Touch-control sensing structure for liquid crystal display

A liquid crystal display, touch sensing technology, applied in static indicators, instruments, electric solid devices, etc., can solve the problems of decreased light transmittance, inconsistent with the lightness, thinness and shortness of the display, and increased reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

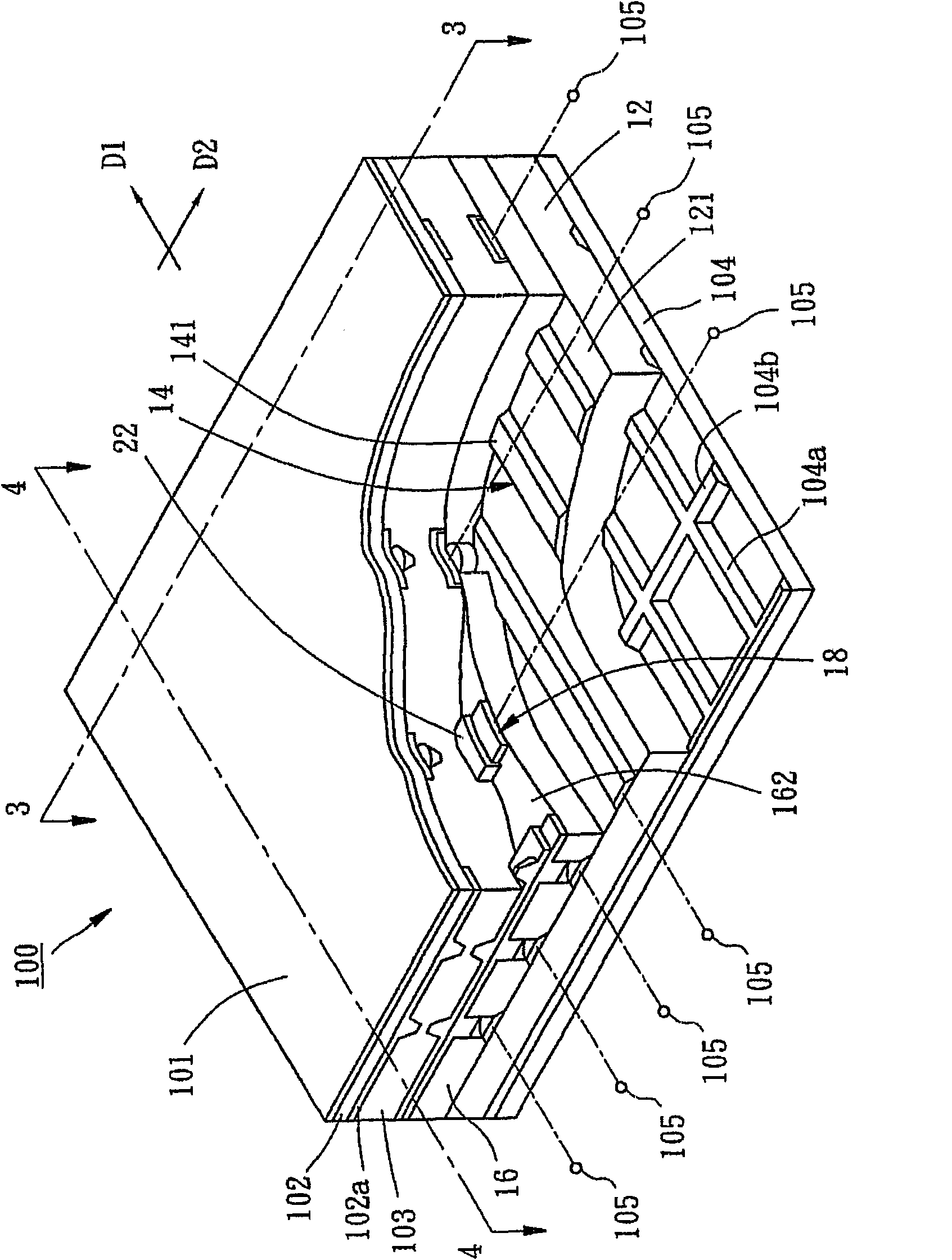

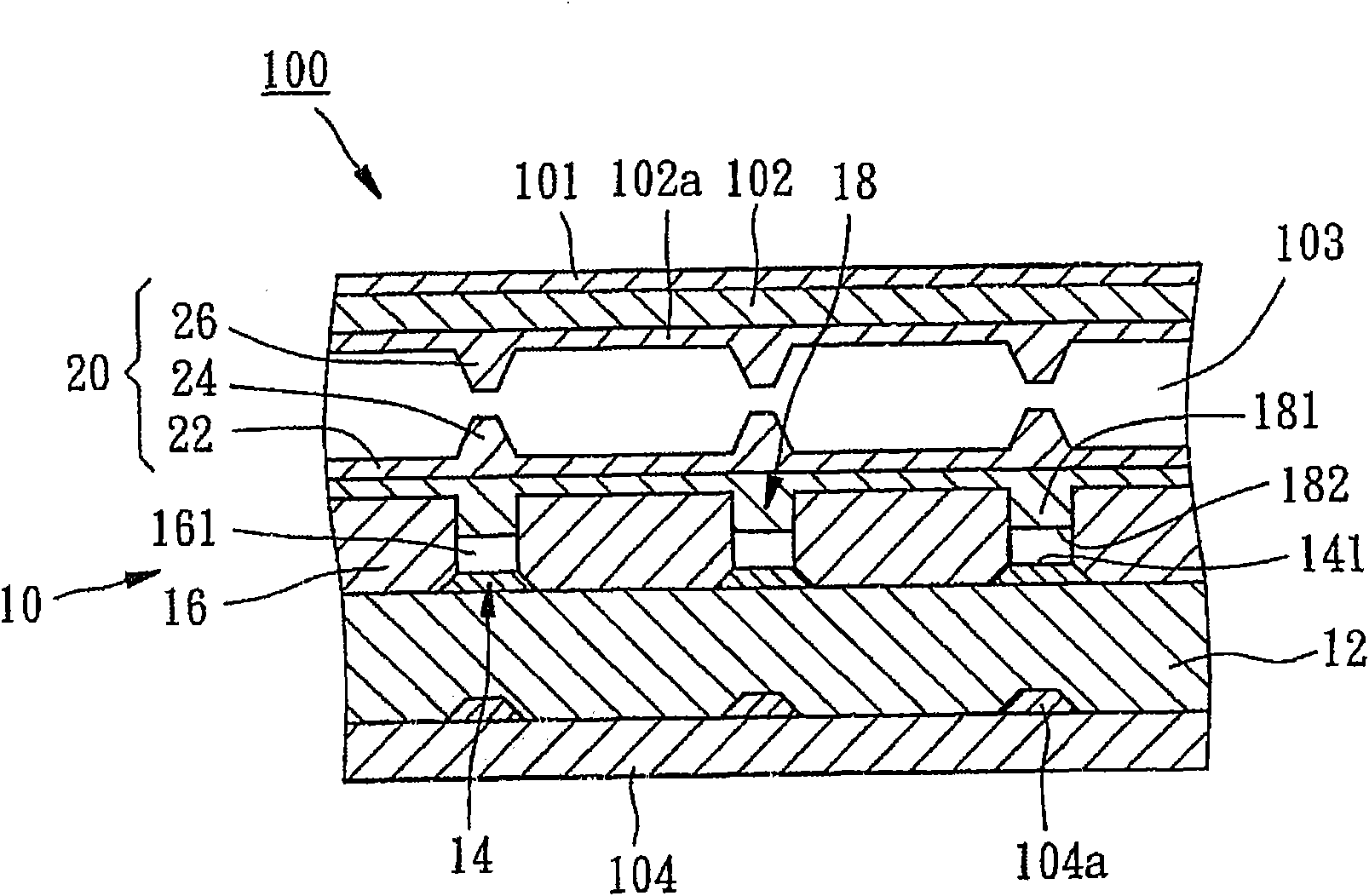

[0039] Figure 2 to Figure 4 Disclosed is a liquid crystal display 100 comprising a touch sensing structure 10 according to a preferred embodiment of the present invention. The structure of the liquid crystal display 100 includes an upper substrate 101, a color filter layer 102, a liquid crystal layer 103 and a bottom substrate from top to bottom. The substrate 104, wherein the color filter layer 102 includes a plurality of red, green and blue filter units (not shown), and a filter unit for isolating these red, green and blue filter units to avoid The black matrix 102a in which the filter units interfere with each other, the lower substrate 104 is a thin film transistor array substrate, including a plurality of data lines 104a and a plurality of scanning lines 104b interlaced with each other. Since the above components belong to the existing structure, here I won't go into details.

[0040] The touch sensing structure 10 of this embodiment includes a first insulating layer 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com