Pile machine

A technology of pile driver and lifting platform, which is applied to sheet pile walls, lifting devices, safety devices of lifting equipment, etc., can solve the problems of the tilting of the 3' center of gravity of the lifting platform, the tilting of the lifting platform, the danger of workers, etc. The effect of short response time and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a pile driver for engineering machinery. The deviation correction device of the pile driver can conveniently and quickly control the swing amplitude of the lifting platform within an appropriate range, so that the lifting platform is basically in a horizontal state.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

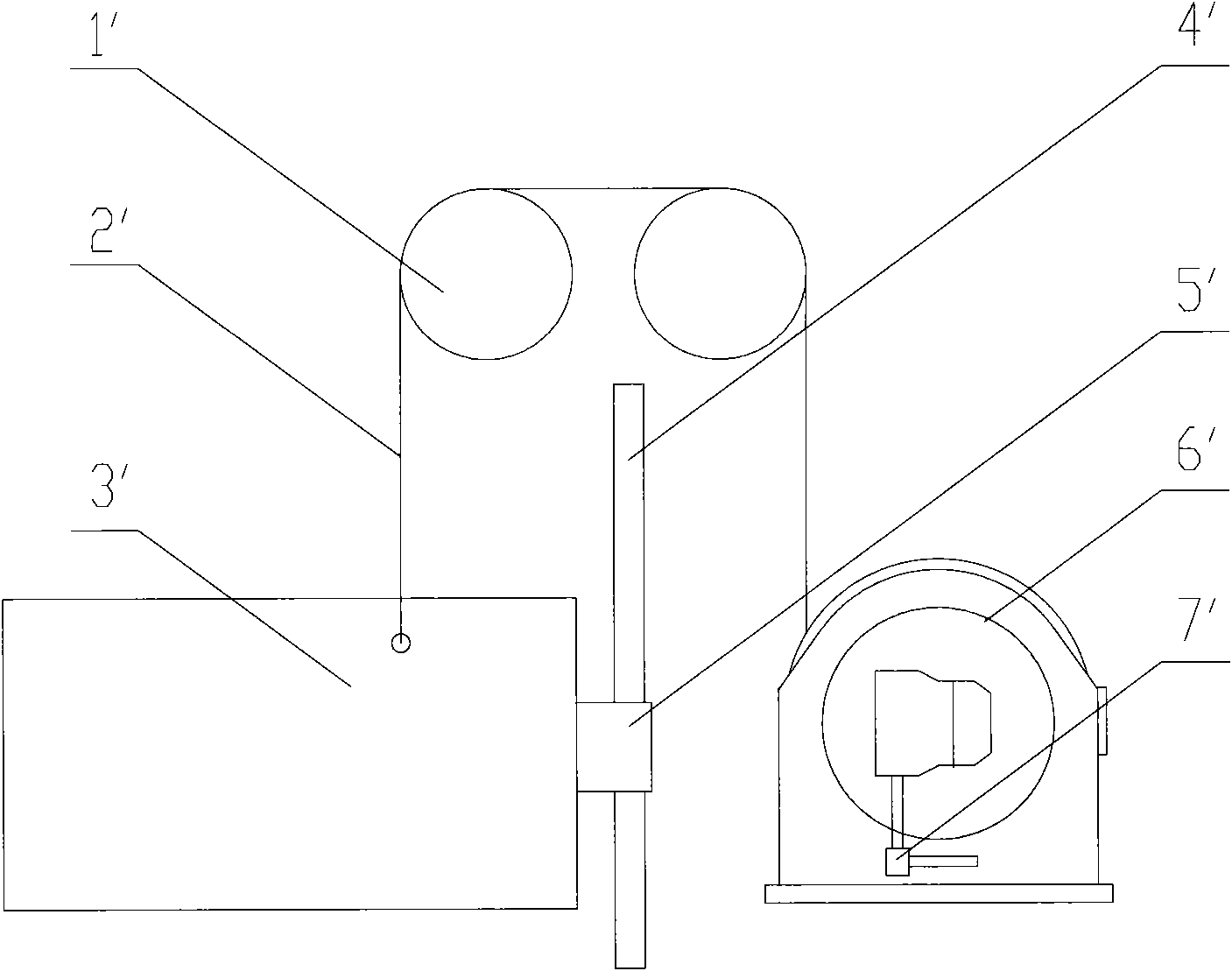

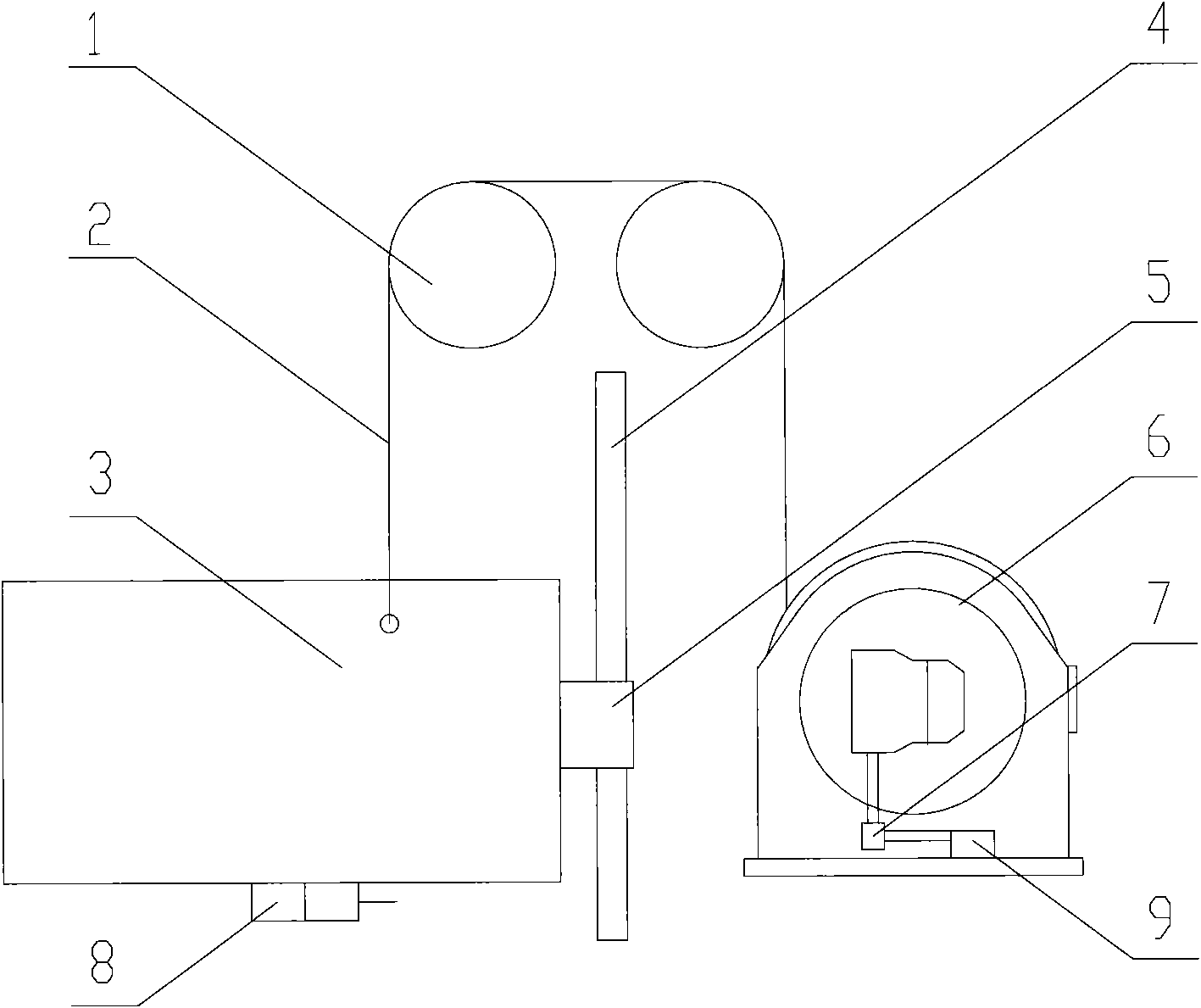

[0027] Please refer to figure 2 , figure 2 It is a structural schematic diagram of a specific embodiment of the pile driver provided by the present invention.

[0028] In a specific embodiment, the pile driver provided by the present invention includes at least two steel wire ropes 2, and one end of each steel wire rope 2 is respectively connected to the suspension rings on the two side walls of the lifting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com