Minitype F-P reflective index sensor of full optical fiber ring-type reflecting surface structure

A technology of a refractive index sensor and a reflective surface, applied in the field of optical sensing, can solve the problems that the contrast ratio of the Fibonacci cavity is easily affected by the light source, the long-period fiber grating is greatly affected by the bending, and the bare fiber is easily polluted, and achieves high reliability. , small size, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

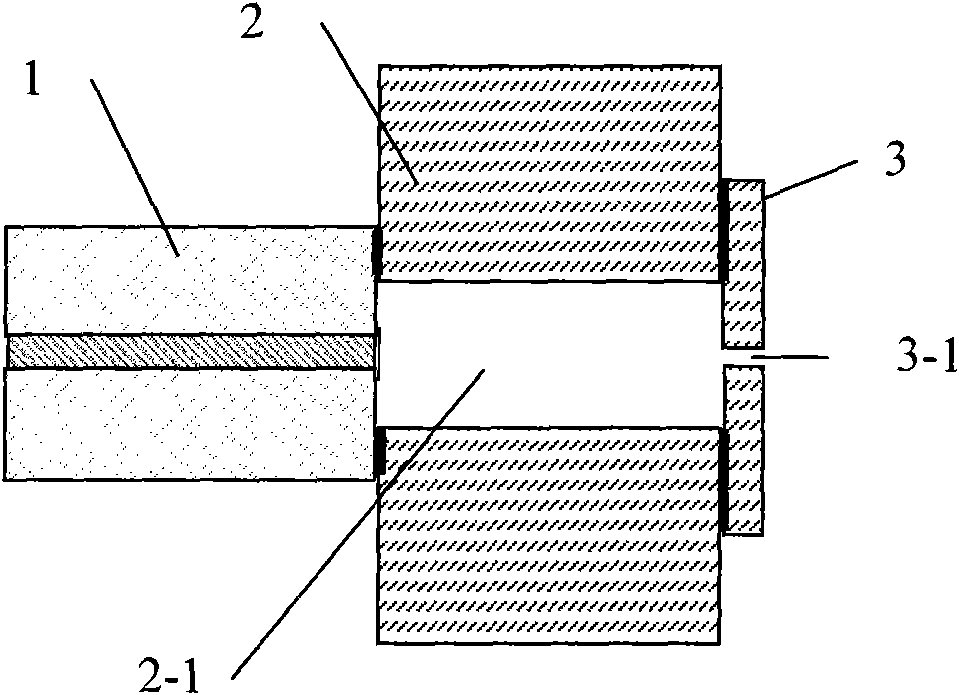

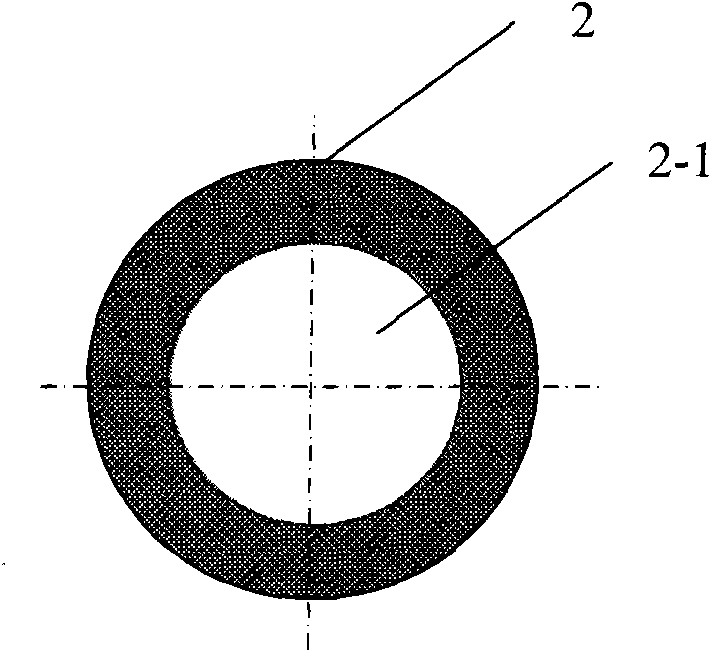

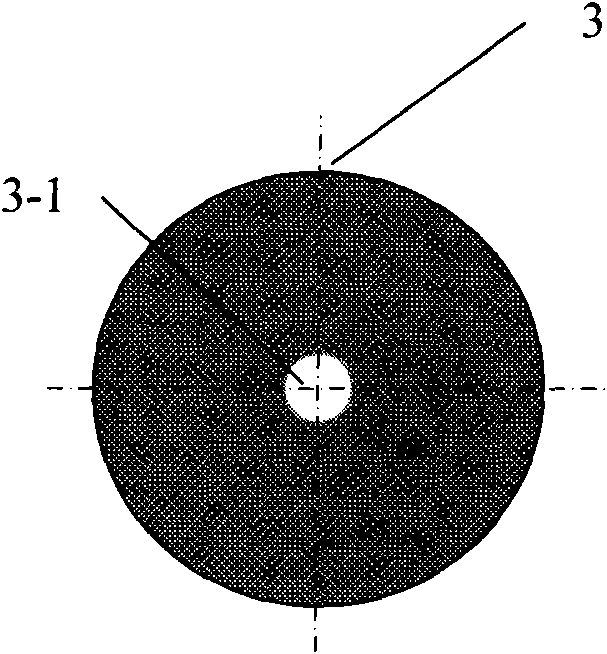

[0020] see figure 1 , shown in the figure is the sensor structure of the present invention, which is composed of ordinary single-mode optical fiber 1, large-diameter hollow-core optical fiber 2 and optical fiber 3 with a through hole in the center, ordinary single-mode optical fiber 1, large-core diameter hollow-core optical fiber 2. The optical fiber 3 with a through hole in the center is welded and fixed in sequence, and the hollow core fiber 2 with a large core diameter communicates with the optical fiber 3 with a through hole in the center;

[0021] The two ports of the core (that is, the F-P cavity) of the large-core hollow-core fiber 2 are respectively closed by the ordinary single-mode fiber 1 and the optical fiber 3 with a through hole in the center, and the inside of the core of the large-core hollow-core fiber 2 (2 in the figure -1 place) can only communicate with the external environment through the fiber core (3-1 place among the figures) of the optical fiber 3 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com