Method for reinforcing integral replacement concrete for high-rise building steeel bar concrete column

A technology for high-rise buildings and steel bars, applied in construction, building maintenance, building construction, etc., can solve problems such as inability to effectively deal with unqualified reinforced concrete frame columns, and achieve the effect of small economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Taking square columns, four steel pipe supports, and four section steel supports as examples below, the present invention will be described in detail.

[0042] (1) Design of support unloading system

[0043] Due to the huge axial pressure on the lower floors of high-rise buildings, which are generally in the state of axial compression or small eccentric compression, only the vertical pressure can be considered in the calculation of support unloading.

[0044] 1. Beam end unloading support

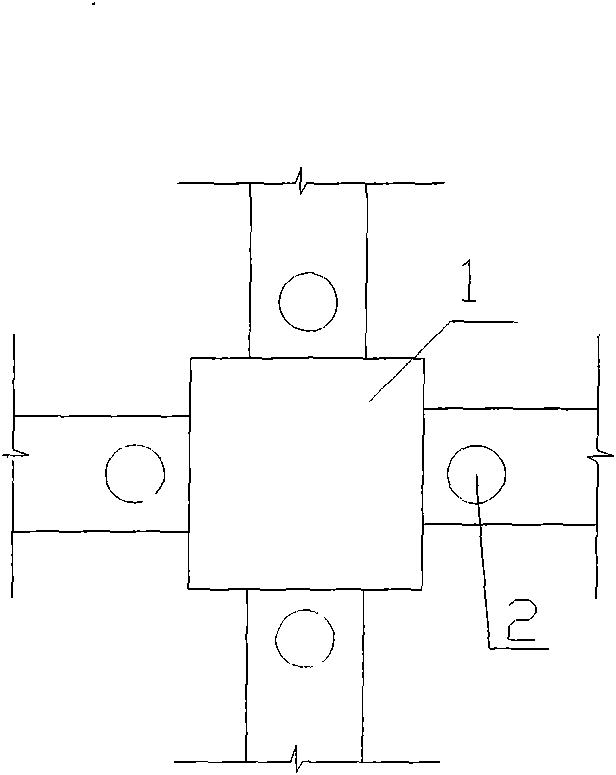

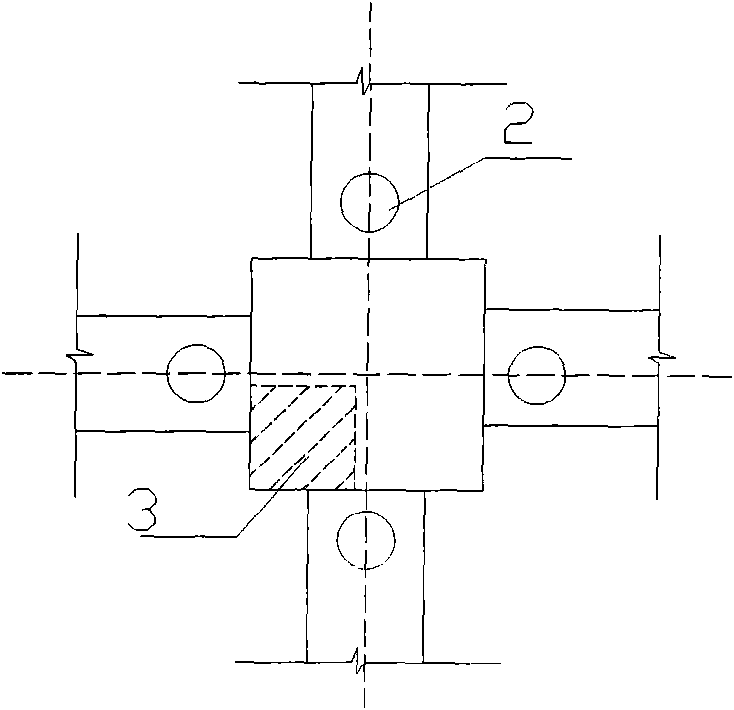

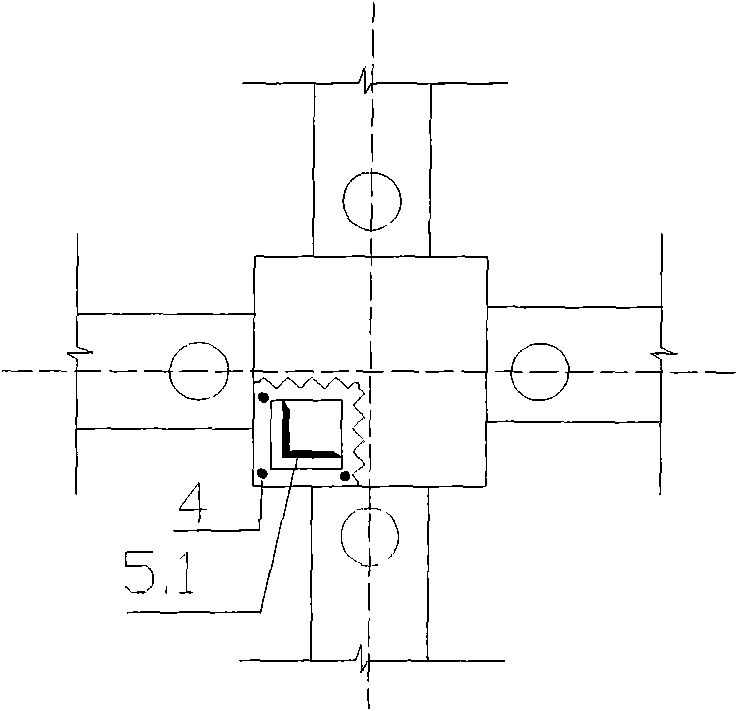

[0045] Such as figure 1 As shown, first set up two (corner columns), or three (side columns), or four (middle column) steel pipe supports at the beam ends around the frame columns to be replaced, and install screw jacks on the supports, and the jacks will tighten the upper and lower beams end, and use this steel pipe to support part of the load of the detachable column.

[0046] The load that can be unloaded by the steel pipe support is determined according to the following calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com