Method for preparing dimethyl ether with high purity by syngas one-step method

A dimethyl ether, high-purity technology, applied in the field of producing high-purity dimethyl ether, can solve the problems of energy waste, unseparated and utilized carbon dioxide, large consumption of additional energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

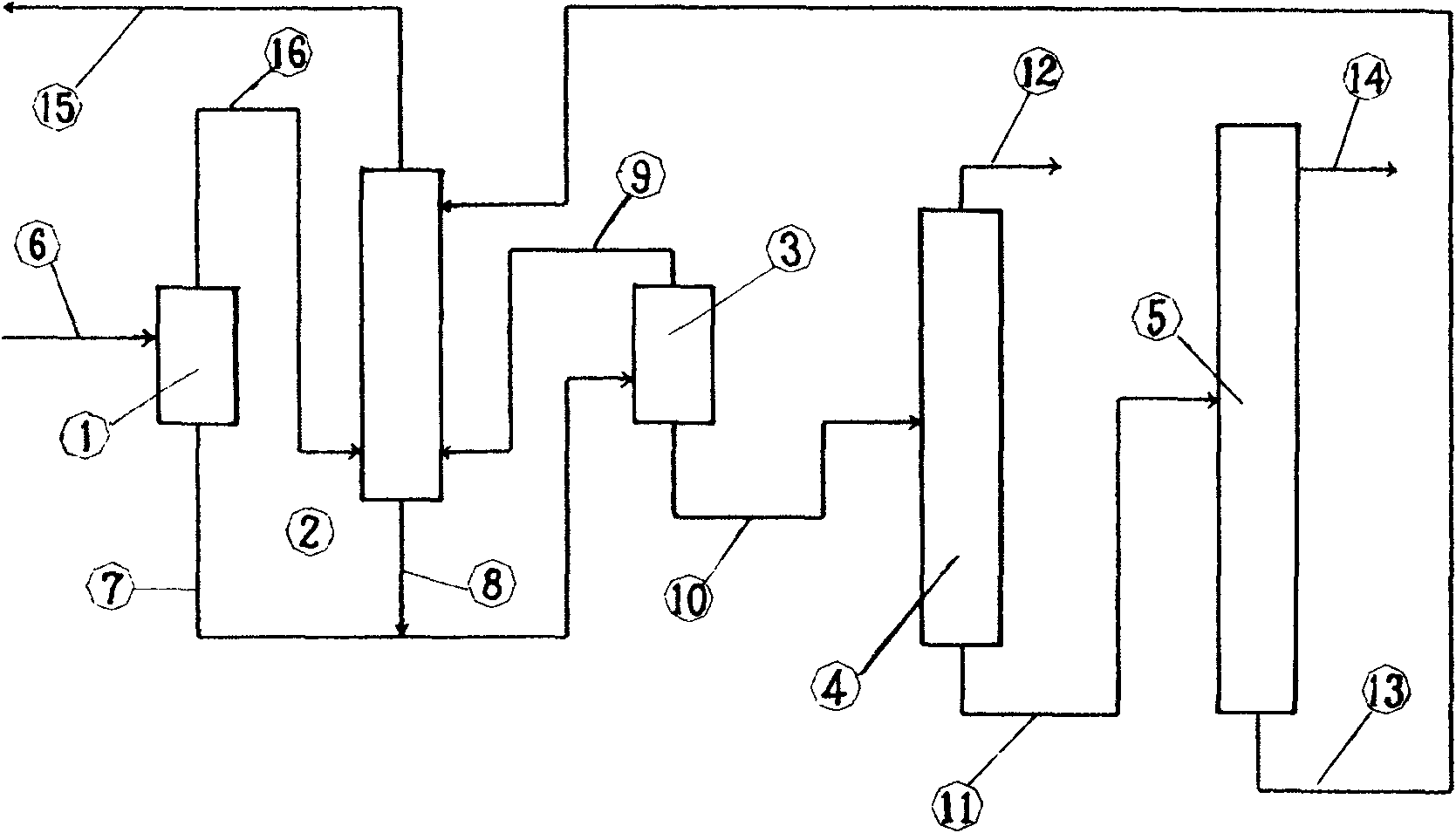

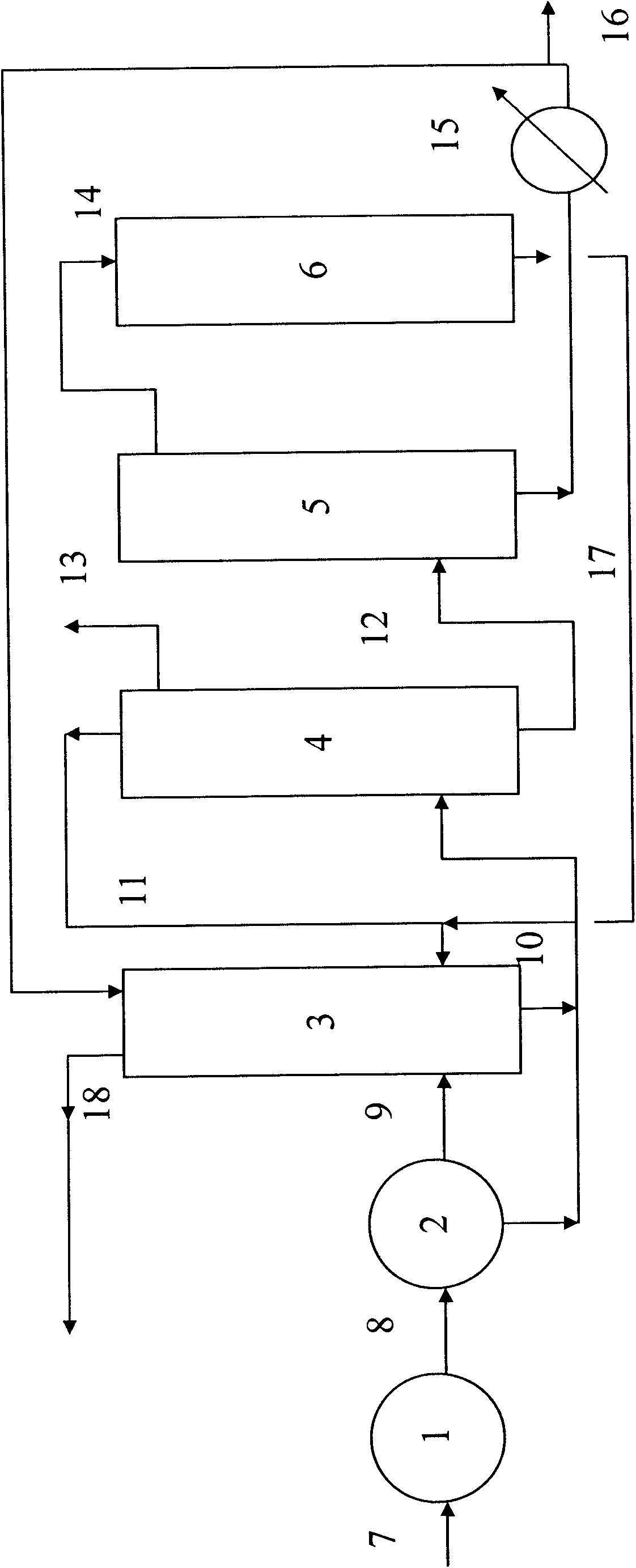

[0043] The method for producing high-purity dimethyl ether by the one-step method of synthesis gas of the present invention is further explained below in conjunction with accompanying drawing.

[0044] A method for preparing high-purity dimethyl ether from synthesis gas in one step. The reaction product (7) enters the gas-gas heat exchanger (1) at a pressure of 3.0-6.0 MPa and a temperature of 230-260° C. After the gas-gas heat exchanger (1) has exchanged heat, the gas phase (8) enters the water cooler (2) at a pressure of 3.0 to 6.0 MPa and a temperature of 80 to 110° C., wherein pure water ( 15) The temperature after cooling is 40-60°C; the gaseous phase (9) after the condensation of methanol-based liquid enters the lower part of the absorption tower (3) at a pressure of 2.5-3.5Mpa and a temperature of 40-60°C, The dimethyl ether and carbon dioxide are absorbed by pure water (15) as an absorbent, and the mixed gas (18) is drawn from the top of the absorption tower (3), and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com