Overload protecting structure of mud pump

An overload protection and sludge technology, applied in the direction of pump, pump control, non-variable-capacity pump, etc., can solve the problems of large loss, burning of the drive motor, complicated dirt, etc., and achieve the effect of reducing the probability of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

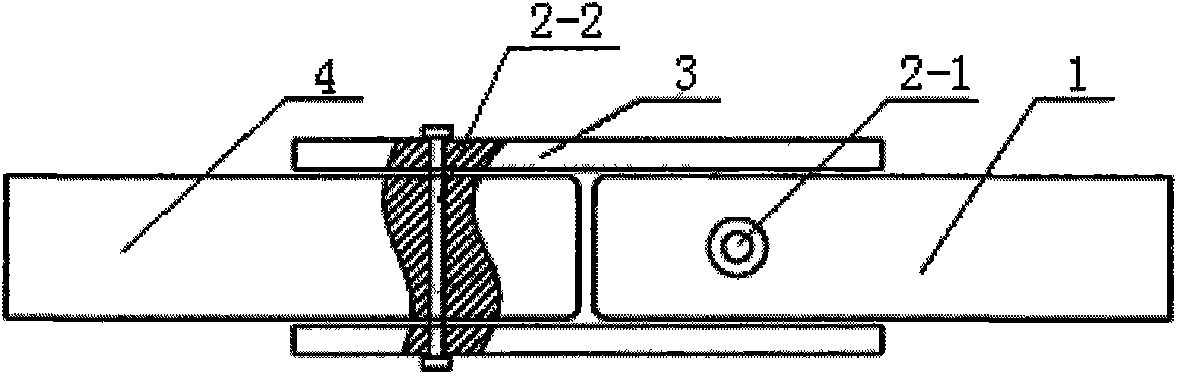

[0012] refer to figure 1 In this embodiment, the driving motor rotating shaft 1 and the sludge pump rotating shaft 4 are connected through a torque transmission sleeve 3, and there is a gap between the end of the driving motor rotating shaft 1 in the sleeve and the end of the sludge pump rotating shaft 4, and the driving motor The rotating shaft 1 is fixed on the sleeve wall through the overload protection pin I 2-1, the sludge pump rotating shaft 4 is fixed on the sleeve wall through the overload protection pin II 2-2, and the overload protection pin I 2 of the drive motor rotating shaft 1 is fixed -1 and the overload protection pin II 2-2 of the fixed sludge pump rotating shaft 4 are orthogonally distributed.

[0013] The maximum shear force that the overload protection pin I 2-1 and the overload protection pin II 2-2 can withstand is set in advance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com