Precast concrete short-pier shear wall with infilling wall panel and connecting method thereof

A prefabricated concrete and filling technology, which is applied to walls, building components, buildings, etc., can solve the problems that the quality of structural construction is not easy to be guaranteed, the construction method is unfavorable to the environment and energy saving, and the on-site construction procedures and management are complicated, so as to achieve easy construction quality Guarantee, improvement of construction environment and conditions, and reduction of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

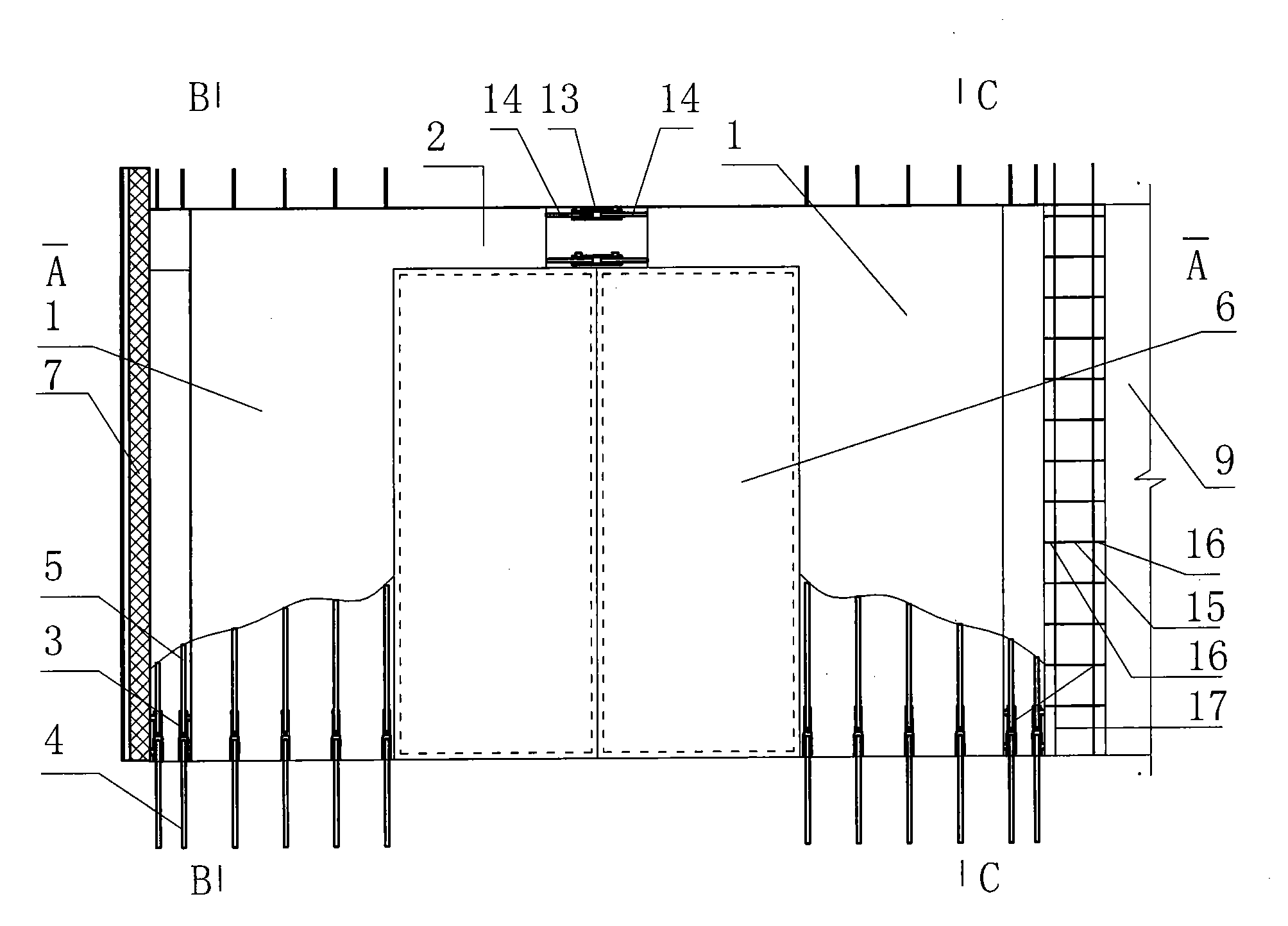

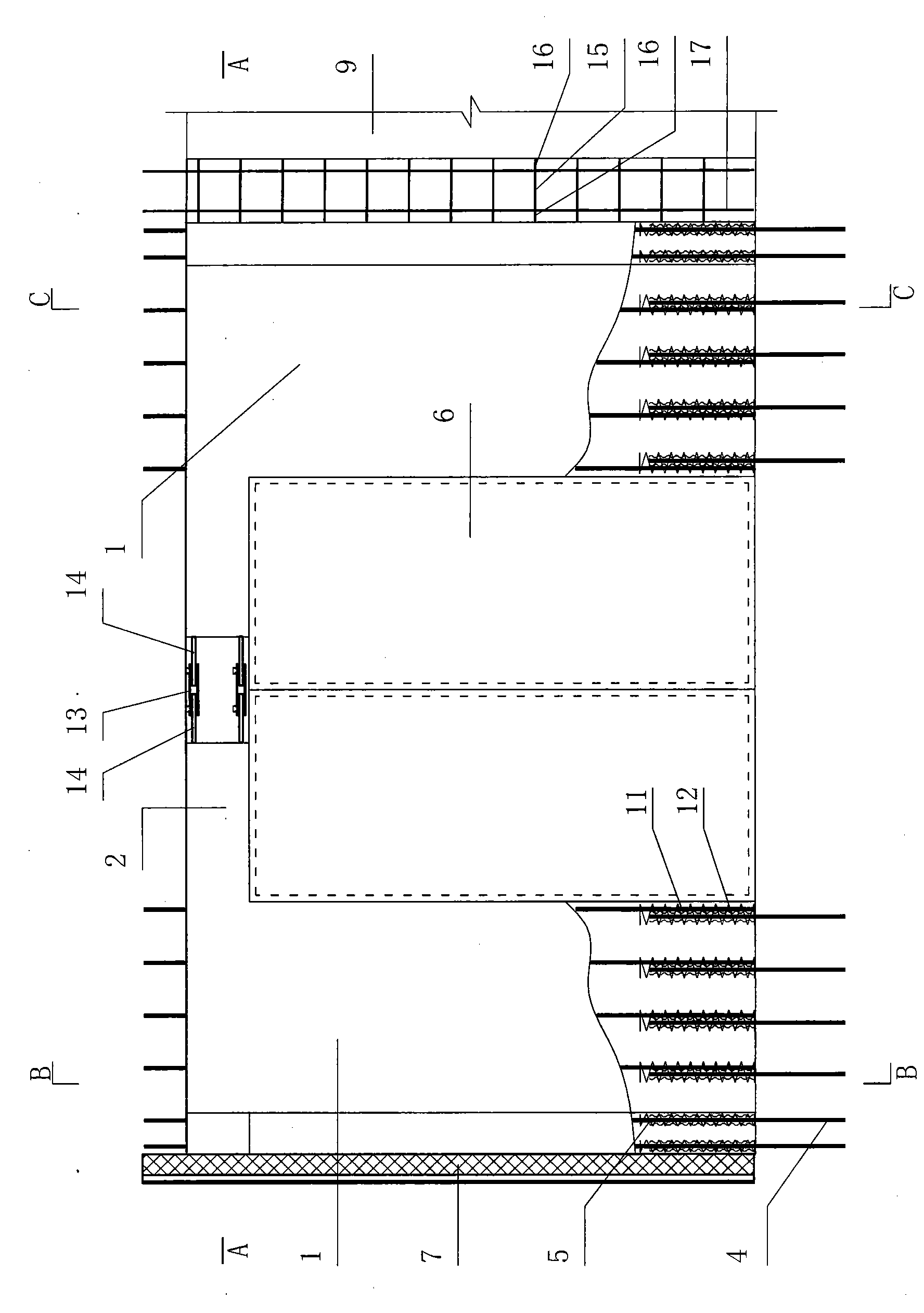

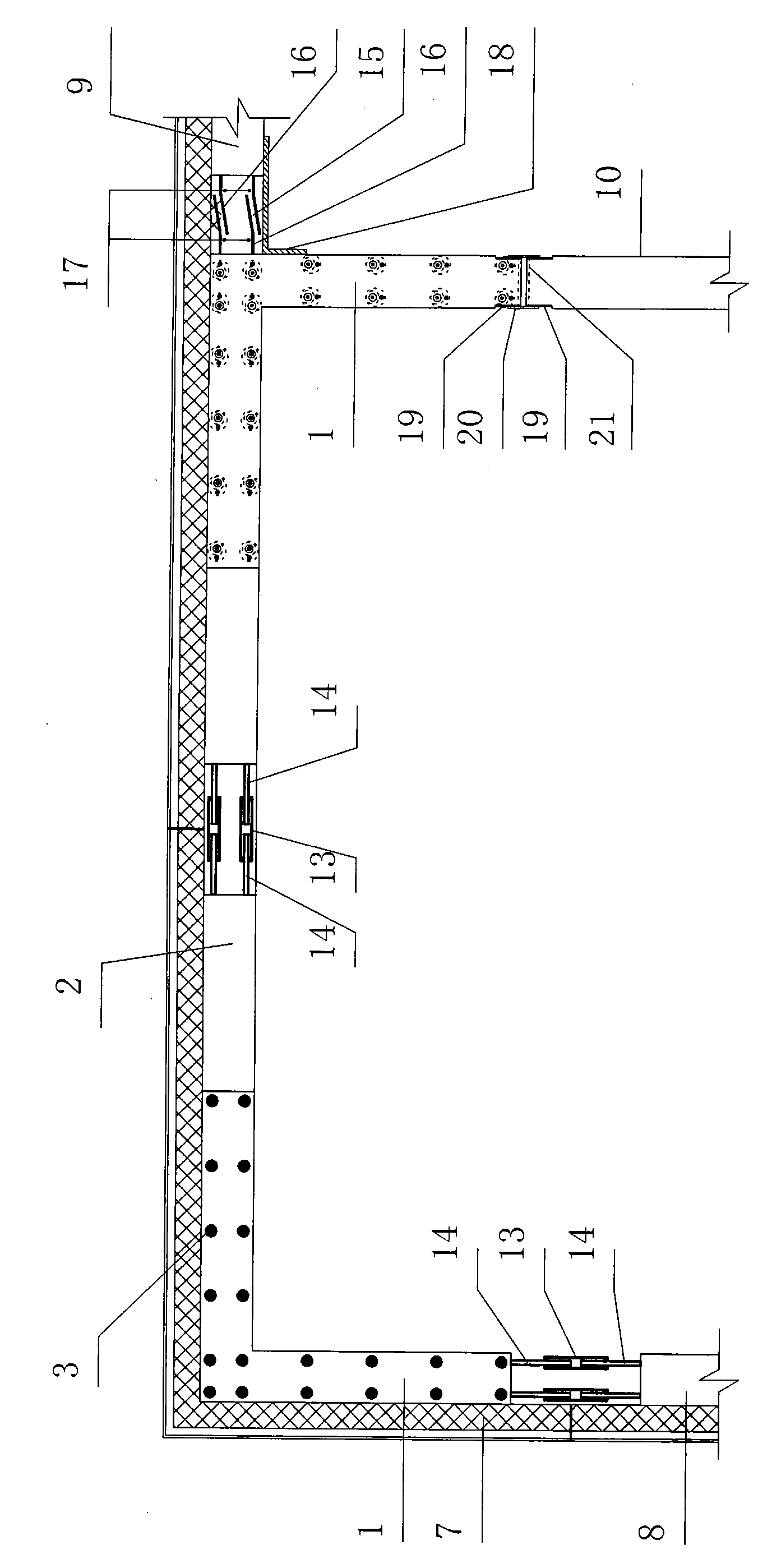

[0023] Prefabricated concrete short-leg shear wall, the parts are composed of wall body 1 and connecting beam 2, the opening formed by the wall body and connecting beam is filled with filling wall panels 6, and when the structural part is an external wall, it is equipped with thermal insulation layer and decoration Topping7. The ratio of the section height to thickness of the wall pier is 5 to 8, and the section shape of the wall pier is "one" or "T" or "L" or "ten".

[0024] First, connect the longitudinal steel bar 5 of the prefabricated short-leg shear wall with the reserved steel bar 4 of the lower layer, that is, the structural parts are hoisted so that the reserved steel bar 4 of the lower layer is inserted into the longitudinal steel bar embedded in the lower end of the longitudinal steel bar 5 of the wall body. In the sleeve 3, and the support adjustment is reliable, the cement-based grouting material is poured through the grouting hole of the longitudinal steel bar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com