Method and device for wrapping reinforcement yarn around long optical fiber cable

A technology of large length and yarn, applied in the field of fiber optic outer wrapping reinforcing yarn, can solve the problems of low efficiency and large wrapping equipment, and achieve the effect of improving speed and production efficiency, simplifying wrapping equipment and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

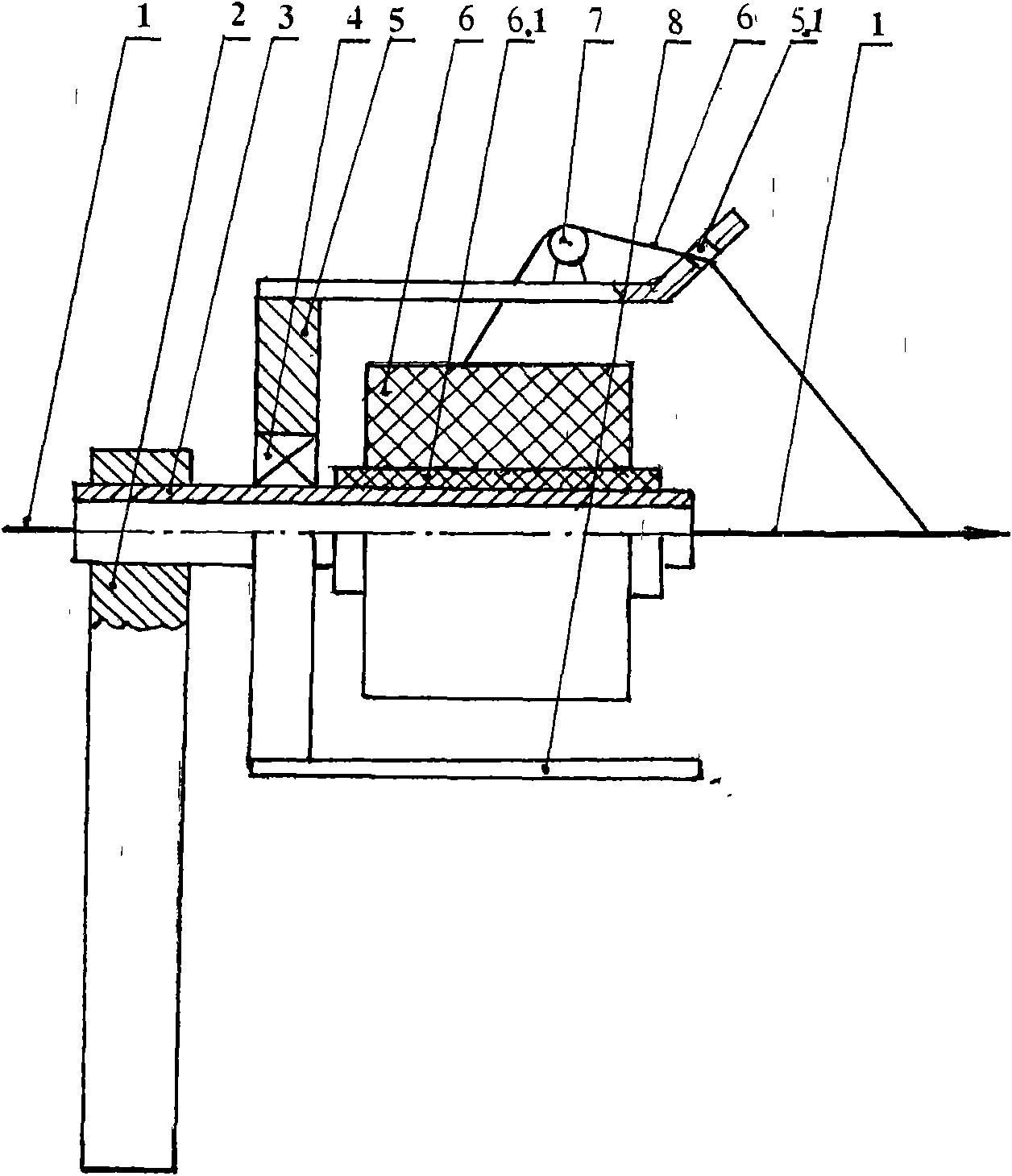

[0010] exist figure 1 Among them, a method for wrapping reinforced yarns of large-length optical cables, which is characterized in that the optical fiber (1) passes through the hollow axis of the hollow fixed shaft (3), and the untwisted yarn (6) passes through the side of the bobbin (6.1) Lead out, through the yarn guide wheel (7) and yarn guide hole (5.1) on the rotary pay-off frame (5), under the continuous rotation of the rotary pay-off frame (5), the untwisted yarn (6) is continuously wound to On the outer side of the advancing optical fiber (1), the yarn bobbin (6.1) and the yarn (6) wound around its outer circumference are rotated 180° left and right to realize the left-handed or right-handed wrapping of the yarn (6) on the optical cable. conversion;

[0011] A wrapping device for reinforcing yarn of a large-length optical cable is composed of a fixed part and a rotating part. The fixed part consists of a fixed frame (2), a hollow fixed shaft (3), a yarn (6) and a bobb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com