Lacquer painting processing composition, lacquer painting processing method and lacquer painting mending method

A technology for treating compositions and paint surfaces, applied in the fields of low-gloss paint surface treatment compositions and low-gloss paint surface abrasive pastes, and can solve problems such as storage time and storage condition limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

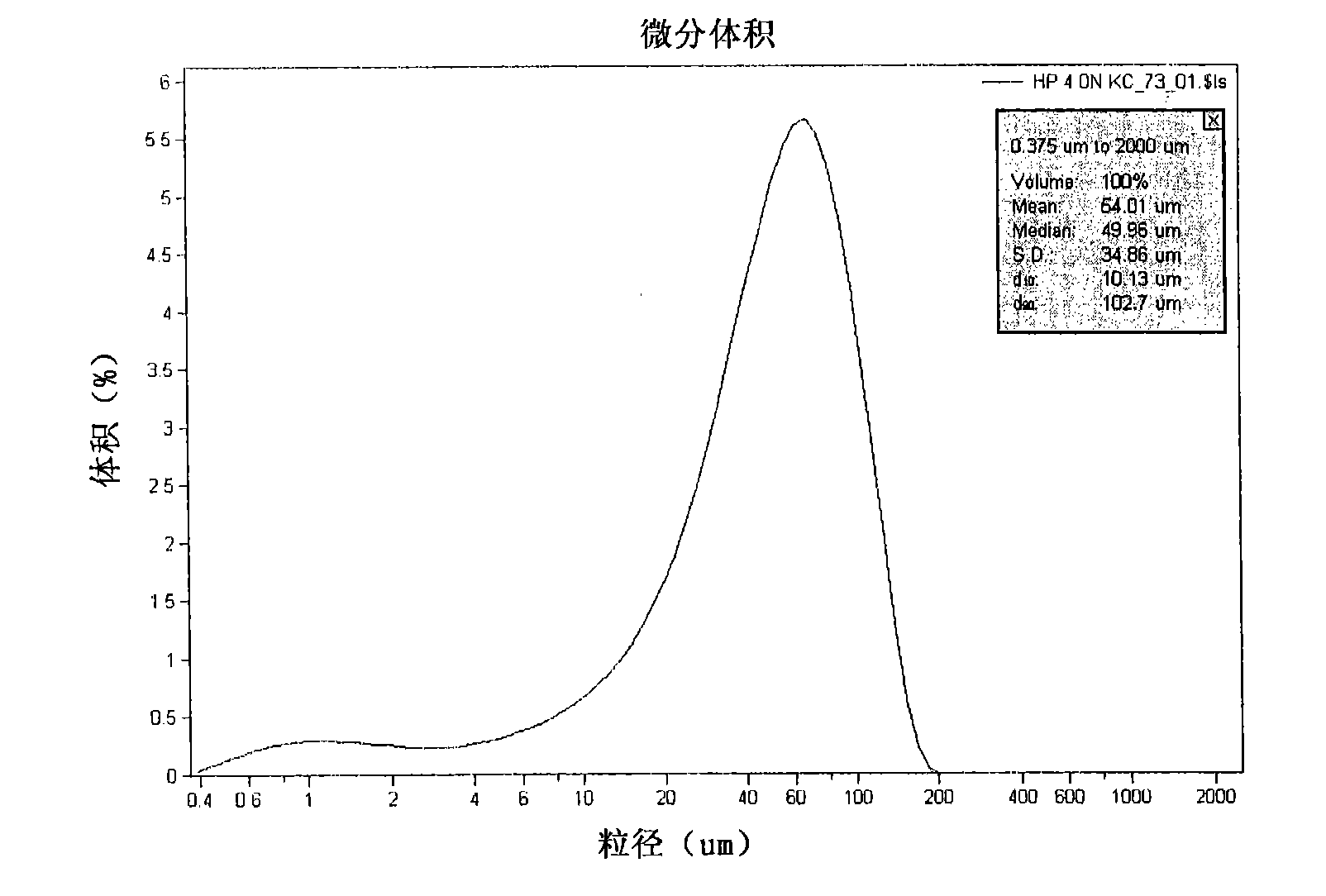

[0054] According to the prescription of table 2-1 (embodiment 1), 2-2 (embodiment 2), 2-3 (embodiment 3) respectively, each component in the table is mixed and prepared to obtain three kinds of paint surface treatment compositions of the present invention . The specific preparation method is: under the condition of low-speed (400-800 rpm) disperser stirring, according to the formula sequence and proportion of each sample in Table 2, the raw materials are sequentially added to the container, first half of the rheological agent is added, and the high-speed (3000-5000 rpm / min) disperse and stir for 10-15 minutes. Then add a rheological agent to adjust the viscosity (12000-20000 centipoise) under the condition of stirring at a medium speed (1200-1400 rpm) to obtain a stable grinding paste system with a pH of 8.2-8.4.

[0055] Table 2-1: Sample 1 Component Formulation

[0056] formula

percentage

supplier

Grinding Dispersion Emulsion

50.65

Table ...

