Oil filter cover structure

A technology of oil filter and cover structure, which is applied in the installation/connection of lubricant purification device, lubricating parts, pressure lubricant, etc., which can solve the problems of increasing engine operating vibration, decreasing the stability of crankshaft operation, and shortening the use of crankshaft Life and other issues, to achieve the effect of prolonging the service life, easy implementation, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

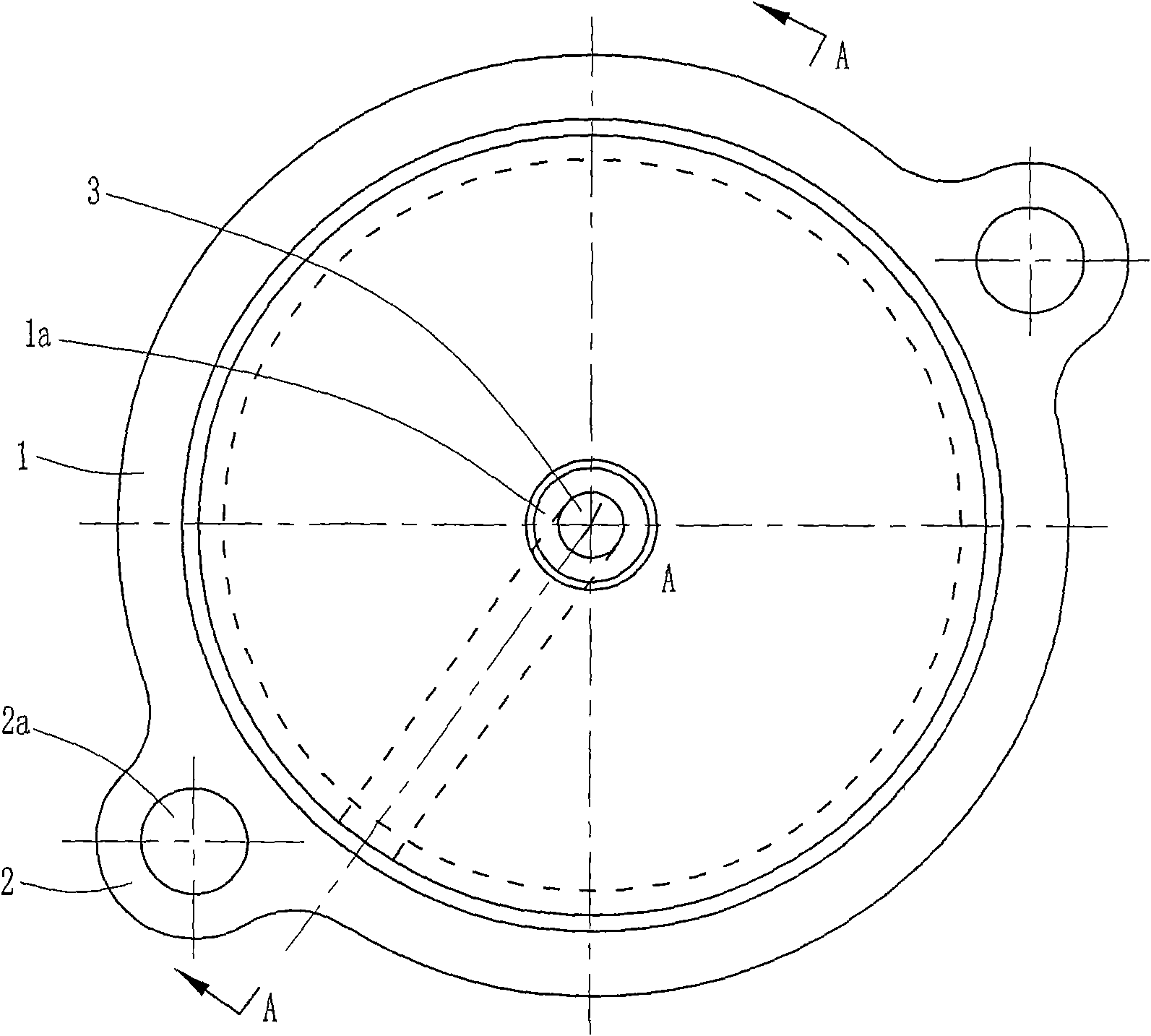

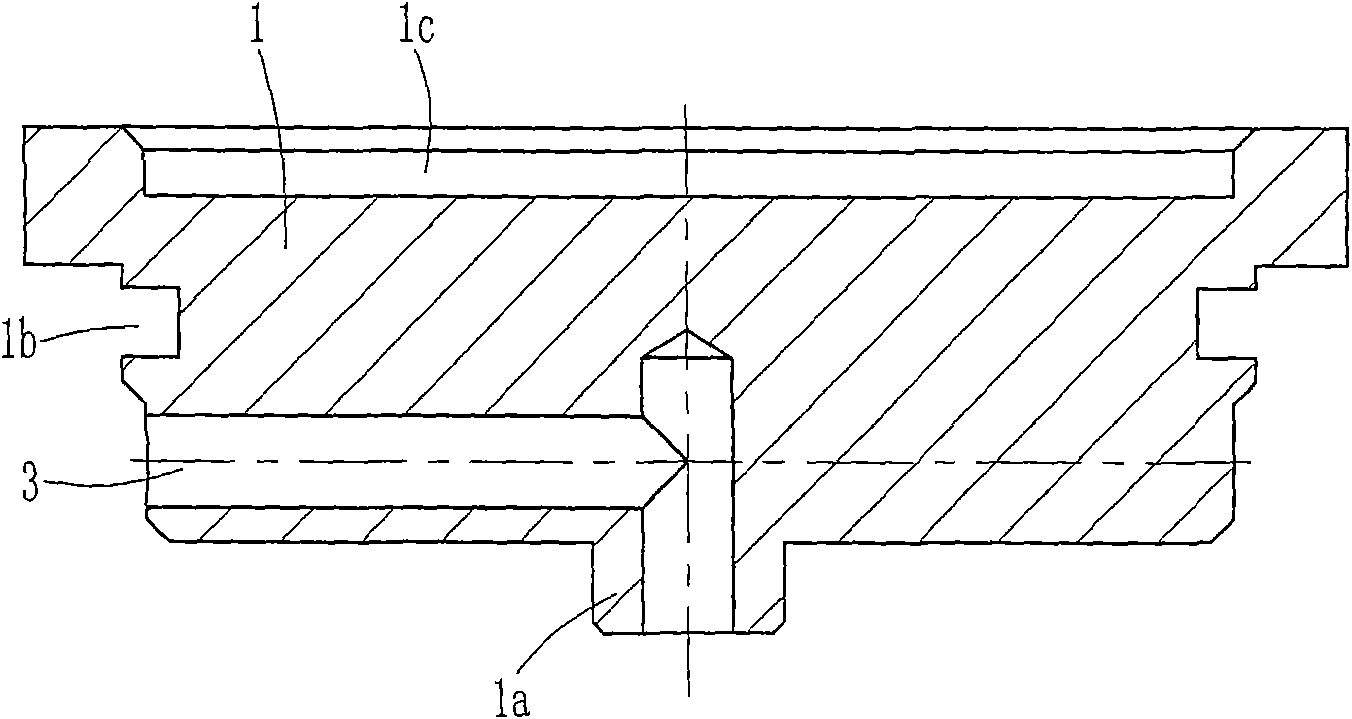

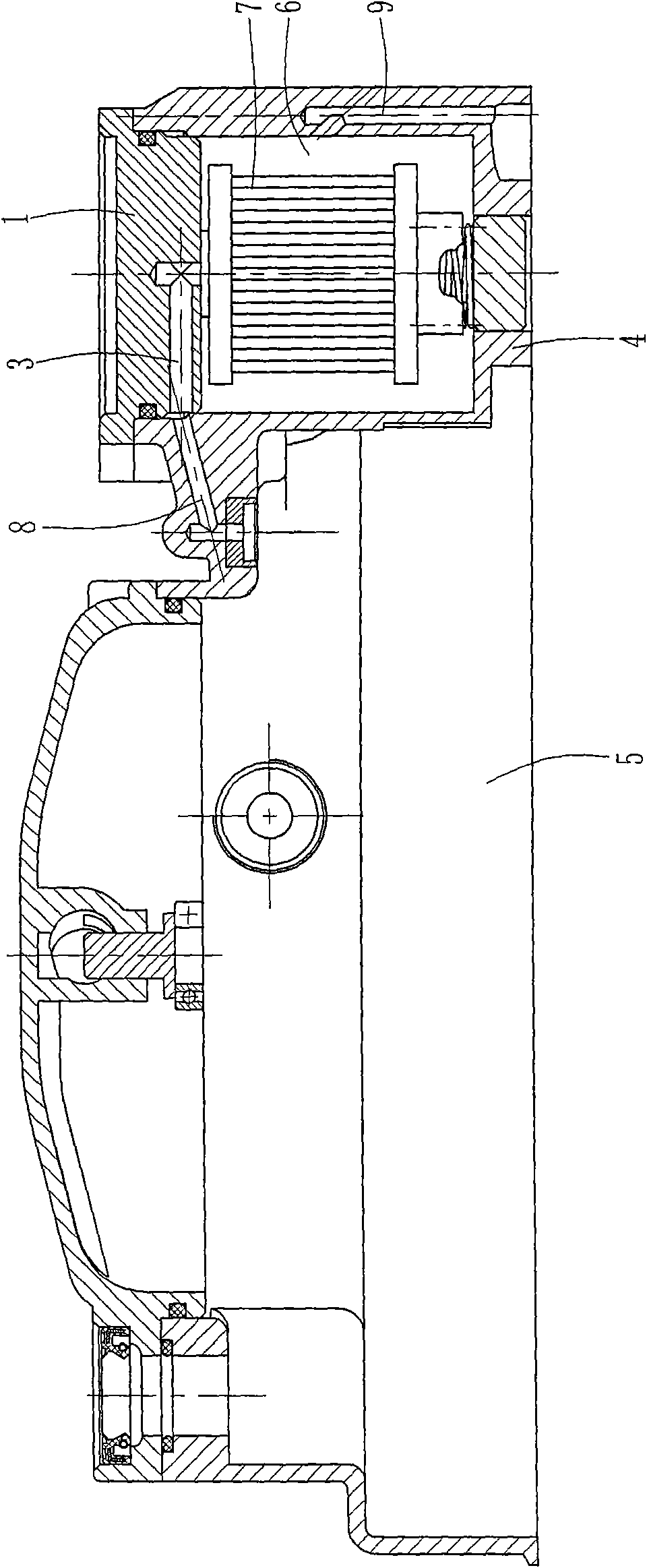

[0017] Such as figure 1 , figure 2 As shown, an oil filter cover structure has a cover body 1, the cover body 1 is a stepped cylindrical structure with a large upper part and a smaller lower part, and a circular sinking groove 1c is opened on the top surface of the cover body 1. The sunken groove 1c plays a decorative role, and the center of the bottom surface of the cover body 1 is integrally formed with a circular boss 1a. The stage of the cover body 1 is relatively short, and the stage of the step-off stage is long. Two lugs 2 are symmetrically arranged on the outer circumference of the cover body 1. The lugs 2 and the cover body 1 are integral structures, and each The lug 2 is provided with an installation through hole 2a. An annular groove 1b is opened on the upper peripheral surface of the cover body 1 when it is lowered from the stage, for the O-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com