Rotary dynamic closed filtering process and device

A rotary dynamic filter device technology, applied in the direction of mobile filter element filter, filter separation, separation method, etc., can solve the problems of turbidity of filtrate, reduction of filtration efficiency, high cost of valve and control circuit, etc., and achieve the stability of internal sweeping flow field , Filtration process is continuous, and the service life is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

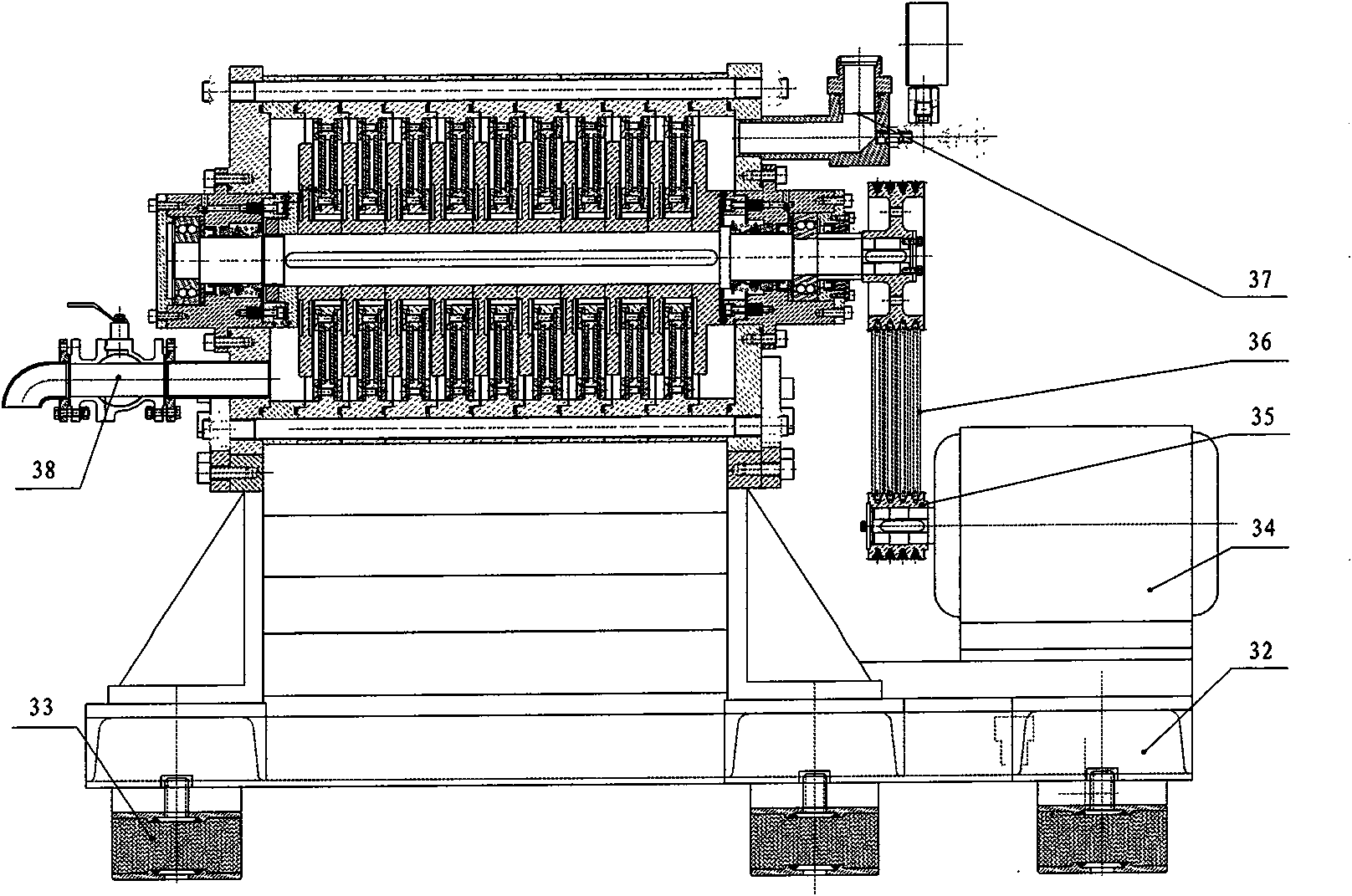

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

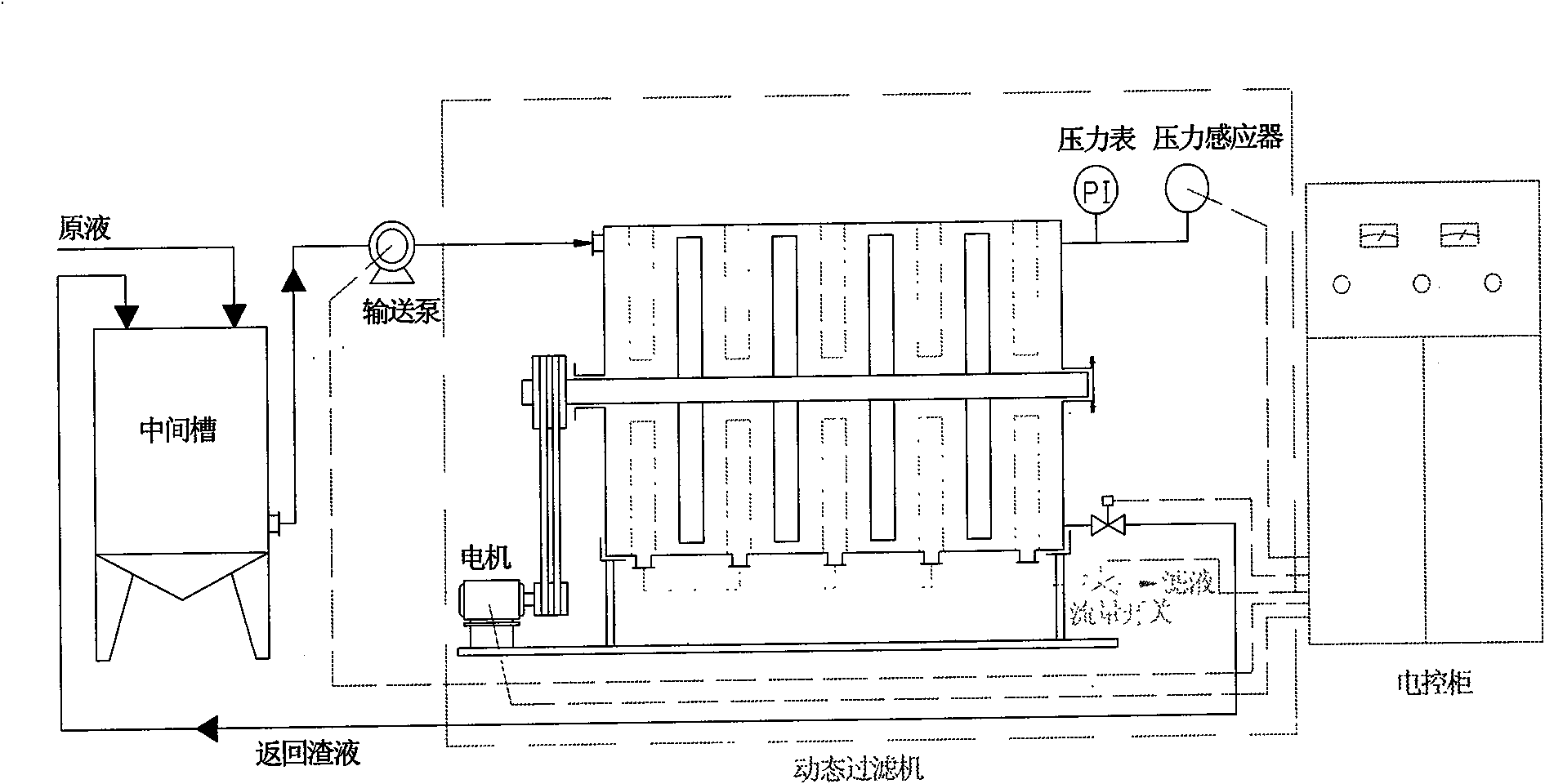

[0034] see figure 1, the filtration process of the present invention changes the valve of the slag liquid discharge port of the original filter from normally closed to normally open, and communicates with the middle tank, the filtrate discharge port is provided with a flow switch, and is connected with the electric control cabinet, and the delivery pump and the driving rotary impeller The running motor is also connected with the electric control cabinet. Firstly, the raw liquid, that is, the suspension to be filtered, or the mother liquid, is sent into the middle tank, that is, the liquid collection tank by self-flow or by pump; then the mother liquid in the middle tank is pressed into the filter chamber of the dynamic filter from the feed port through the delivery pump. , the filtrate is reused or discharged, and the slag is returned to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com