Compound welding method of simultaneously explosive welding of multiple local parts in metal explosive welding

A technology of explosive welding and composite welding, which is applied in the field of metal explosive welding multiple partial simultaneous explosive welding and composite welding, which can solve the problems of low production efficiency, inconvenient construction on site, waste of raw materials, etc., and improve welding quality, improve construction efficiency, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

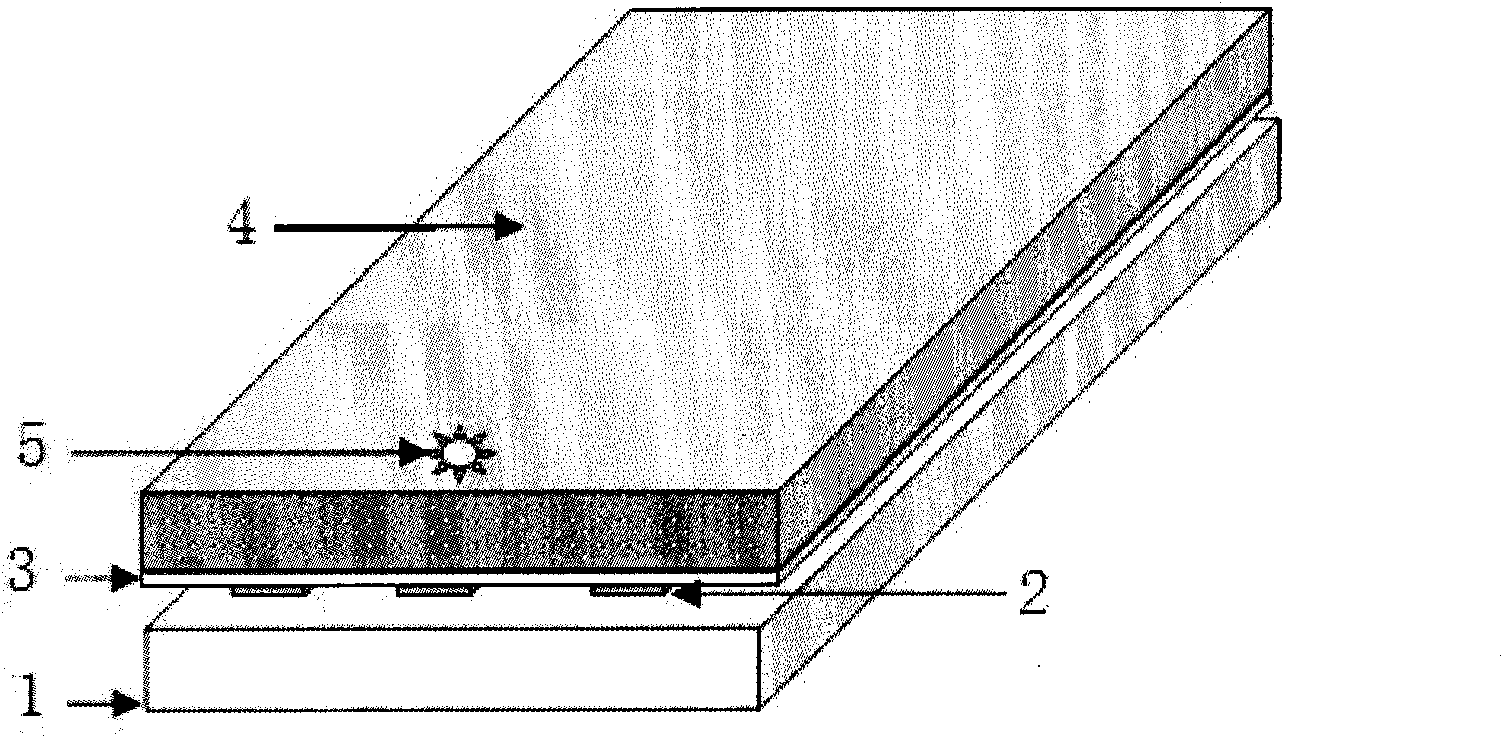

[0059] see figure 1 , a metal explosive welding multiple local simultaneous explosive welding composite welding method, the welding device comprises a base copper metal plate 1, the base copper metal plate 1 is placed with a clad silver metal plate 2, and the shape of the clad silver metal plate 2 is The shape can be strip, block, plate, ring, circle or rectangle. A medicine frame is arranged on the lining plate, and the medicine frame is evenly covered with explosives 4 and detonators 5 .

[0060] The whole welding device is placed on the sand foundation, and the detonator is detonated for explosive welding construction; then the residues on site are removed, and the surface quality of the welded clad metal plate is inspected; ultrasonic nondestructive testing and mechanical properties of the clad metal plate are carried out. It can detect and level the clad metal plate; heat treatment, cut and stamp the leveled clad metal plate.

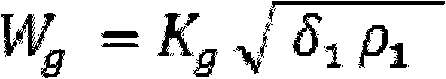

[0061] The process parameters of metal exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com