Clamp for rail fatigue experiment acted by bending moment

A technology of fatigue experiment and fixture, which is applied in the direction of applying stable bending force to test the strength of materials, measuring devices, instruments, etc. It can solve the problems of providing, not being able to simulate the working conditions of rail materials, difficult rails, etc., and achieve simple test operation, Easy replacement of the loading head, high correlation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

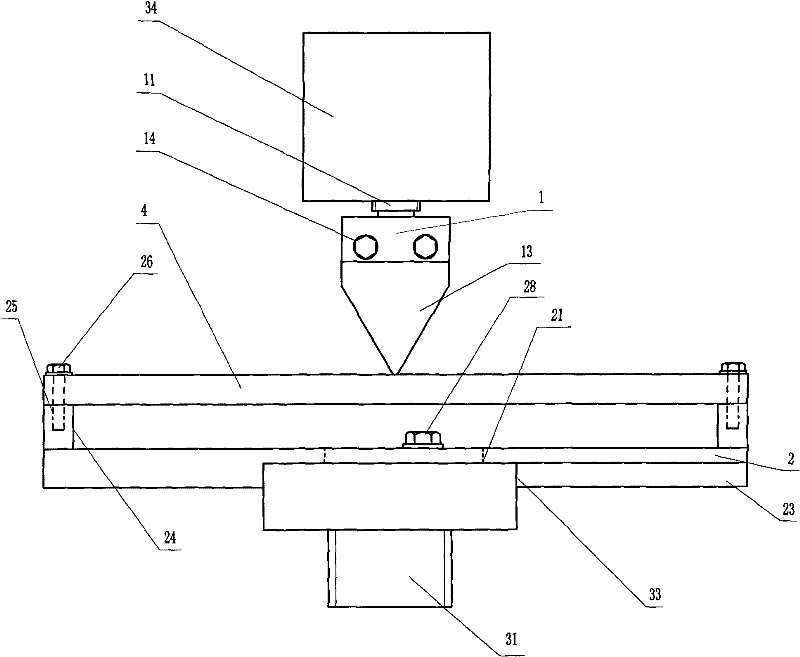

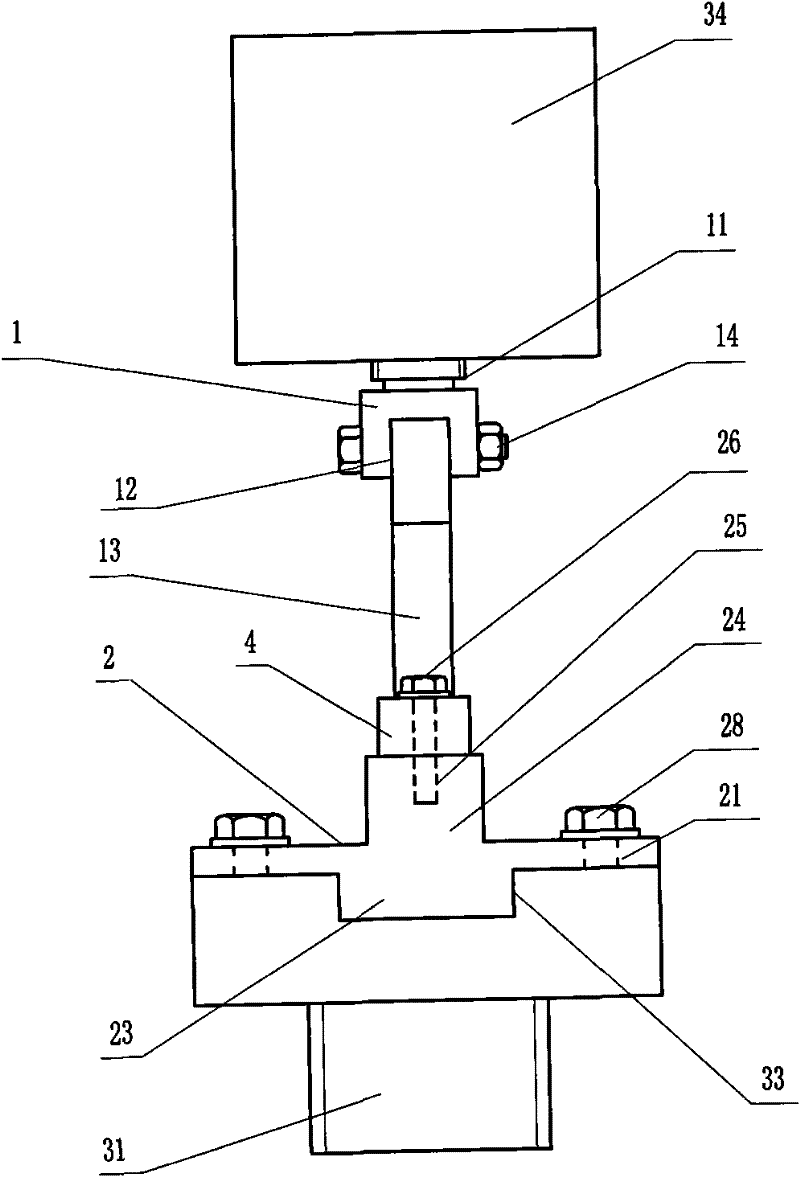

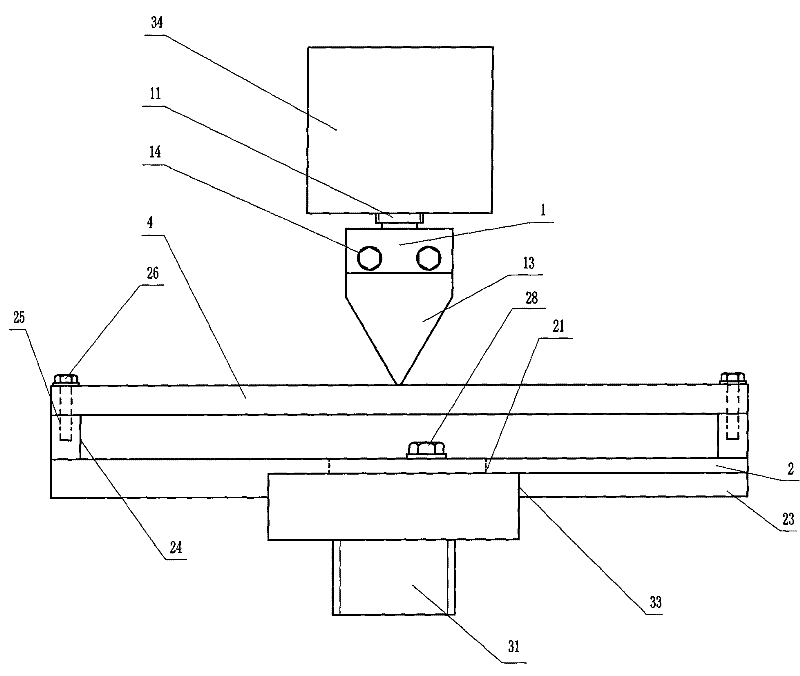

[0019] figure 1 , figure 2 As shown, a specific embodiment of the present invention is: a rail fatigue test fixture under the action of bending moment, including an upper fixture 1 and a lower fixture 2 . The upper part of the upper fixture 1 is the screw rod 11 threadedly connected with the experimental machine force sensor 34, and the lower part is a rectangular slot 12 with the opening downward. The flat top of the triangular loading head 13 is inserted into the rectangular slot, and passes through the rectangular slot 12 and the opening of the loading head 13. The screw 14 connects the upper fixture 1 with the loading head 13; the lower end of the loading head 13 is arc-shaped with a curvature radius of 1-10 mm. The lower fixture 2 is a rectangular platform. The lower fixture 2 is provided with a strip mounting hole 21 corresponding to the threaded mounting hole of the hydraulic cylinder 31 of the experimental machine. The bottom of the lower fixture 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com