Etching method and recording medium

一种蚀刻、硬质的技术,应用在放电管、电气元件、电固体器件等方向,能够解决蚀刻选择比低、加工形状不够充分等问题,达到表面形状良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

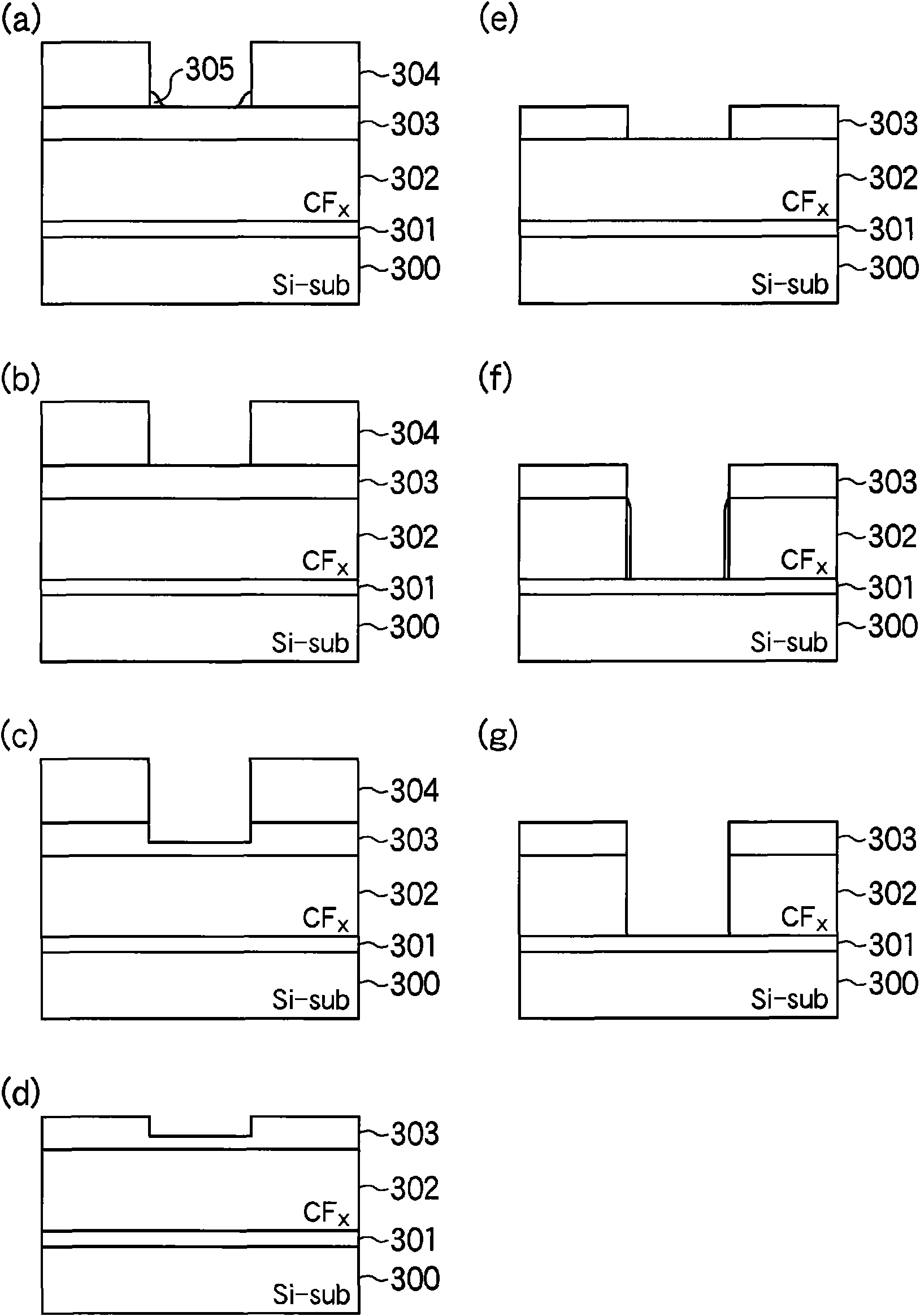

[0052] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0053] figure 1 It is a sectional view showing an example of a plasma processing apparatus capable of carrying out the etching method of the present invention. This plasma processing apparatus is of a type that forms a capacitively coupled plasma using a pair of parallel plate electrodes disposed facing up and down.

[0054] Such as figure 1 As shown in the schematic configuration shown in , the plasma processing apparatus 10 includes a processing chamber 11 formed in a substantially cylindrical shape, a susceptor support table 14 is disposed at the bottom of the chamber with an insulating plate 13 interposed therebetween, and a susceptor 15 is disposed thereon. . The susceptor 15 also serves as a lower electrode, and a wafer W is placed on the susceptor 15 via an electrostatic chuck 20 . Symbol 16 is a high pass filter (HPF).

[0055] Inside the susceptor supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com