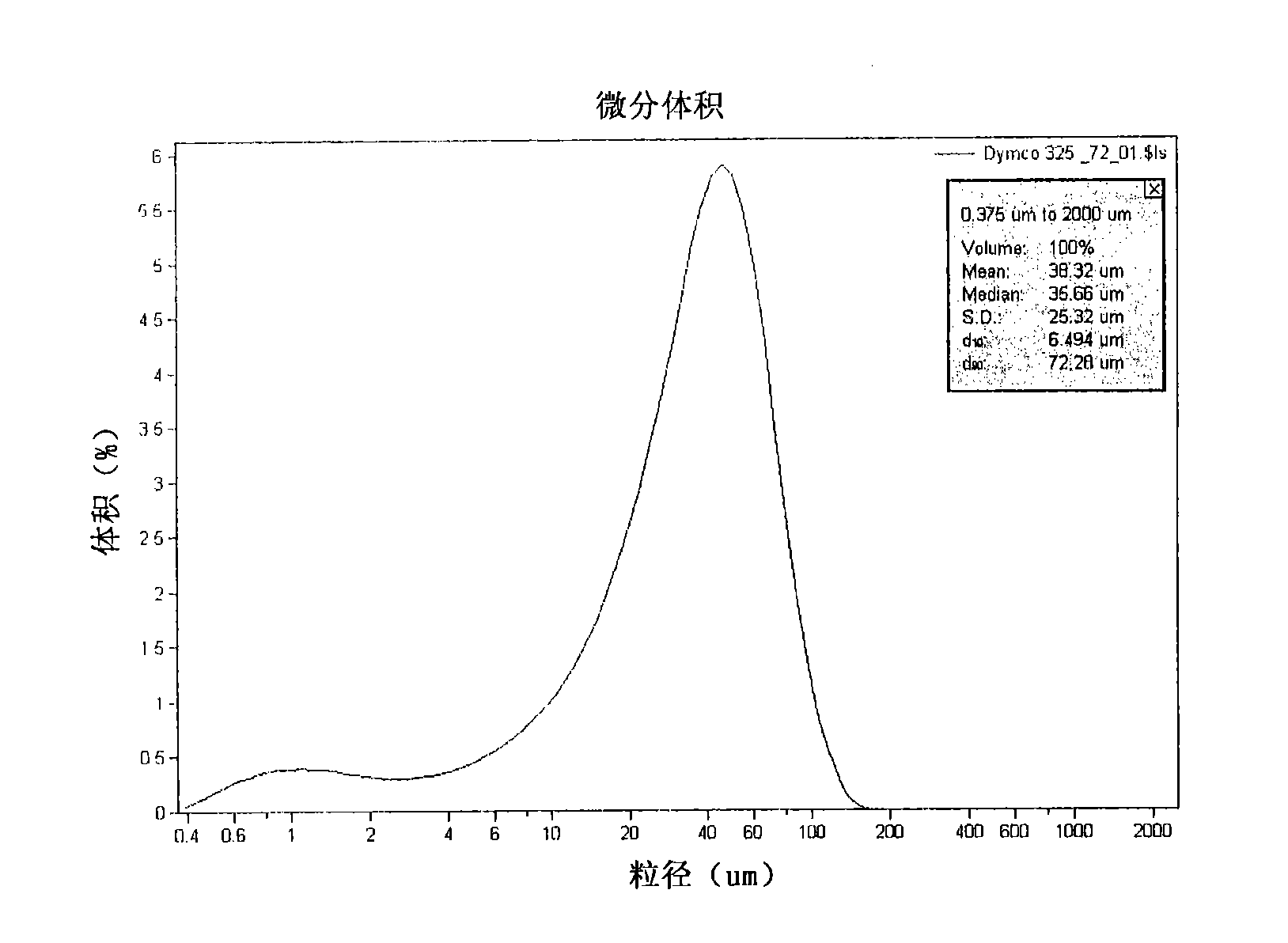

Embodiment 4-6

[0069] According to the same method in embodiment 3, according to the formula preparation paint surface treatment of the present invention respectively according to following table 5-1 (embodiment 4), table 5-2 (embodiment 5) and table 5-3 (embodiment 6) combination.

[0070] Table 5-1: Sample 3 Component Formulation

[0071] formula

percentage

supplier

Grinding Dispersion Emulsion

50.65

Table 1

Hollander's volcanic ash Dymco-325

49

Shanghai Dimengke Company

Rheological agent TT-615

0.35

Rohm & Haas Company

[0072] Table 5-2: Sample 3-2 Component Formulation

[0073] formula

percentage

supplier

Grinding Dispersion Emulsion

64.60

Table 1

Hollander's volcanic ash Dymco-325

35

Shanghai Dimengke Company

Rheological agent TT-615

0.40

Rohm & Haas Company

[0074] Table 5-3: Sample 3-3 Component Formulation

[0075] formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com