Orderly glue stock kneader

A kneader and rubber technology, which is applied in the direction of mixers, mixers with rotating stirring devices, dissolution, etc., can solve problems such as short service life, chains affecting power transmission, and poor sealing performance, so as to improve service life and seal Good effect, easy to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the drawings and embodiments.

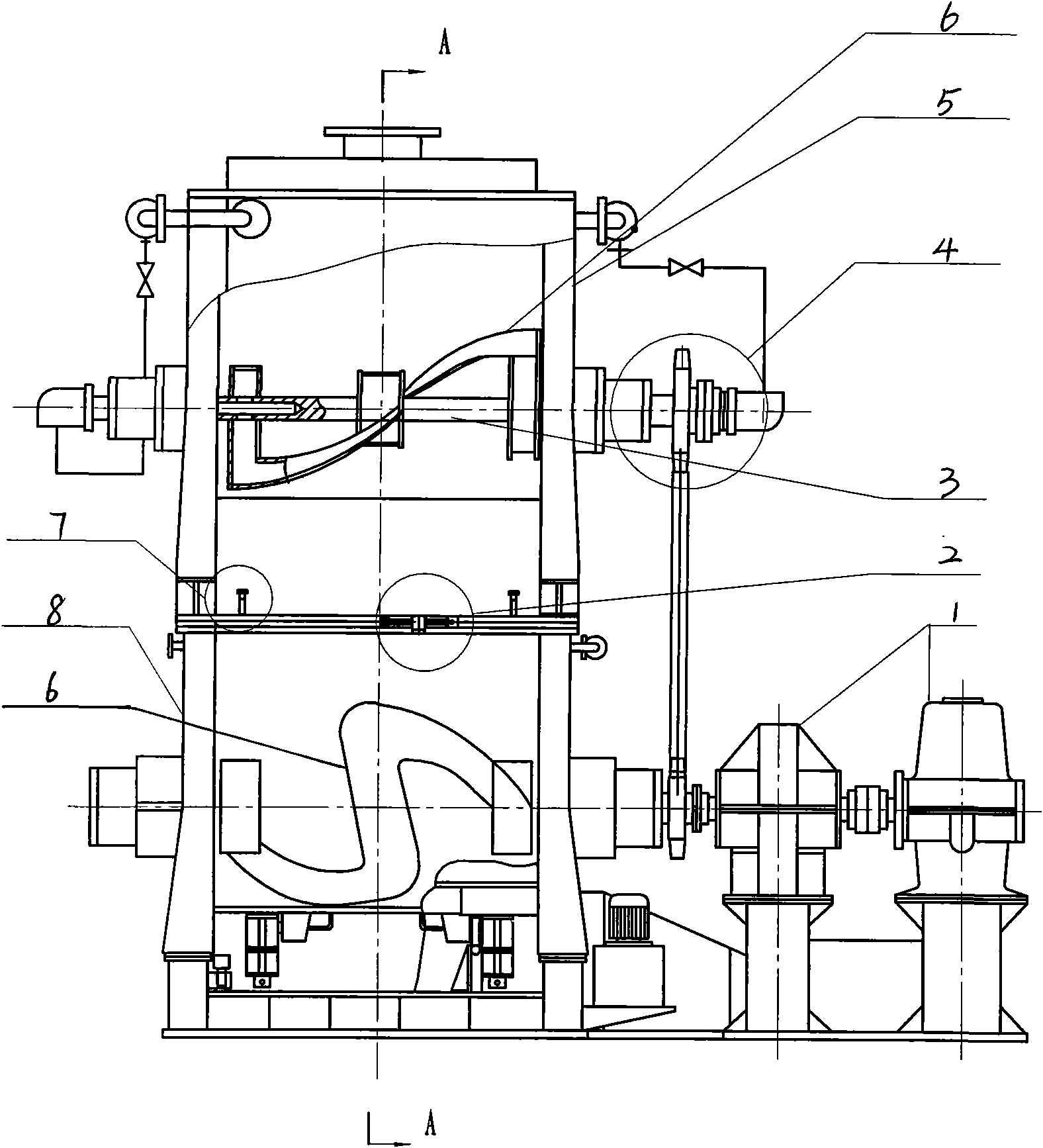

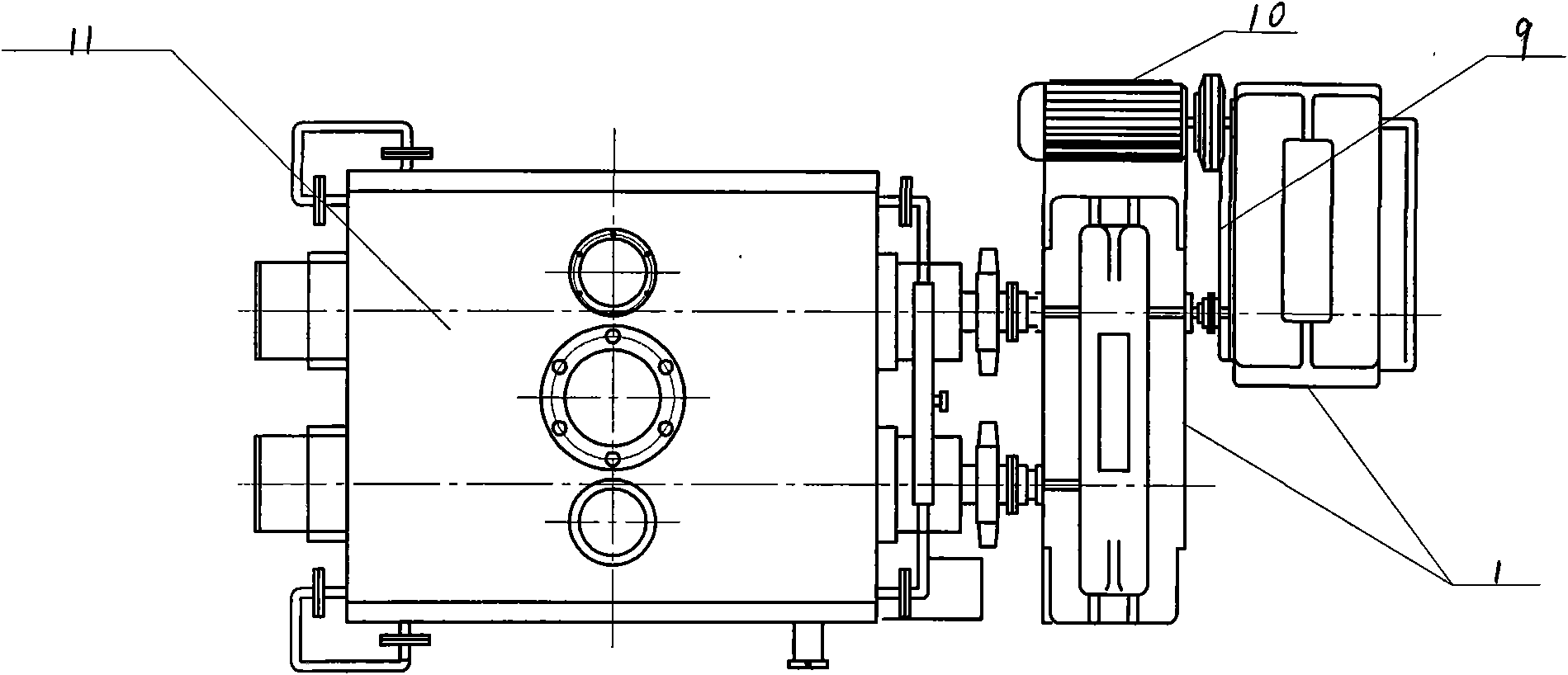

[0046] Such as figure 1 , 2 3, this example includes a transmission part 9 and a pot body part 11. The pot body part 11 is composed of an upper pot body 5 with a stirring knife 6 inside and a lower pot body 8 with a stirring knife 6 inside. Layer structure.

[0047] Among them, the upper pot body 5 has two parallel-installed first divided pot bodies 5-1 (powder divided pot bodies) and second divided pot bodies 5-2 (aggregate divided pot bodies). The first divided pot body 5-1, the second divided pot body 5-2 and the lower pot body 8 are equipped with a stirring knife 6 through a stirring knife shaft 3, respectively. An upper discharge system 12 is provided below the bottom discharge opening of the first divided pot body 5-1 and the second divided pot body 5-2, respectively, and the first divided pot body 5-1 and the second divided pot body 5-2 are discharged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com