Electronic board and cold plate for said board

A technology of electronic circuit board and cooling plate, which is applied in the direction of circuit, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of complex manufacturing and processing of inserts, and achieve the effect of improving cooling efficiency and reducing cooling differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description, features and functions well known to those skilled in the art will not be described in detail.

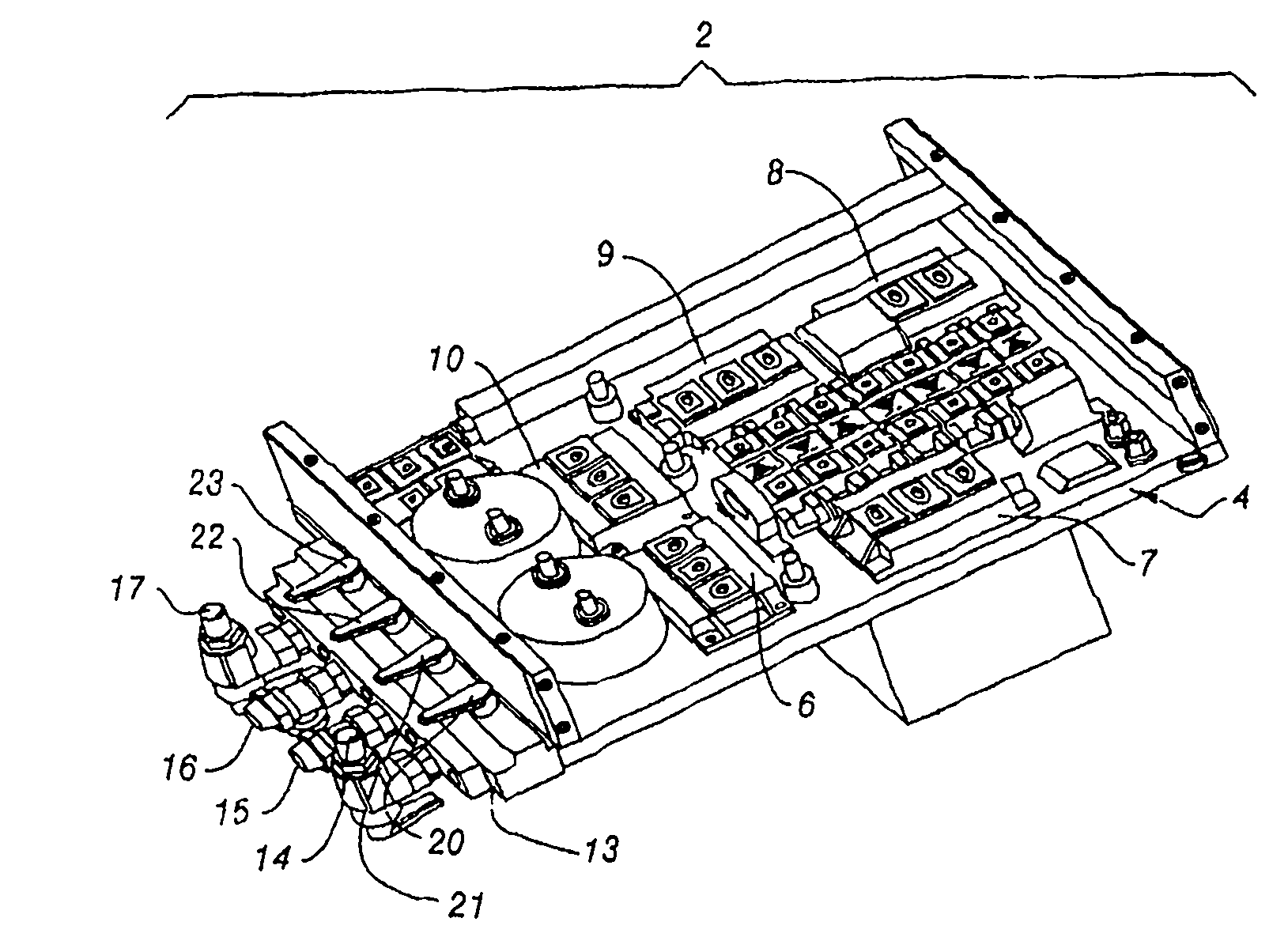

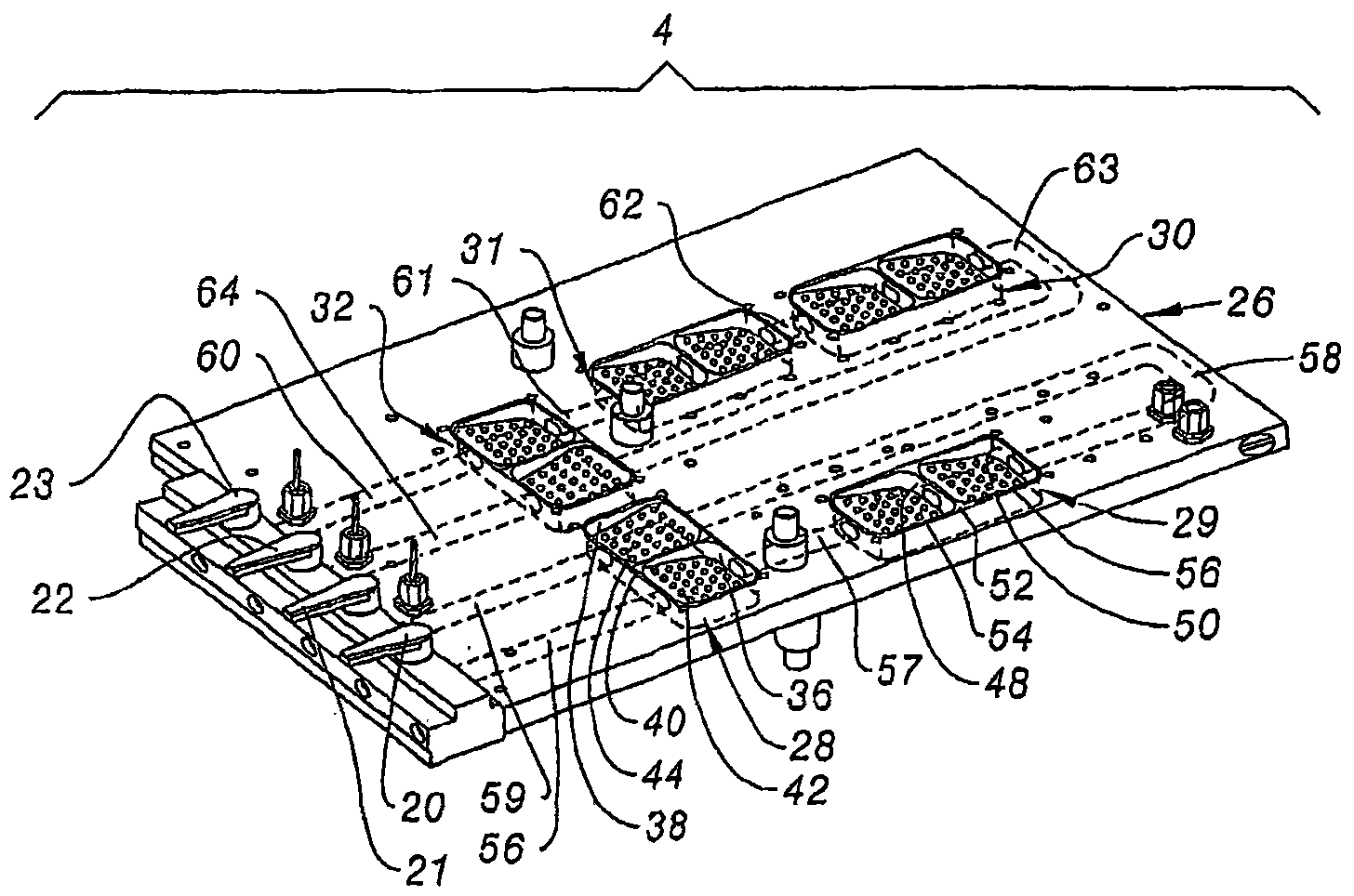

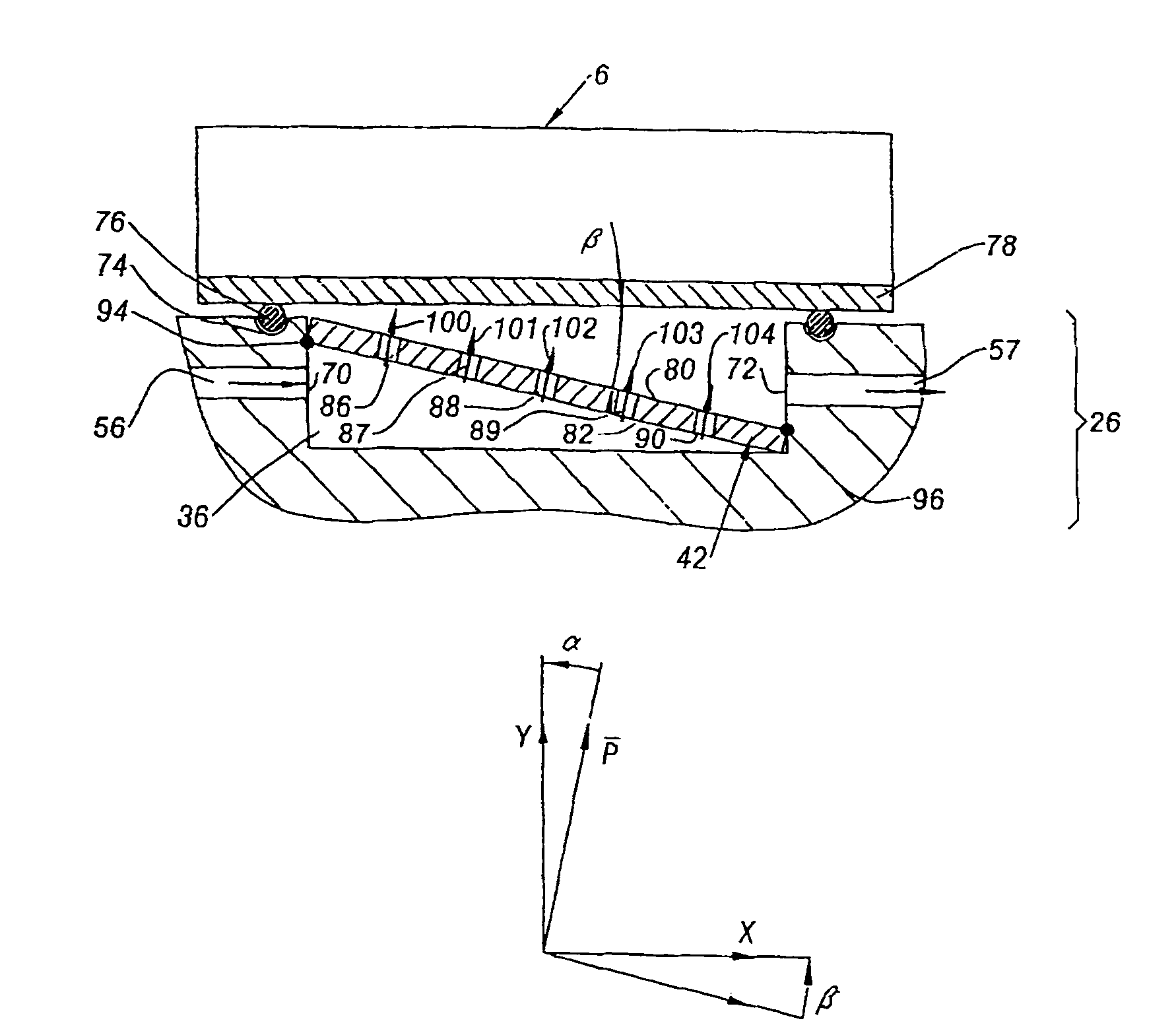

[0039] figure 1 An electronic circuit board 2 is shown with a plurality of electronic power components mounted on a cooling plate 4 .

[0040] Here, the electronic power element refers to an element that can pass an alternating current or direct current of tens of amperes without being damaged. Typically it involves a switch capable of switching this current.

[0041] Here, the circuit board 2 has five power switches 6 to 10 . These power switches are implemented with IGBT transistors (Insulated Gate Bipolar Transistors). figure 1 The other electronic components shown are not necessary to understand the operation of the cold plate and therefore will not be described in detail here.

[0042] One side of the cooling plate 4 has a positioning plane 13 which removably receives four connections 14 to 17 for fluidly connecting the cooling plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com