Novel conductive roller device

A technology of a conductive roller and a pressing roller device is applied in the surface treatment of metal sheets and strips, and in the field of electroplating tin, which can solve the problems of shortened bearing life, reduced production efficiency, affected lubrication effect, etc., to avoid induced current, improve service life, Avoid the effect of equipment heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

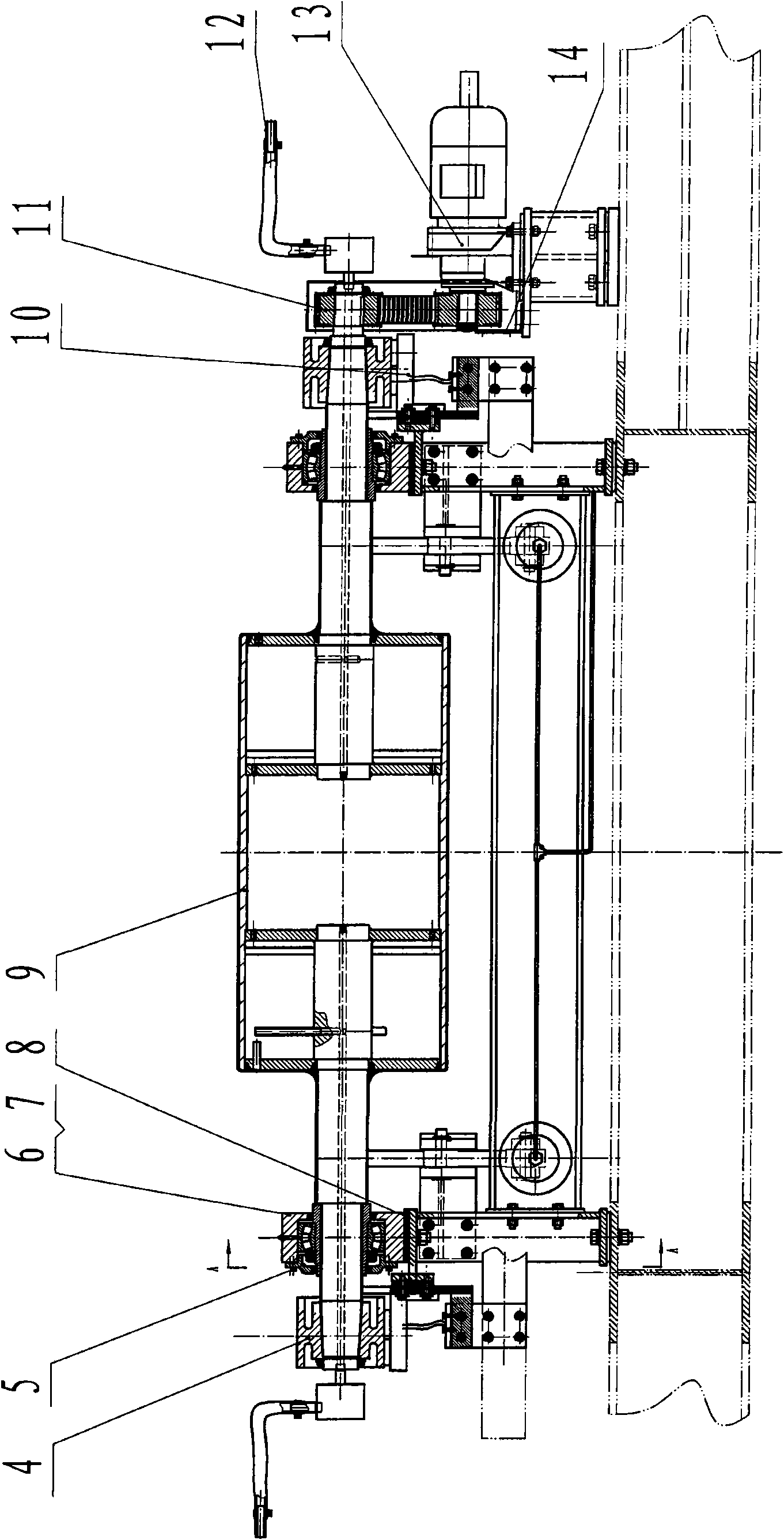

[0012] in the attached Figure 4 In the figure, is the process flow diagram of the reflow section. After cleaning, tinning and hot air blowing, the strip steel passes through the reflow section. The strip steel is used as a resistor between the two conductive rollers 18. After the two conductive rollers are energized, they are heated and grounded. There is a choke coil 17 between the roller 16 and the conductive roller 18. Because the conductive roller 18 has a leakage current, the choke coil is used to generate a reverse induced electromotive force after passing through the alternating current to prevent the current from flowing out and reduce the leakage current through the grounding roller 16. Reduce energy consumption. Heat the tin on the surface of the steel plate to the melting point, and it is in a molten state, and the combination of tin and iron on the surface of the strip steel forms FeSn 2 After the steel strip passes through the water quenching tank 19, it is quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com