Power assembly for electric automobile

A powertrain and electric vehicle technology, applied in the direction of electric vehicles, electric power units, power units, etc., can solve the problems of large position changes, increased design costs and manufacturing costs, and insufficient cabin space to achieve compact structure and cost savings , the effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

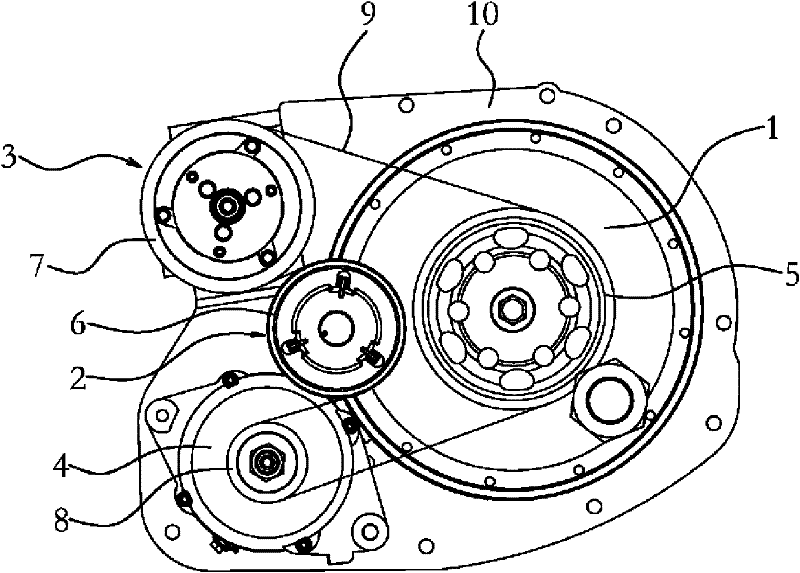

[0016] Such as figure 1 As shown, the power assembly of the electric vehicle includes a driving motor 1, a water pump 2, an air-conditioning compressor 3 and a generator 4, and their drive shafts are parallel to each other, and the water pump 2, the air-conditioning compressor 3 and the generator 4 are all located at the drive On the same side of the motor 1, the output shaft end of the drive motor 1 is fixed with a driving pulley 5, and the shafts of the water pump 2, the air conditioner compressor 3 and the generator 4 are respectively fixed with a driven pulley 6, 7, 8. The driving pulley 5 is connected to each driven pulley 6, 7, 8 through the transmission belt 9, and the drive motor 1 is powered by a power battery, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com