Method for manufacturing mechanical drive chain wheel

A production method and mechanical transmission technology, applied in the direction of mechanical equipment, belts/chains/gears, components with teeth, etc., to achieve the effects of overcoming waste of raw materials, stabilizing production processes, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

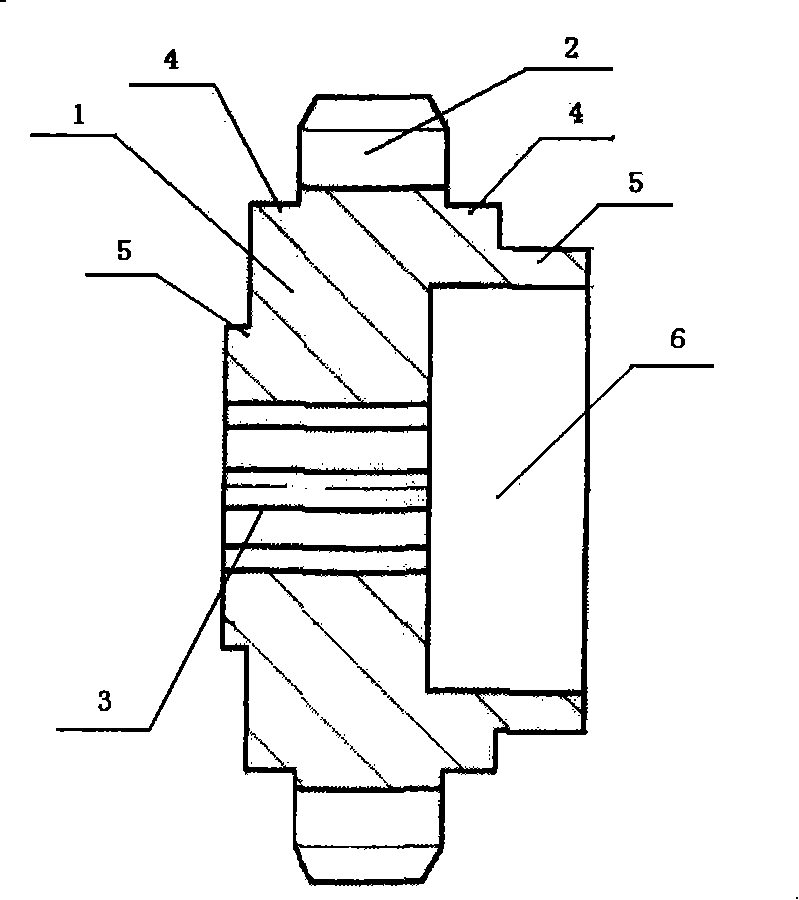

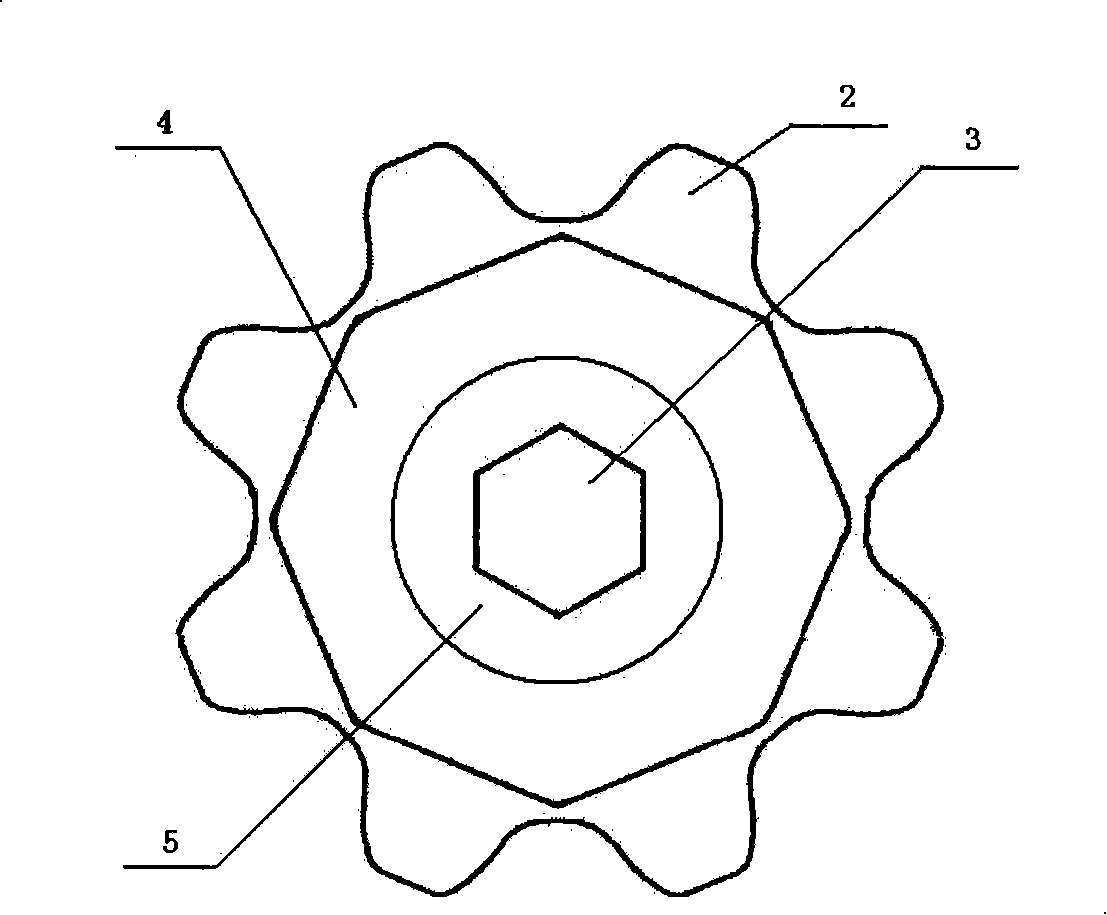

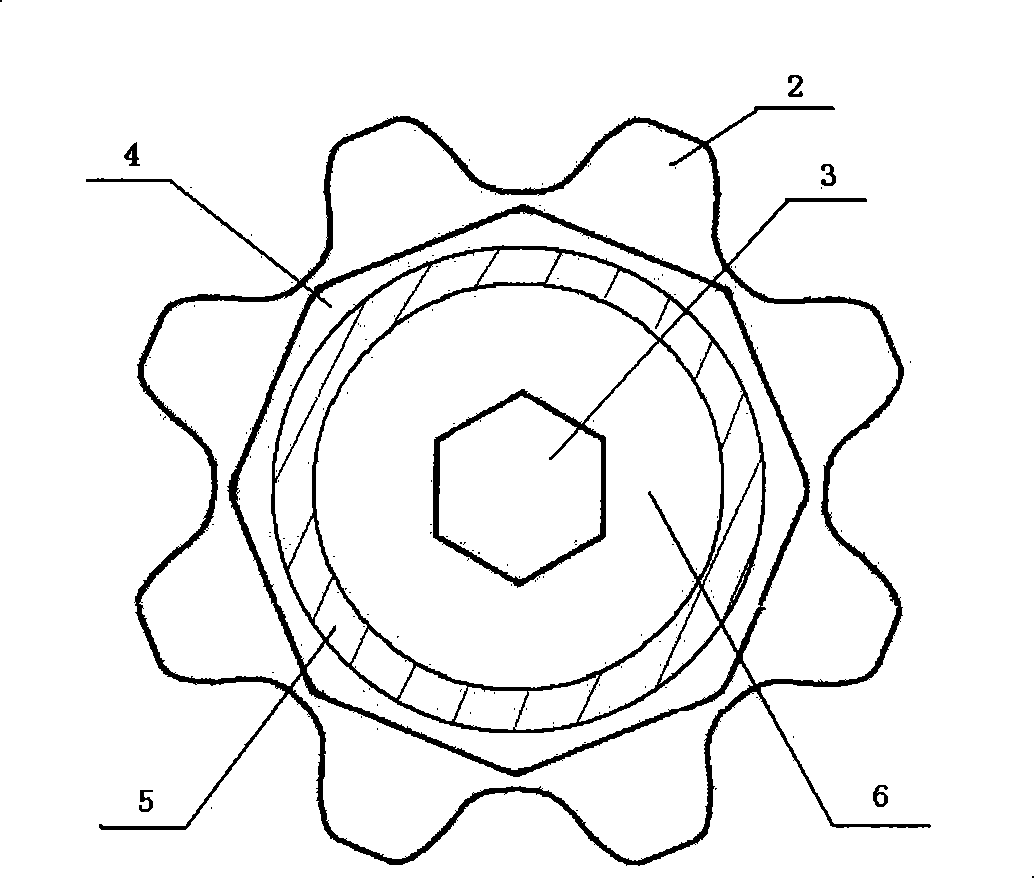

[0027] figure 1 , figure 2 and image 3 Shown is an embodiment of a mechanical transmission sprocket produced by the present invention. A mechanical transmission sprocket, comprising a central part 1 and gear teeth 2, the center of the central part 1 is provided with a shaft hole 3, and the two sides of the central part 1 are respectively provided with octagonal steps 4 and cylindrical The step 5, the octagonal step 4 on one side of the central part 1 and the cylindrical step 5 are hollow steps, the inner cavity 6 of the hollow step is a cylindrical structure, and the shaft hole 3 set in the center of the central part 1 It is a hexagonal shaft hole. The production method of the mechanical transmission sprocket includes blanking, peeling and making billets to remove scale, graphite coating to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com