Method for processing burley stems into expanded cut stems

A technology of burley tobacco and shredded stems, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, and can solve the problems that the important role of the Maillard reaction cannot be well played, which is unfavorable for the removal of nicotine nitrogen-containing compounds in Burley tobacco stems, The problems of weak processing resistance of flue-cured tobacco stems have achieved remarkable technical effects, improved smoking quality, and scientific and reasonable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

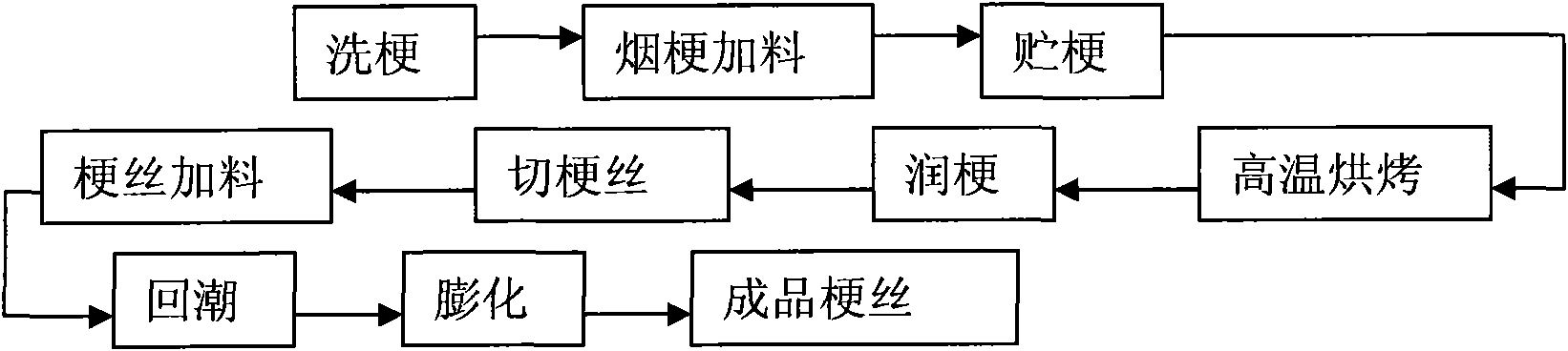

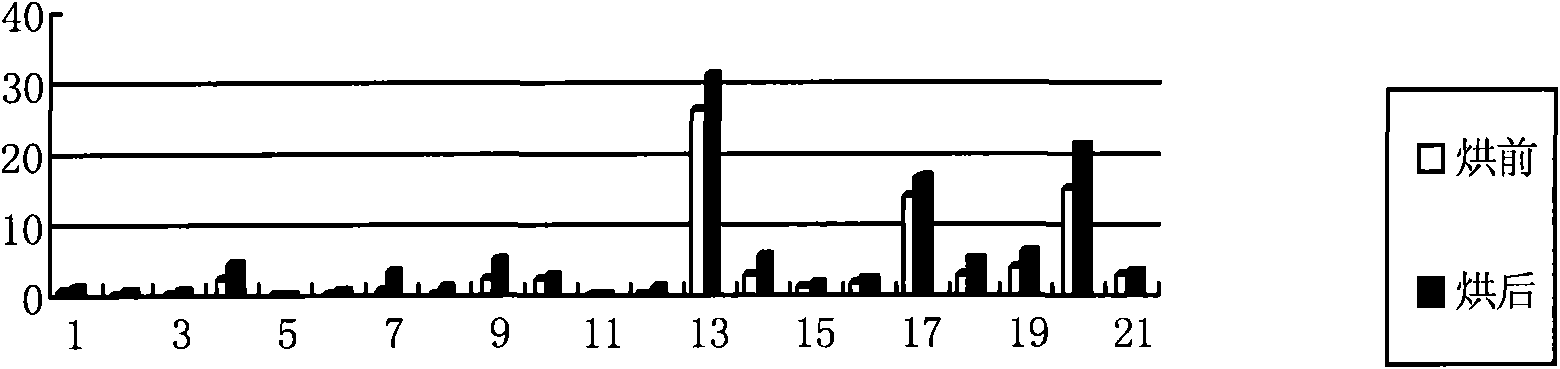

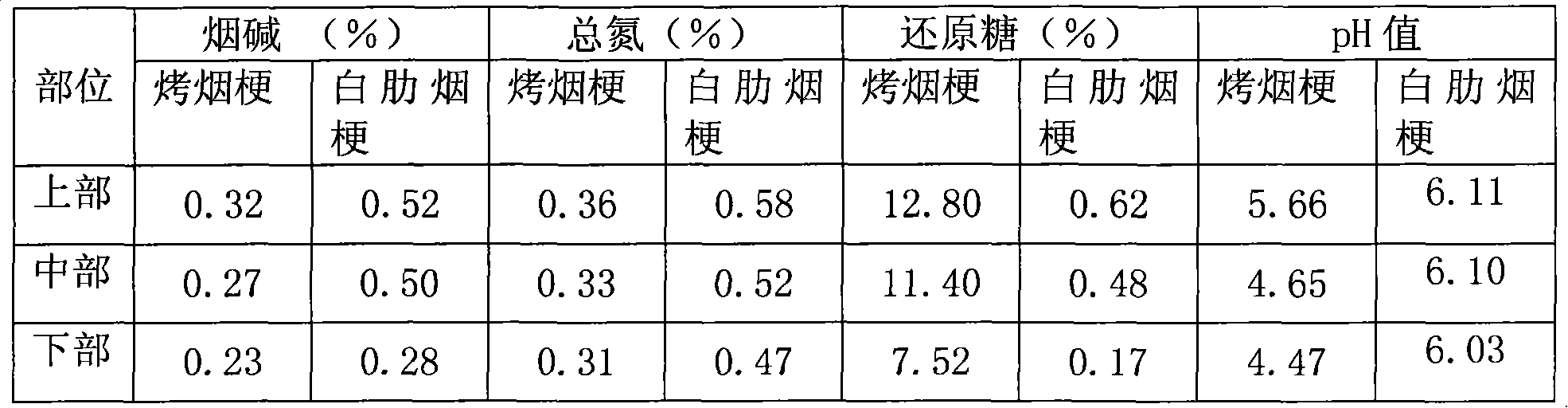

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Maillard reaction mainly refers to a kind of non-enzymatic browning reaction between carbonyl-containing and amino-containing compounds. Many important flavor components can be produced through Maillard reaction, which are widely used in food and tobacco processing. Due to the high content of nicotine and total nitrogen in Burley tobacco stems, Maillard reactants are added by feeding method to make Burley tobacco stems undergo Maillard reaction under high temperature baking conditions, which can make Burley tobacco stems too high The nicotine and nitrogen are converted into many ketones, aldehydes, and pyrazines, which significantly improve the smoking quality of Burley tobacco stems. The method of the present invention is mainly aimed at the special physical and chemical properties of Burley tobacco stems. By adding speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com