Sealing gas sampling apparatus

A gas sampling and gas container technology, which is applied in the field of sealed gas sampling realization devices, can solve the problems of sulfur hexafluoride gas loss, serious environmental damage and high price of sulfur hexafluoride gas, avoiding economic losses and being beneficial to the environment. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

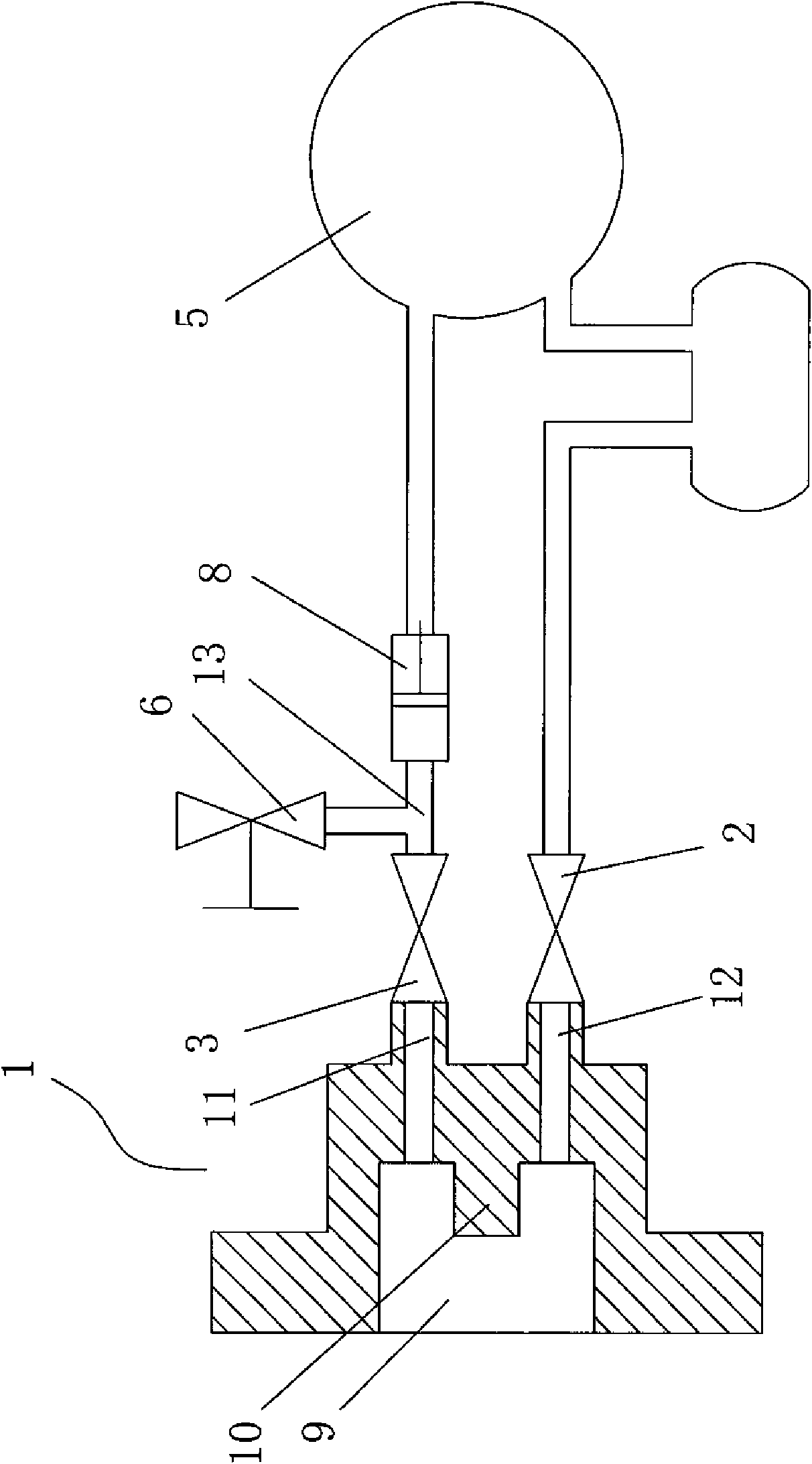

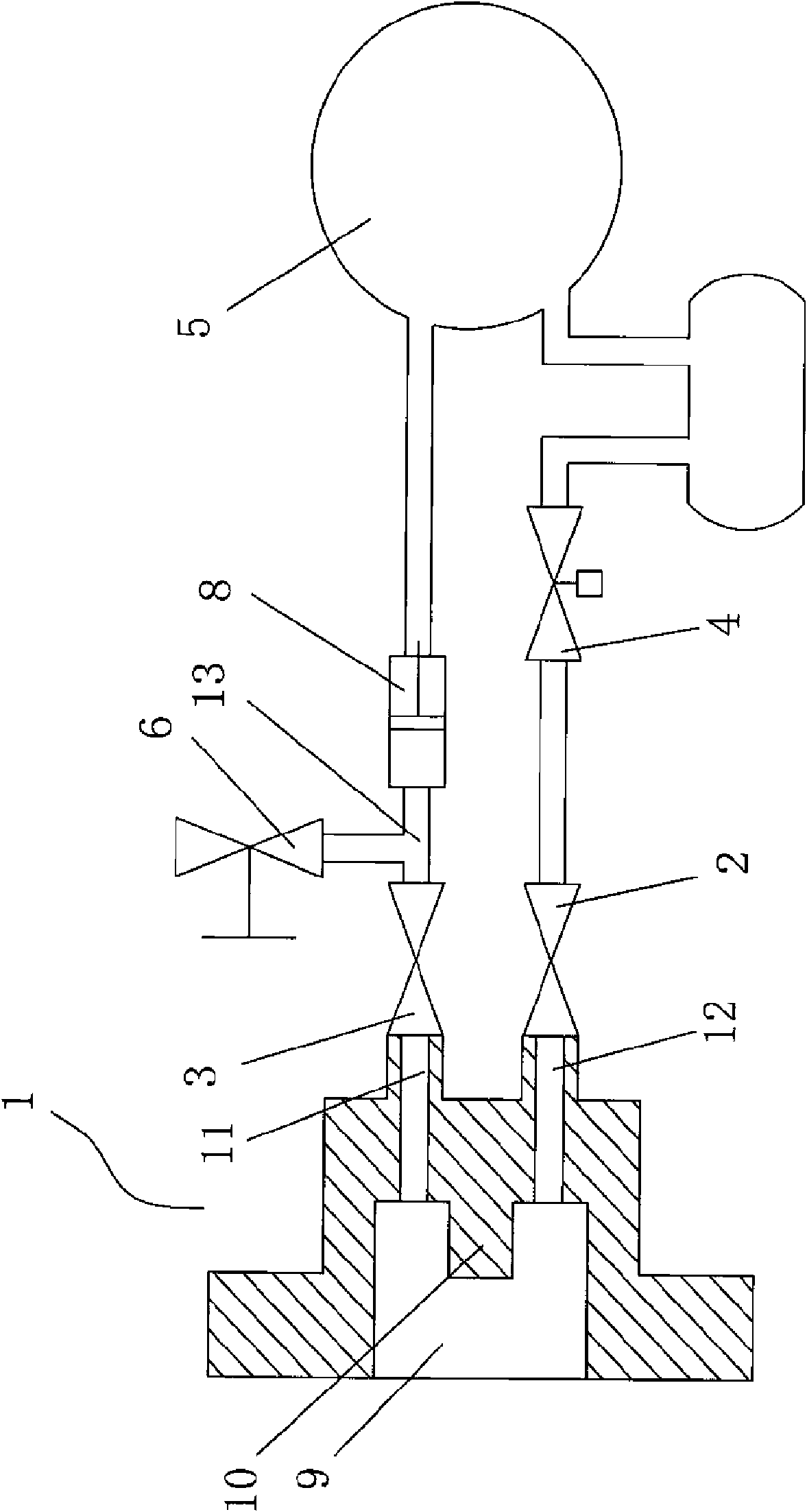

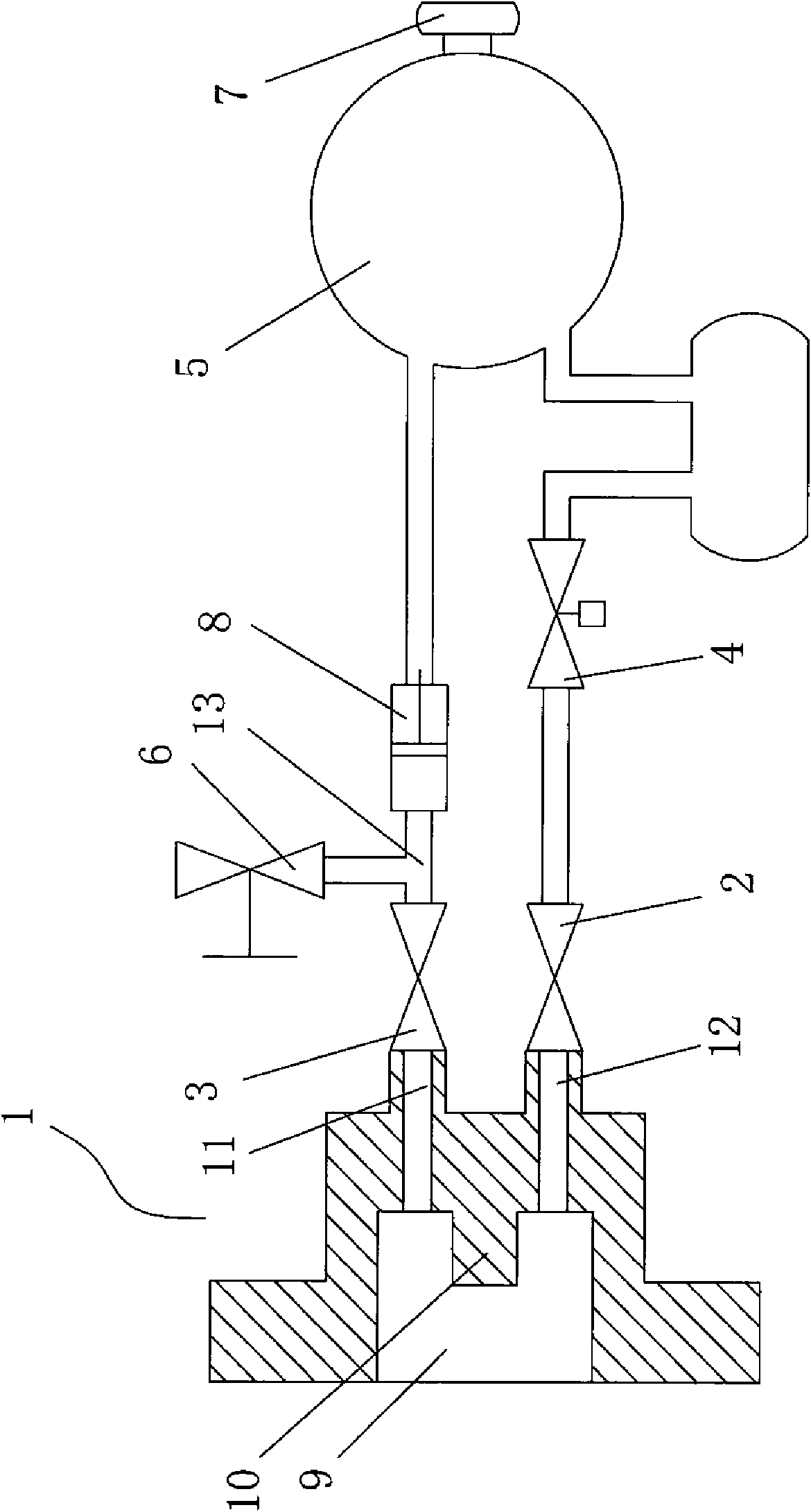

[0025] For the convenience of further understanding the purpose means of the present invention, hereby attach preferred embodiment figure to describe in detail as follows:

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the sealing gas sampling implementation device of the present invention is characterized in that it includes: an adapter 1, a first solenoid valve 2, a second solenoid valve 3, a gas container 5, an exhaust valve 6 and a miniature high-pressure air pump 8;

[0027] Adapter 1 has a one-way check valve connection hole 9 and a boss 10 located in the one-way check valve connection hole at one end, and has an air inlet connected to the one-way check valve connection hole 9 at the other end 11 and the gas outlet 12, the gas outlet 12 of the adapter is connected with the inlet of the first electromagnetic valve 2, the outlet of the gas container 5 is connected with the inlet of the miniature high-pressure air pump 8, and the outlet of the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com