Buttonhole sewing machine

A sewing machine and buttonhole technology, which is applied to sewing machine components, needle holders for sewing machines, sewing equipment, etc., can solve the problems of many transmission links, large transmission space, and less compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

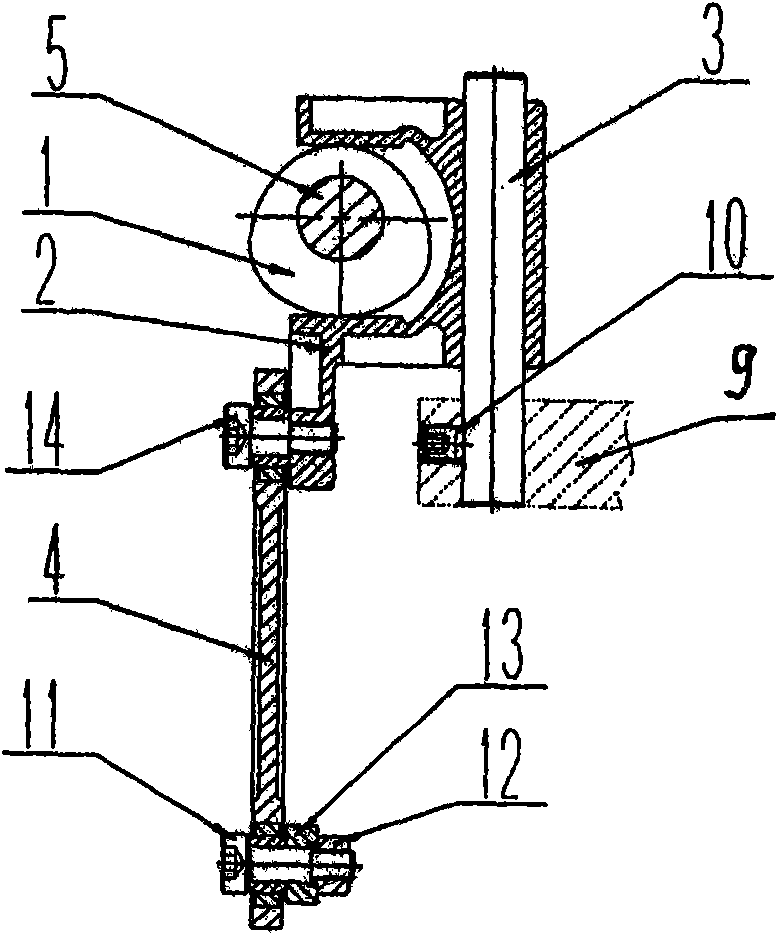

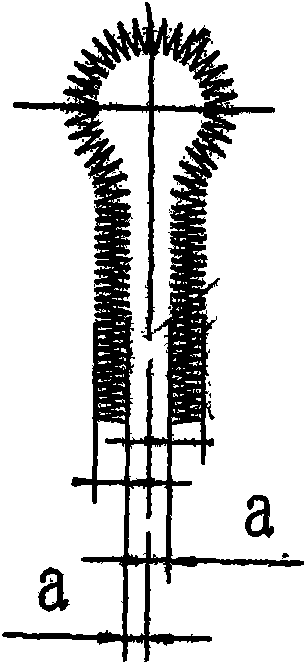

[0013] see figure 1 , figure 2 , Figure 4 and Figure 5 , a buttonhole sewing machine, which includes a casing 8, an upper casing 9, a machine shaft 25, a needle bar 26 for installing an inner needle, a cloth feed table that moves in an x-y horizontal coordinate system and a looper under the cloth feed table, the machine The shaft 25 drives the needle bar 26, and the needle bar 26 moves up and down to pierce the cloth and forms the seam of the buttonhole with the looper. The swing needle cam 1 is arranged at the front end of the machine upper case 9, and the swing needle cam 1 drives a fork-shaped reciprocating rod 2 To move up and down, the fork-shaped reciprocating rod 2 is hinged to a swing rod mechanism 13 through a connecting rod 4, and the rear end of the swing rod mechanism 13 is hinged to a shift lever 16, and the shift fork on the shift ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com