Electric resistance heat element for a heating device for heating a flowing gaseous medium

A resistance heating element, heating gas technology, applied in the direction of ohmic resistance heating, heating element material, heating element shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

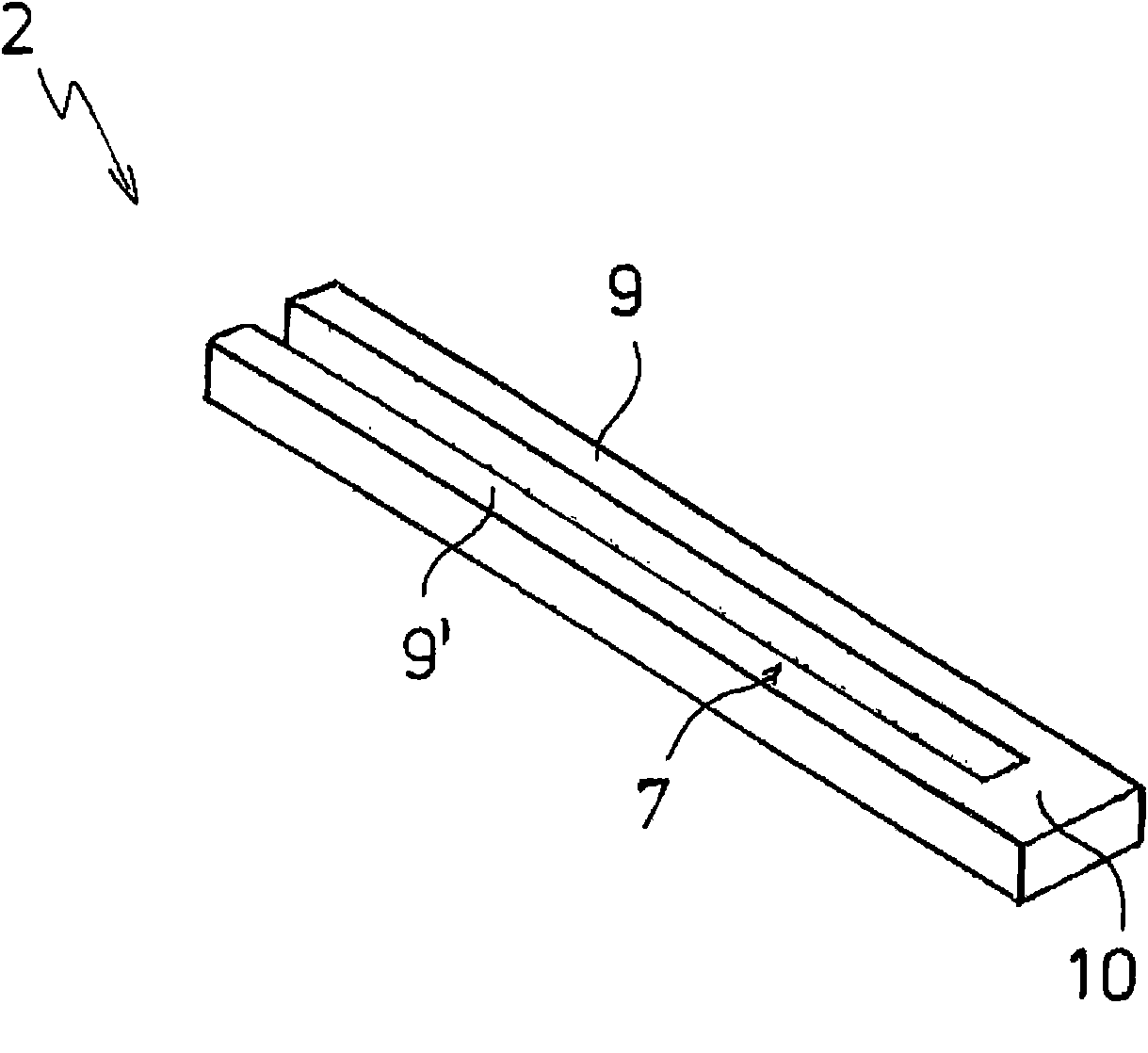

[0036] figure 1 An embodiment of a resistive heating element 1 according to the invention is shown having four heating resistors 2 in axial section, only two of which are visible in the drawing. The heating resistor 2 is substantially rod-shaped and has front and rear end portions 3 , 4 . The rear end part 4 is associated with the air inlet side 5 and the front