Twisting device of ultra-fine nylon stretch yarn

A technology of twisting device and elastic yarn, applied in textiles, papermaking, yarn and other directions, can solve the problems of reducing the quality of nylon elastic yarn, increasing the number of feeding bobbin doffing, increasing twisting yarn knots, etc., to achieve uniform twist Good quality, low working energy consumption, and the effect of improving twisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

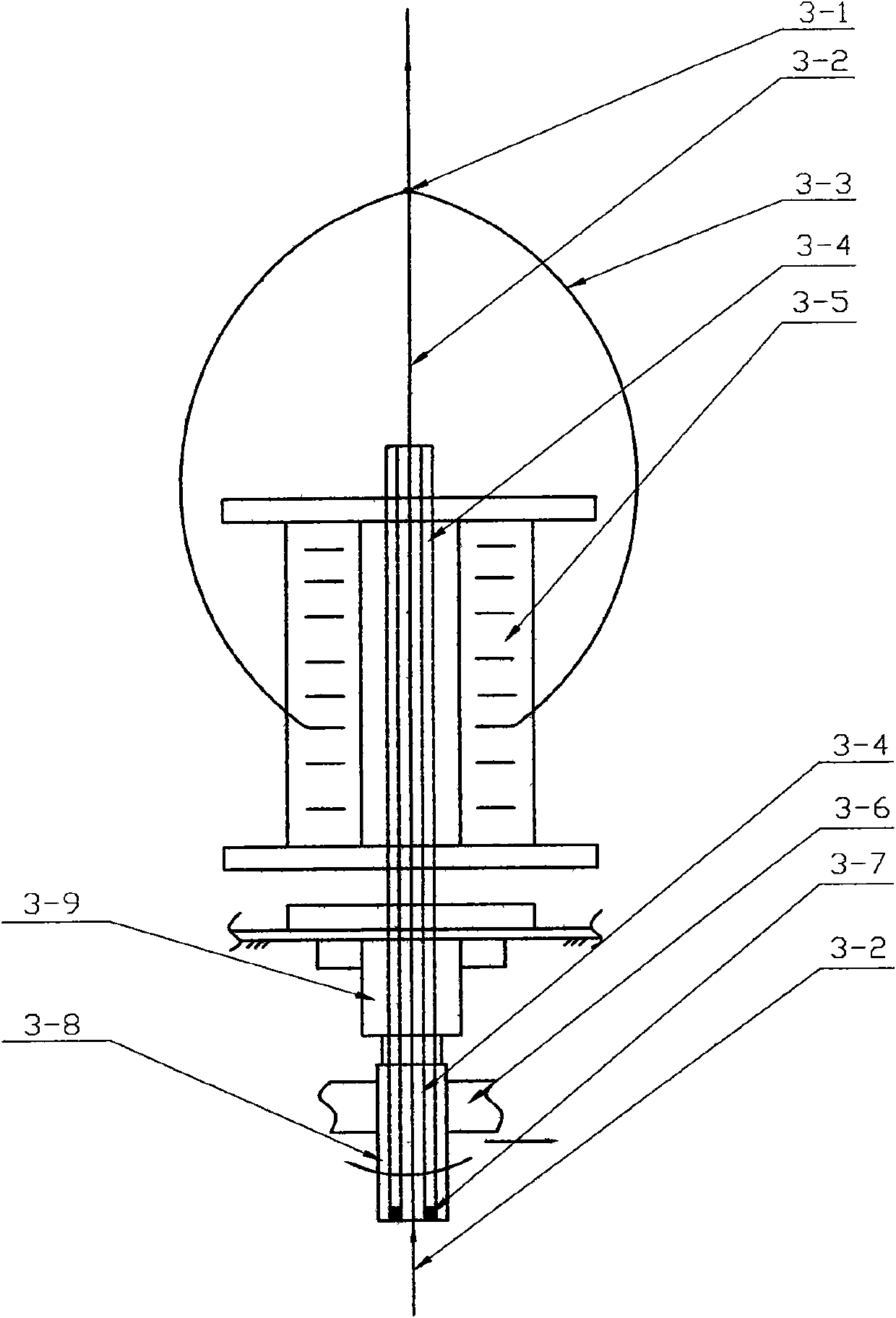

Embodiment 1

[0029] Such as figure 2 As shown, the spindle disk 1-7 is fixed on the fuselage through the spindle base 1-14, the twist disk 1-6 is connected with the spindle disk 1-7, and the yarn pot 1-4 passes through the bearing transition and is installed on the twist disk 1-6. Above, there is no bending porcelain part 1-20 at the middle horizontal hole of the twist disc 1-6, and the outlet of the outer end of the horizontal hole is provided with a wire outlet porcelain part 1-13, and the outer magnet 1-10 is installed in the outer magnetic disk 1-11, The outer magnetic disk 1-11 is fixed on the fuselage; the inner magnet 1-12 is contained in the yarn pot 1-4, and attracts each other with the outer magnet 1-10 to generate a magnetic positioning effect, so that the yarn pot 1-4 is stationary. The feeding bobbin 1-5 is installed in the yarn pot 1-4, the silk thread 1-1 is wound on the feeding bobbin 1-5, the flyer 1-3 is installed on the tension tube 1-9, and on the tension tube 1-9 Amo...

Embodiment 2

[0032] Such as image 3 As shown, the spindle disc 2-7 is fixed on the machine body through the spindle seat 2-14, the rotor cup 2-6 is connected with the spindle disc 2-7, and the stationary cup 2-4 passes through the bearing transition and is installed on the rotor cup 2-6. Inside, the middle horizontal hole of the rotor cup 2-6 is provided with a bending ceramic piece 2-18, and the outlet of the outer end of the horizontal hole is provided with a wire outlet ceramic piece 2-13, and the outer magnet 2-10 is installed in the outer disk 2-11 , the outer magnetic disk 2-11 is fixed on the fuselage; the inner magnet 2-12 is installed in the stationary cup 2-4, and attracts each other with the outer magnet 2-10 to generate a magnetic positioning effect, so that the stationary cup 2-4 is stationary . The feeding bobbin 2-5 is installed in the static cup 2-4, the silk thread 2-1 is wound on the feeding bobbin 2-5, the guide wire cap 2-3 is installed on the tension tube 2-9, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com