Phosphorus removing agent and preparation method and phosphorus removing method thereof

A technology of phosphorus removal agent and silicon additive, which is applied in the field of sewage treatment and environmental protection engineering, and can solve the problems of secondary pollution and large amount of lime sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

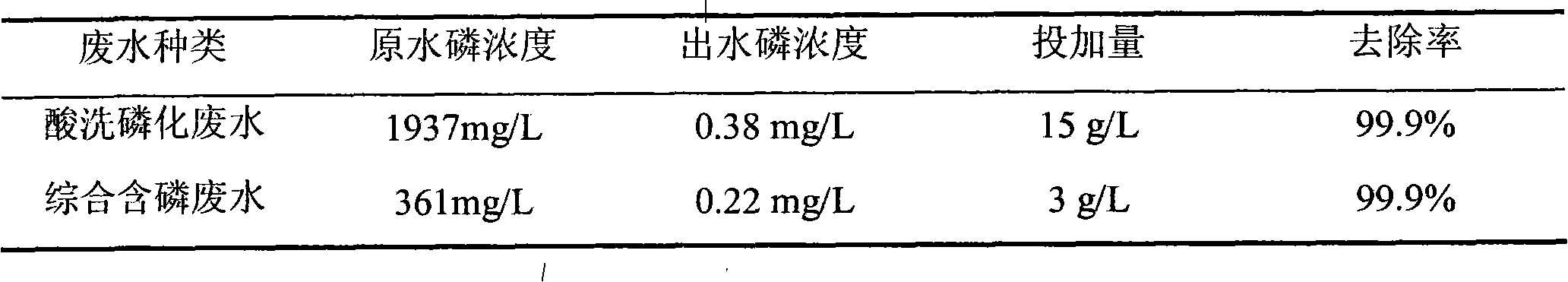

[0022] Embodiment 1: get the CaCl of 50% (mass percentage, the same below) 2 , 20% AlCl 3 , 10% FeCl 2 , 10% SiO 2 , through the sol-gel reaction, and then the precipitate after the reaction was dried and sieved to obtain the phosphorus removal agent (named LB-1). Take the comprehensive phosphorus-containing wastewater and pickling and phosphating wastewater from a machinery company in Kunshan 100mL each, add 0.3g and 1.5g of LB-1 dephosphorization agent to each of the phosphorus-containing wastewater, add 1.5g of LB-1 dephosphorization agent to the phosphating wastewater, react for 10min, take out and measure Phosphorus content in the wastewater after the reaction is measured by ammonium molybdate spectrophotometry (GB 11893-89), and the specific results are shown in Table 1 below:

[0023] Table 1 Comparison of phosphorus content before and after treatment of phosphorus-containing wastewater

[0024]

Embodiment 2

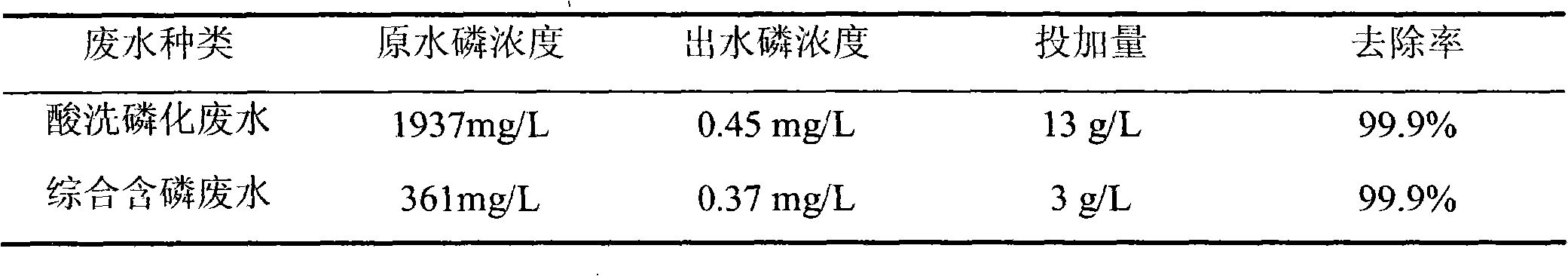

[0025] Embodiment 2: get 60% Ca (NO 3 ) 2 , 15% Al 2 o 3 , 8% FeSO 4 , 17% SiO 2 , through the sol-gel reaction, and then the precipitate after the reaction was dried and sieved to obtain the LB-1 dephosphorization agent. Take 100 mL of comprehensive phosphorus-containing wastewater and pickling and phosphating wastewater from a Shanghai Machinery Co., Ltd., and put Add 0.3g and 1.3g of LB-1 phosphorus removal agent to each of the phosphorus-containing wastewater, react for 20min, take out and measure the phosphorus content in the wastewater after the reaction, and measure it with ammonium molybdate spectrophotometry (GB 11893-89), specifically The results are shown in Table 2 below:

[0026] Table 2 Comparison of phosphorus content before and after treatment of phosphorus-containing wastewater

[0027]

Embodiment 3

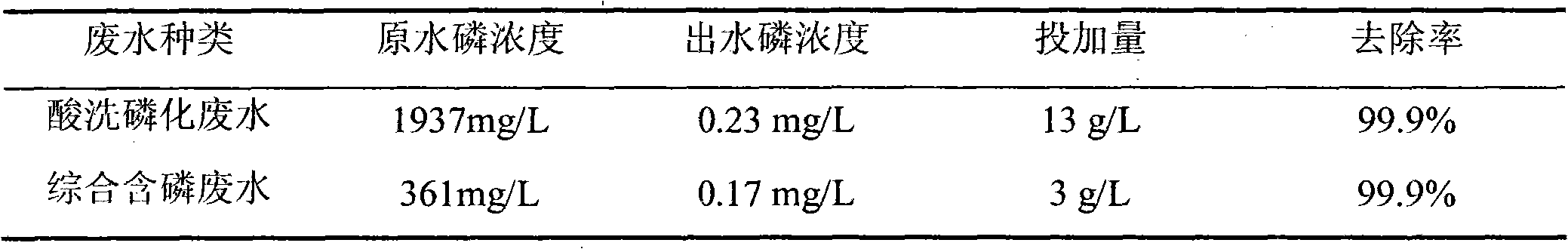

[0028] Embodiment 3: get 80% CaO, 5% AlCl 3 , 5% FeCl 3 , 10% SiO 2 , through the sol-gel reaction, and then the precipitate after the reaction was dried and sieved to obtain the LB-1 dephosphorization agent. Take 100 mL of comprehensive phosphorus-containing wastewater and pickling and phosphating wastewater from a Shanghai Machinery Co., Ltd., and put Add 0.3g and 1.3g of LB-1 phosphorus removal agent to each of the phosphorus-containing wastewater, react for 40min, take out and measure the phosphorus content in the wastewater after the reaction, and measure it with ammonium molybdate spectrophotometry (GB 11893-89), specifically The results are shown in Table 3 below:

[0029] Table 3 Comparison of phosphorus content before and after treatment of phosphorus-containing wastewater

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com