Winding device and winding method

A winding device and wire material technology, which is applied in electromechanical devices, coil manufacturing, and motor generator manufacturing, etc. It can solve the problems that the motor cannot follow the rotation speed of the head support shaft, and cannot stabilize the winding of the stator magnetic pole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

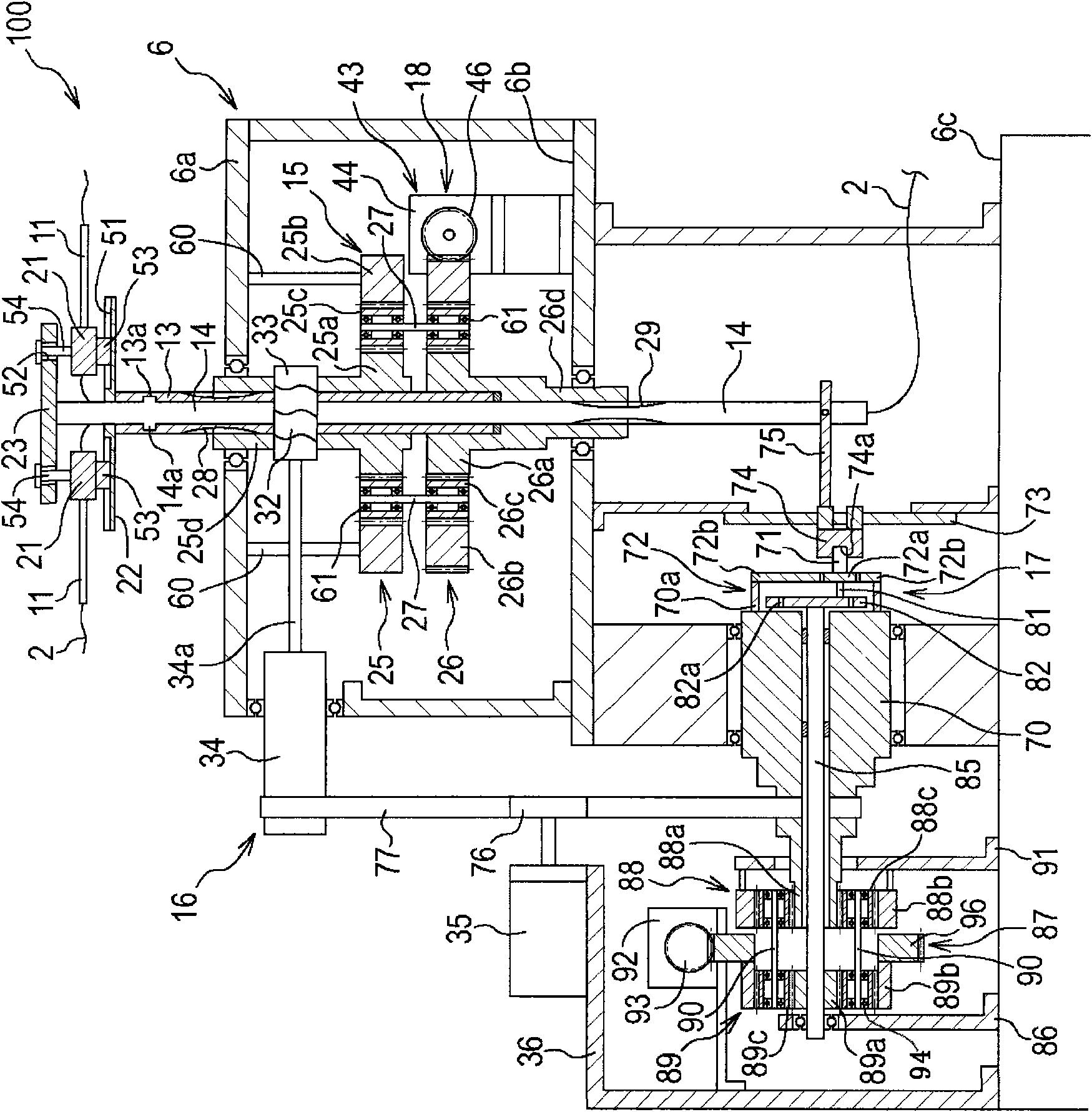

[0014] refer to Figure 1 ~ Figure 3 , the winding device 100 according to the embodiment of the present invention will be described.

