Method and device for telemetering torque moment of drill stem

A drill pipe and kelly technology, applied in drill pipe, drill pipe, measurement and other directions, can solve the problems of poor anti-scour ability, inconvenient installation, low accuracy, etc., and achieve the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

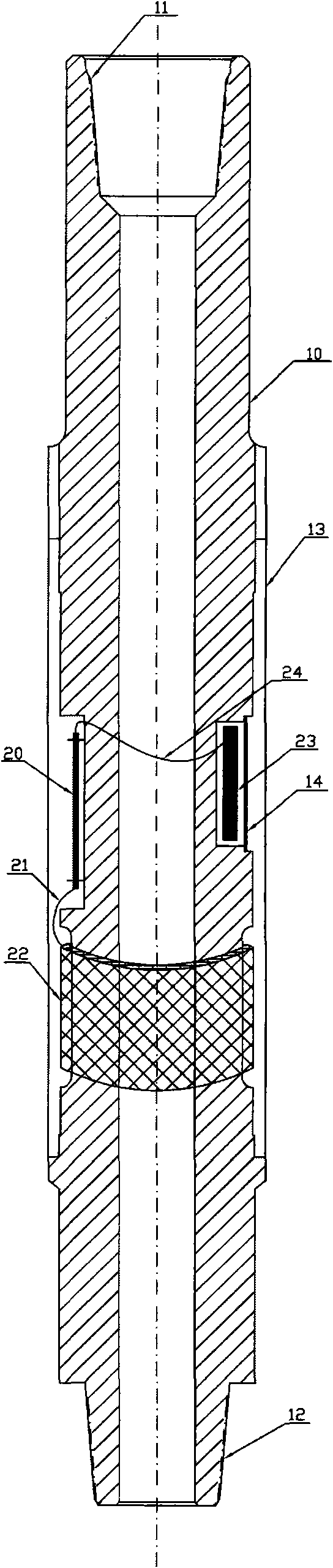

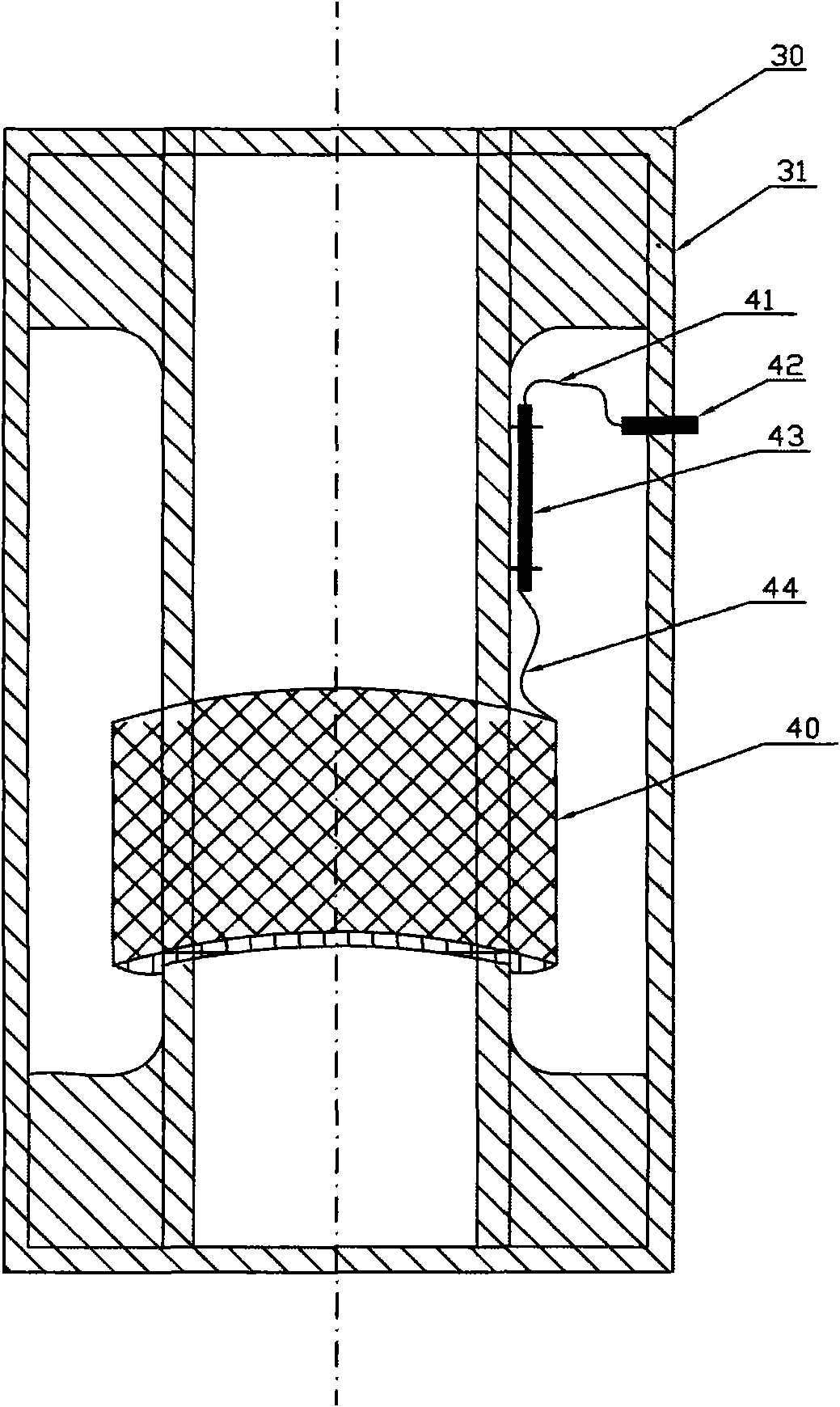

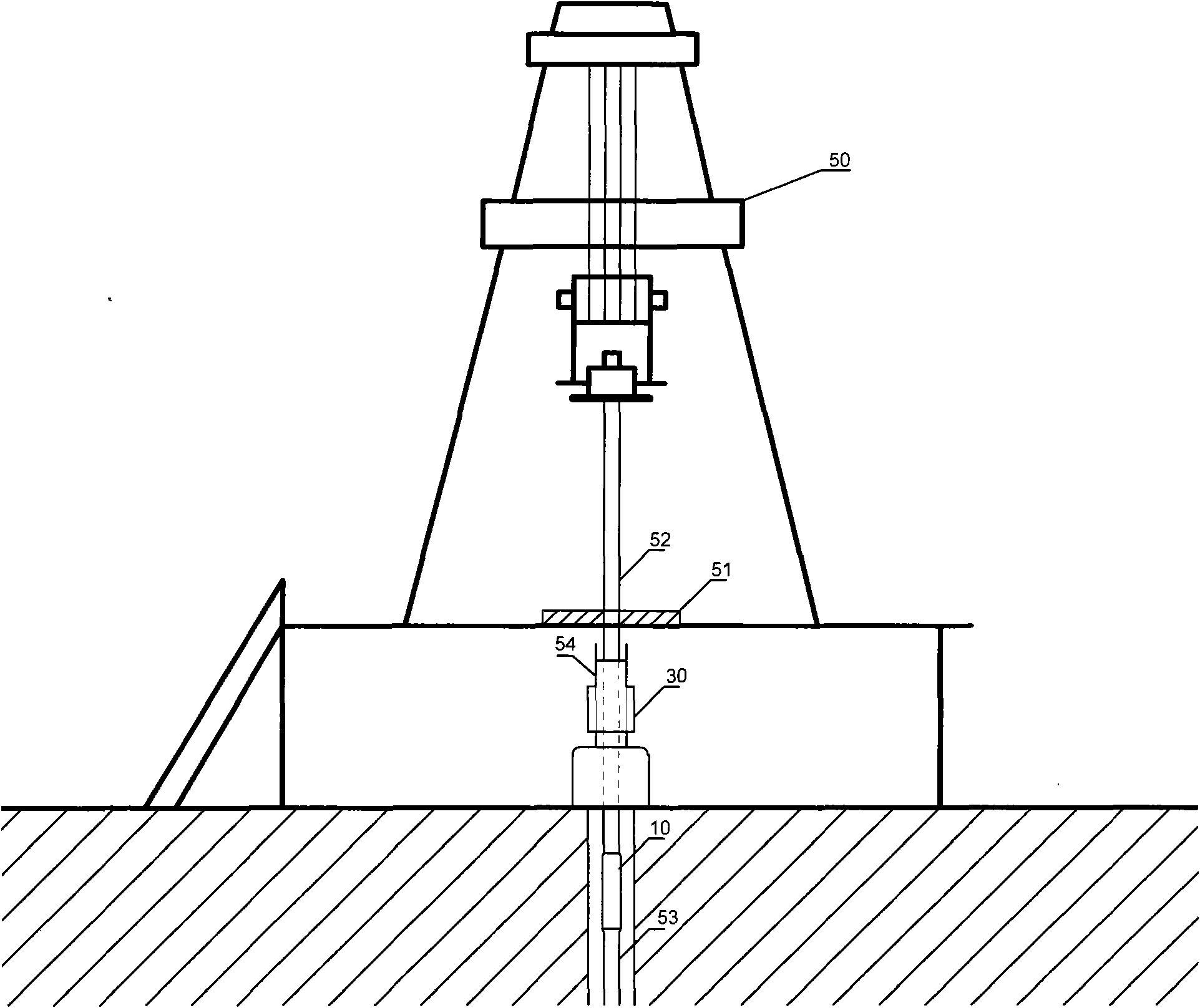

[0012] The implementation method of applying the method and device to the diesel engine power drilling rig 50 is as follows: before running in the drill, the lower short connector 10 is connected with the lower end of the kelly 52 through the female thread 11, connected with the drill rod 53 through the male thread 12, and the upper short Connector 30 is installed at the position of bell mouth 54. Connect connector 42 to the control room through an external cable. The external cable is a four-core shielded cable, two of which are for power supply, and the other two are for communication. The shielding layer is grounded, and the short circuit is completed at this time. Install. When drilling starts, the turntable 51 drives the kelly to rotate, and the parameter collection board 20 collects the torque parameter through the sensor, packs, modulates, and amplifies the power, and then transmits the parameter to the sending coil 22 through the communication cable 21, and the sending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com