Dry etching method for removing silicon nitride film

A technology of silicon nitride thin film and dry etching, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the electrical performance of semiconductor devices, damage, and the inability to deposit gate oxide layers, etc., to achieve reduction The chance of bombardment, reducing the severity, and reducing the effect of potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

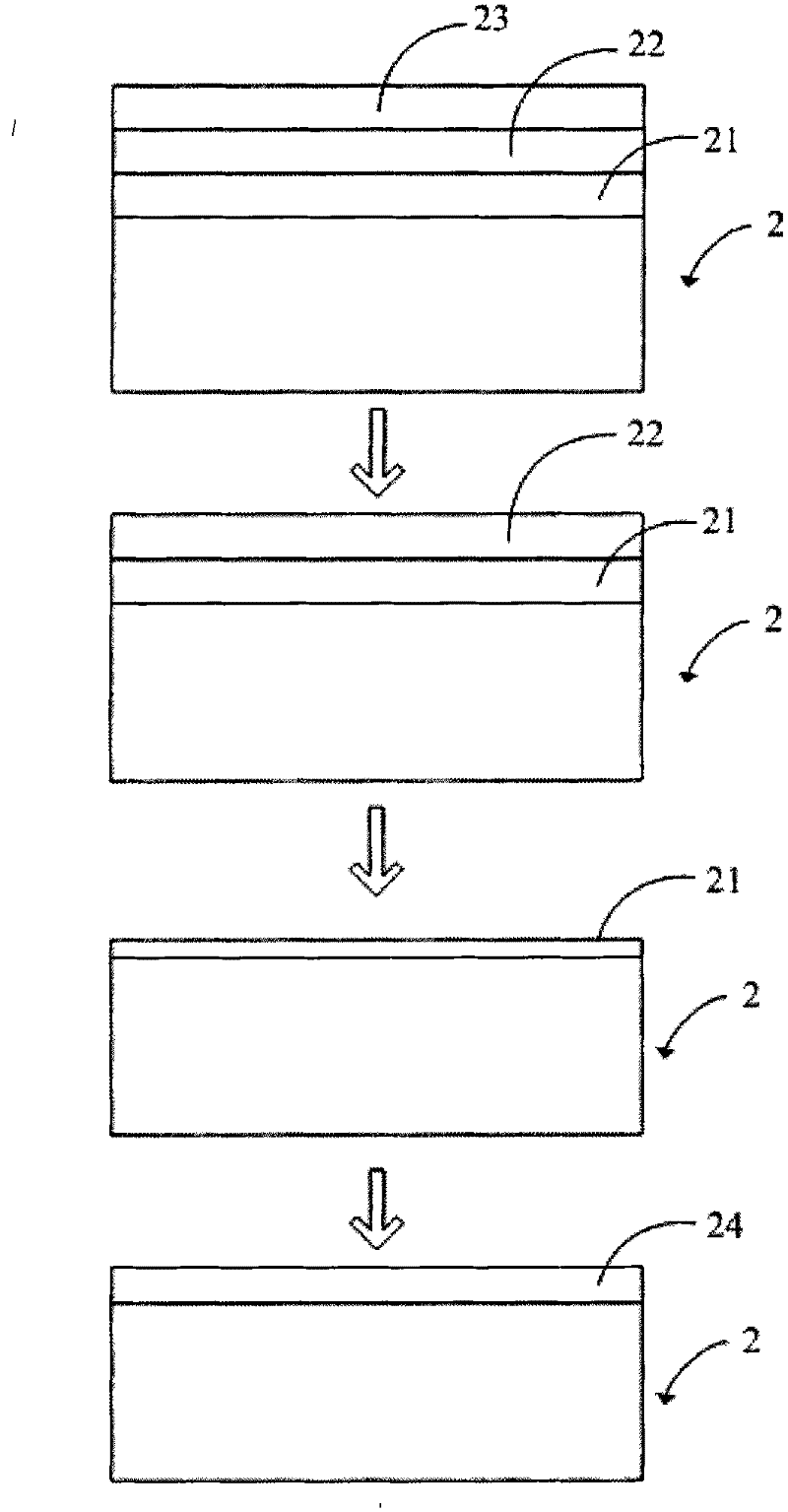

[0010] One embodiment of the dry etching method for removing silicon nitride film provided by the present invention will be described in detail below with reference to the accompanying drawings, in order to further understand the technical scheme, purpose and beneficial effects of the invention. . see figure 2 For the sake of concise description, in this embodiment, the etching of the silicon nitride film, the oxide film where the gate oxide and the inter-electrode oxide are located is referred to as the ONO etching process.

[0011] The dry etching method provided by the invention is applied in the ONO etching process. The dry etching method is used to remove the silicon nitride film 22 in the non-flash MOS tube region, and is performed in a process chamber. The upper and lower sides of the plasma region of the processing chamber have an upper substrate and a lower substrate. The upper plate is connected to the source power to excite the gas input into the process chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com