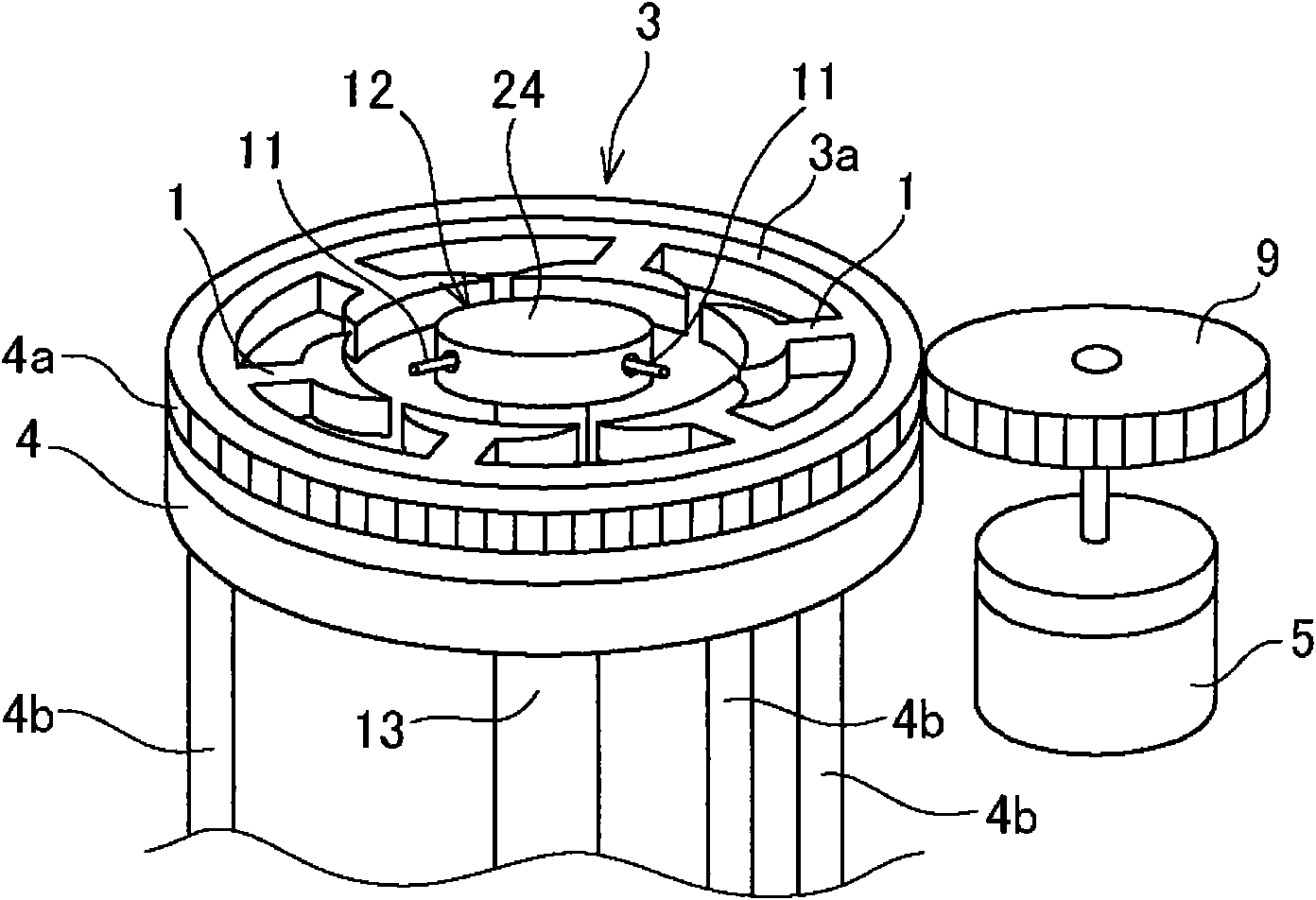

[0015] The winding device 100 is a device for automatically winding the wire 2 on the magnetic pole 1 . In this embodiment, an apparatus for winding the wire 2 around the magnetic poles 1 of the stator 3 in the inner rotor type motor will be described.

[0016] Such as figure 1 As shown, the stator 3 is supported by the stator supporting platform 4, and the indexing motor 5 drives the stator supporting platform 4 to rotate. The stator supporting platform 4 is arranged on the upper layer 6a of the bracket 6 through the support 4b (refer to figure 2 ), the indexing motor 5 is also arranged on the upper layer 6a. And, in figure 2 as well as image 3 In FIG. 2 , illustration of the stator 3 , the stator supporting base 4 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com