LED light source with semiconductor heat dissipation device

A technology of LED light source and heat dissipation device, applied in the field of LED light source, can solve the problems of slow heat dissipation, unsatisfactory effect, large temperature influence, etc., and achieve the effects of convenient temperature, reduction of light decay, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

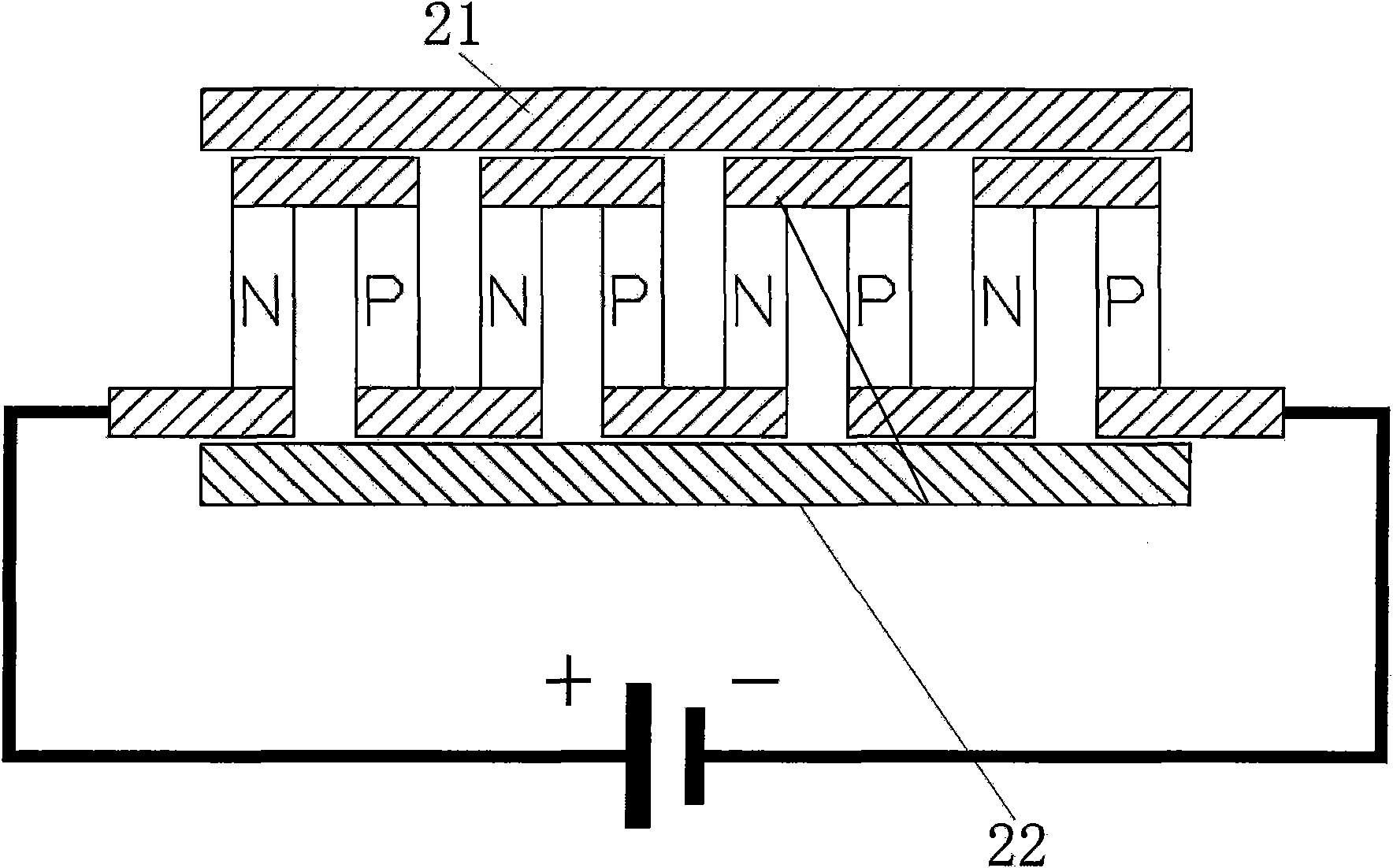

[0014] Semiconductor refrigeration principle such as figure 1 shown. When the semiconductor material is energized, a cold end 21 and a hot end 22 are generated on both sides of the semiconductor. The cold end will continuously absorb heat from the surrounding environment, and transfer the absorbed heat to the hot end through the thermal movement of molecules. The temperature difference between the cold and hot ends Up to tens of degrees.

[0015] This invention utilizes this feature of semiconductor refrigeration to closely connect the cold end and the heat concentration point on the back of the LED high-power light source, so that the semiconductor refrigeration sheet absorbs the heat generated by the LED, and conducts the absorbed heat to its hot end, and then , and then dissipate into the environment.

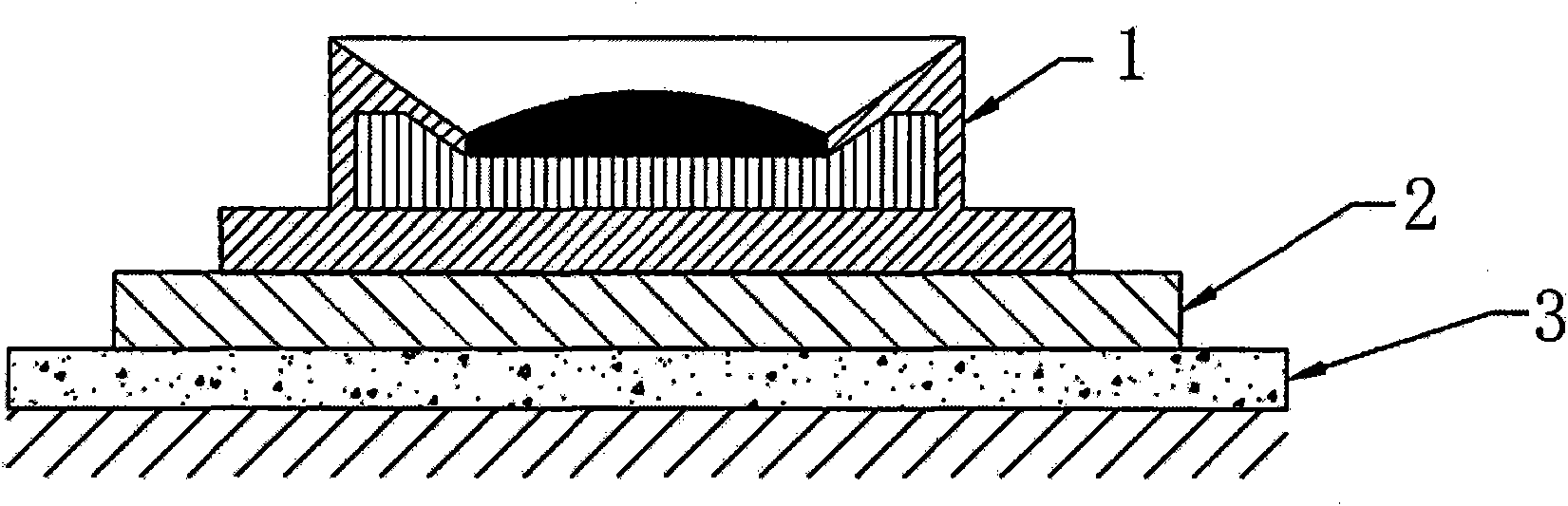

[0016] In a preferred embodiment of the present invention, a heat sink can also be connected to the hot end of the semiconductor refrigerating sheet, and the heat of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com