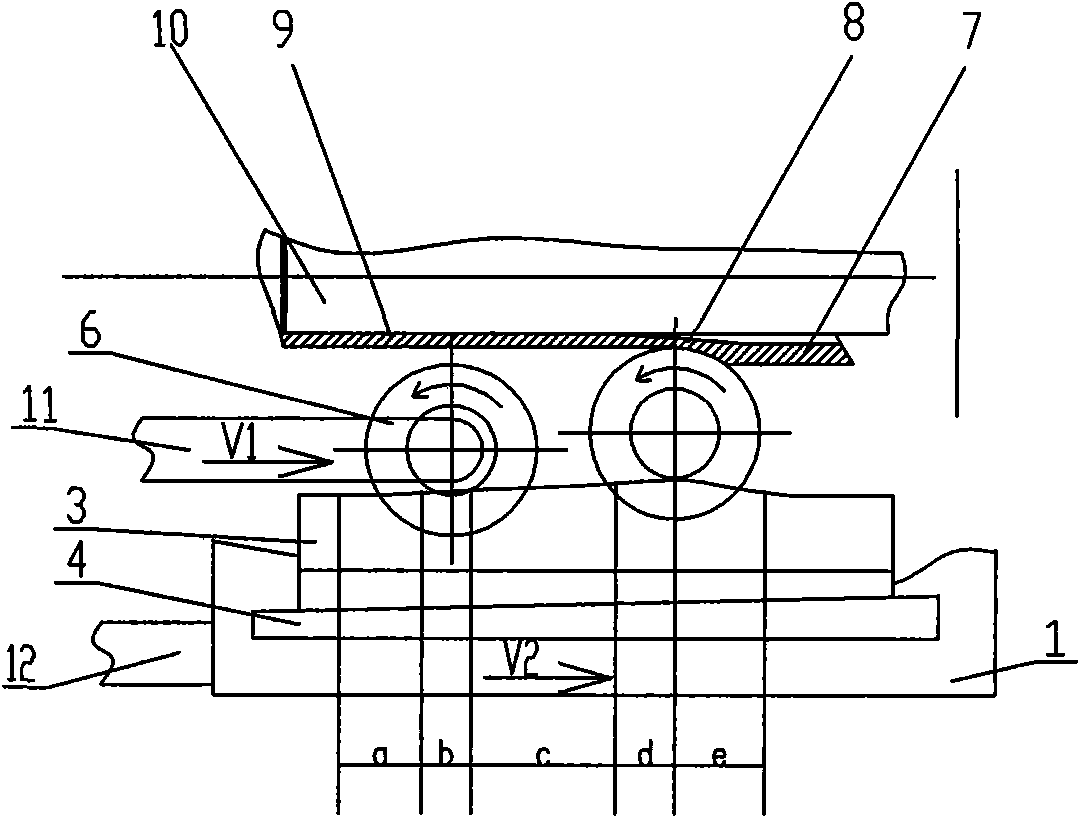

[0023] Such as figure 1 , 2 As shown, the present invention includes a main machine head, a seamless pipe clamping and feeding device, and a mandrel feeding recovery device; the main machine head includes a frame and a stand, and a rolling head is provided in the frame, and a rolling head drive is provided on the stand. mechanism, the rolling head in the frame can reciprocate relative to the machine base, the rolling head is concentrically arranged with the seamless pipe and mandrel 10, the driving mechanism of the rolling head is equipped with two-stage driving rods with different speeds that move synchronously, and the driving rods move along the rolling The head reciprocates in the axial direction; the rolling head is composed of a body and a roll group that are concentrically arranged and can move relative to the axis. The body includes a sleeve 1, a sector block 2, a slideway 3, and an adjustment wedge 4. At least four rolls 6 are formed; the guide frame 5 arranges at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com