Impact wrench

An impact wrench, non-impact technology, applied in the field of impact wrench, can solve problems such as tilt danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

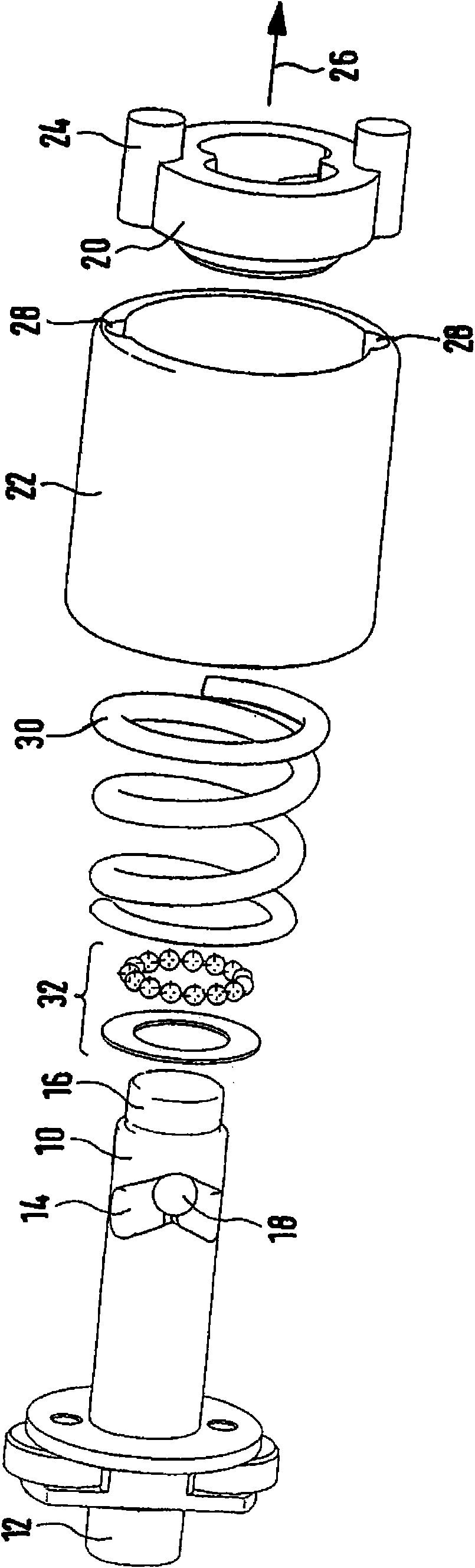

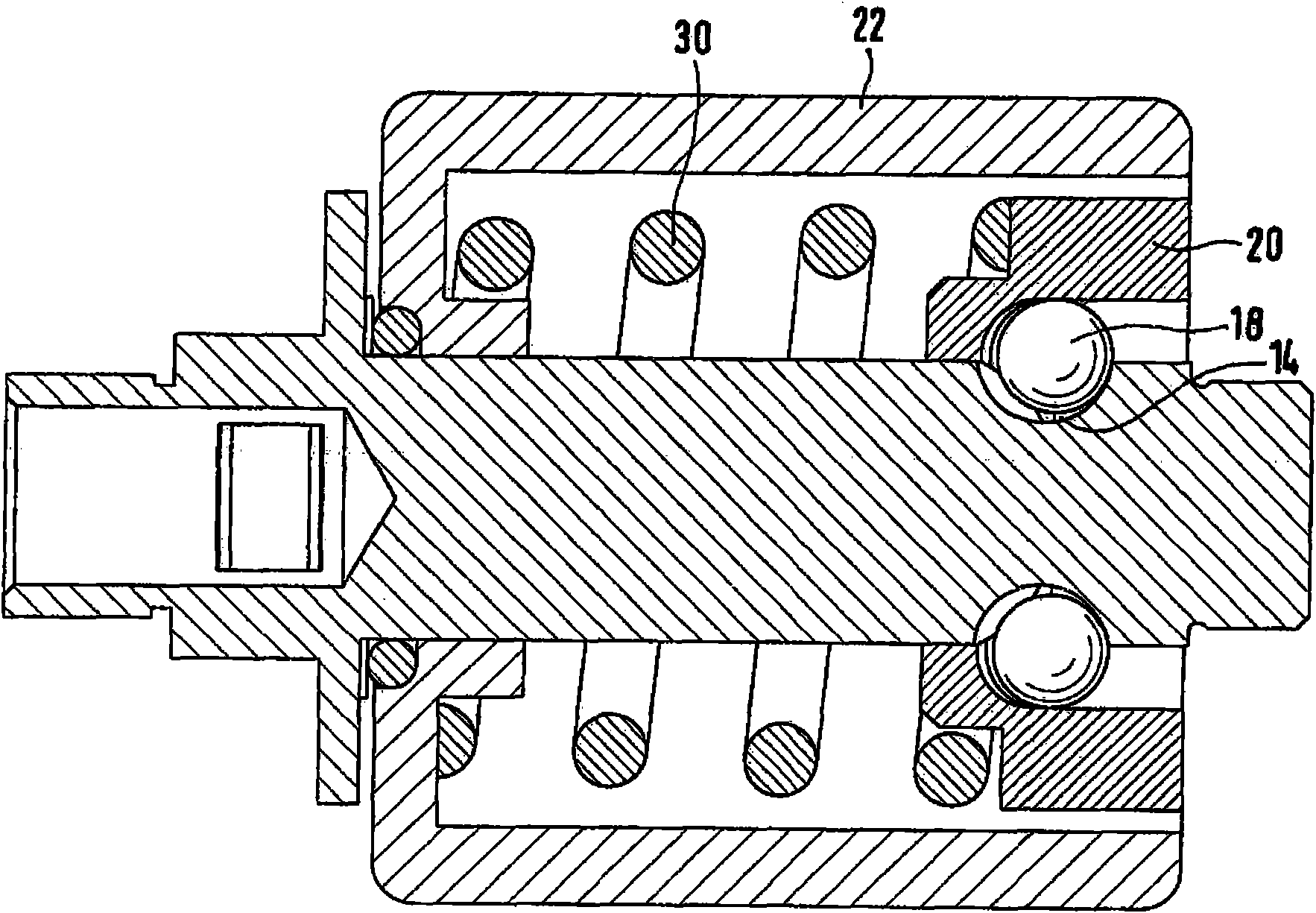

[0031] figure 1 Shown is an impact device according to the invention having a drive shaft 10 comprising a drive-side end 12 by means of which the drive shaft 10 can communicate with a drive motor (not shown), in particular via a transmission. ) coupling. A V-shaped groove 14 is provided on the transmission shaft 10 , wherein the apex of the V-shaped groove points toward the output-side end 16 of the transmission shaft 10 . Balls 18 are respectively introduced into V-shaped grooves 14, wherein two grooves 14 are arranged diametrically opposite each other on the transmission shaft 10, wherein corresponding running surfaces (not shown) for receiving balls 18 are provided in control element 20 out). Via the groove 14 and the ball guide 18 , the control part 20 is movable relative to the drive shaft 10 in the region of the groove 14 and in particular can perform axial and rotational oscillating movements. The percussion device also includes a rotating mass 22 , wherein the revol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com