end part is associated with the air outlet side 6 of the resistance heating element 1 . The heating resistor 2 is U-shaped and has a flat surface 7, ends 8, 8', limbs 9, 9' and a base 10 connecting the limbs 9, 9'. The ends 8' of the heating resistor 2 are connected in an electrically conductive manner by means of a bridge 11. The power supply line 12 leads to the end 8 of the heating resistor 8 .

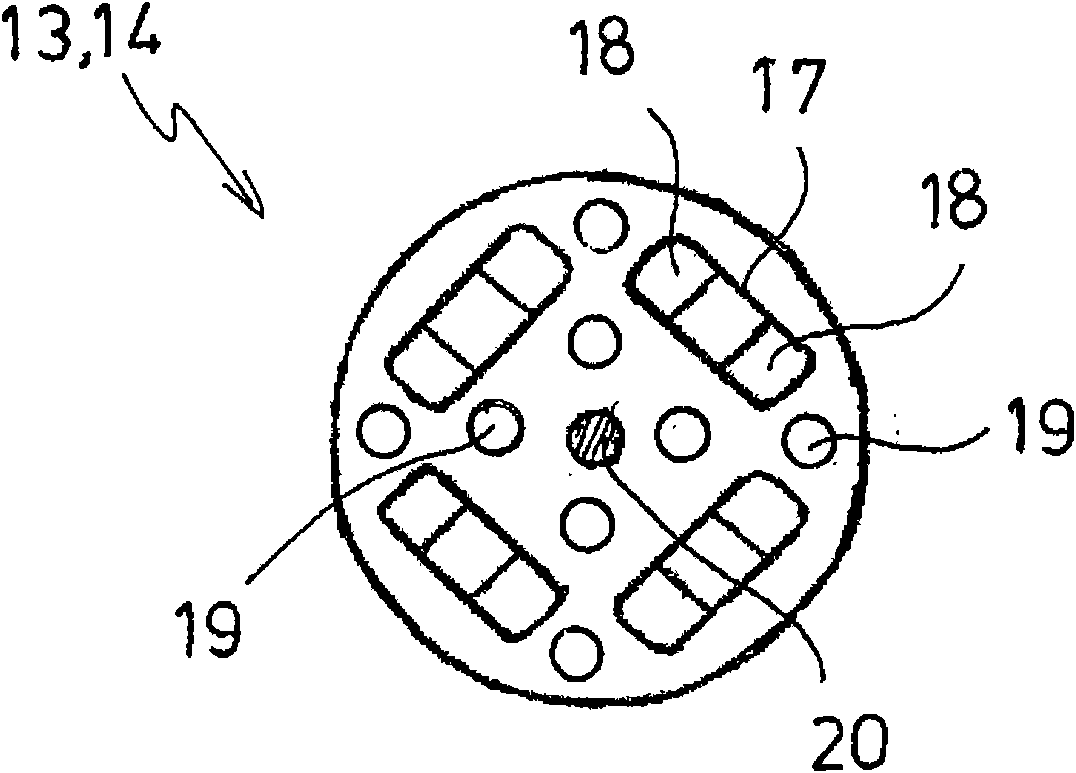

[0037] The heating resistor 2 is held by front and rear carrier plates 13 , 14 . The base 10 actively engages the front carrier plate 13 on the air outlet side and the two facing ends 8, 8' actively engage the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com