Fixing force transfer bracket for thermodynamic pipe in thermodynamic shield tunnel

A technology of thermal pipelines and force-transmitting brackets, which is used in pipeline brackets, pipes/pipe joints/fittings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

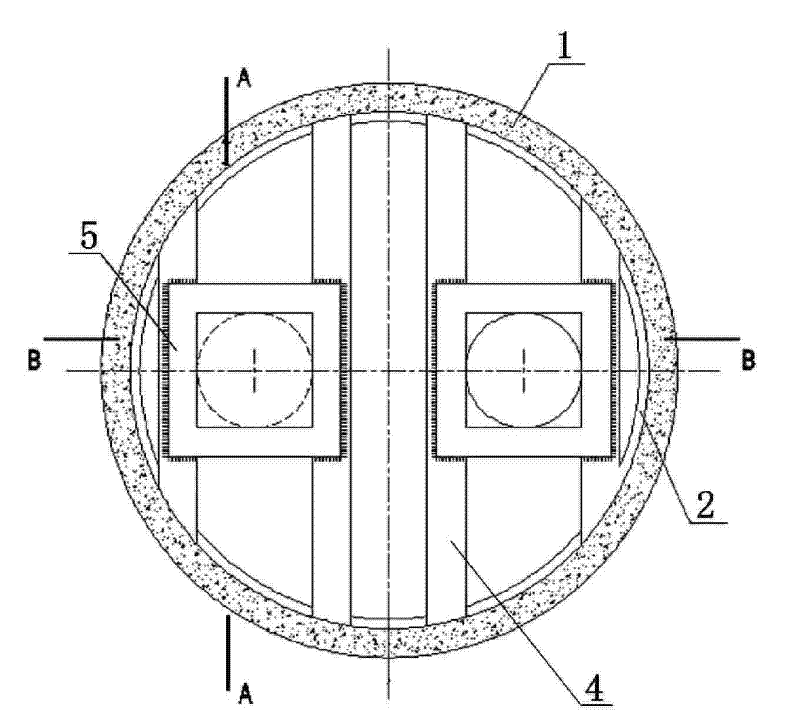

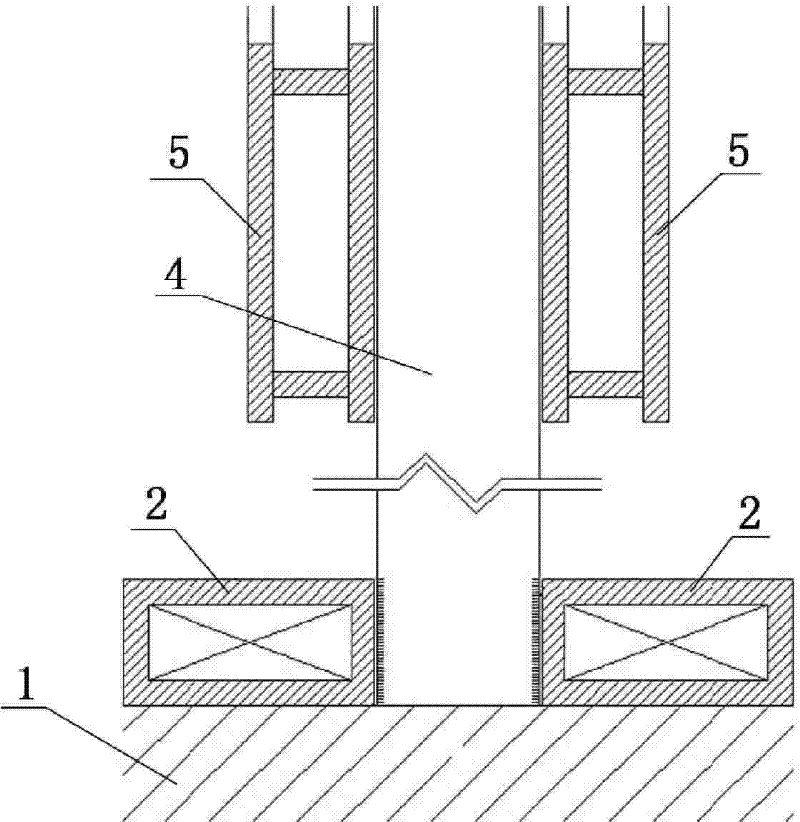

[0020] Examples see Figure 1-3 As shown, the heat pipe fixed force transmission bracket of this thermal shield tunnel is distributed on the inner wall of the tunnel at intervals. The tunnel is composed of 6 prefabricated segments 1, and the length is 1200mm. The heat pipe fixed force transmission support Including ring beam 2, fixing piece 3, upright column 4 and force frame 5, the inner wall of the tunnel is fixed by double arched fixing piece 3 with two circles of ring beam 2, and two or four upright columns 4 are fixed between the two circles of ring beams , the two ends of each column 4 are supported on both sides of the inner wall of the tunnel, and the front and rear sides of every two columns are respectively connected with a stress frame 5 for passing through the thermal pipeline.

[0021] The size of the steel column is 400X400X20 (mm). The material of the steel column is Q235 steel.

[0022] see Figure 3-4 As shown, the force frame 5 is composed of two square fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com