Water-wheel type pulse pump and water turbine generator for same

A technology of turbo generator and pulse pump, which is applied in the direction of hydroelectric power generation, impact engine, engine components, etc., can solve disadvantages and other problems, and achieve the effects of easy maintenance, saving capital investment, and improving air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

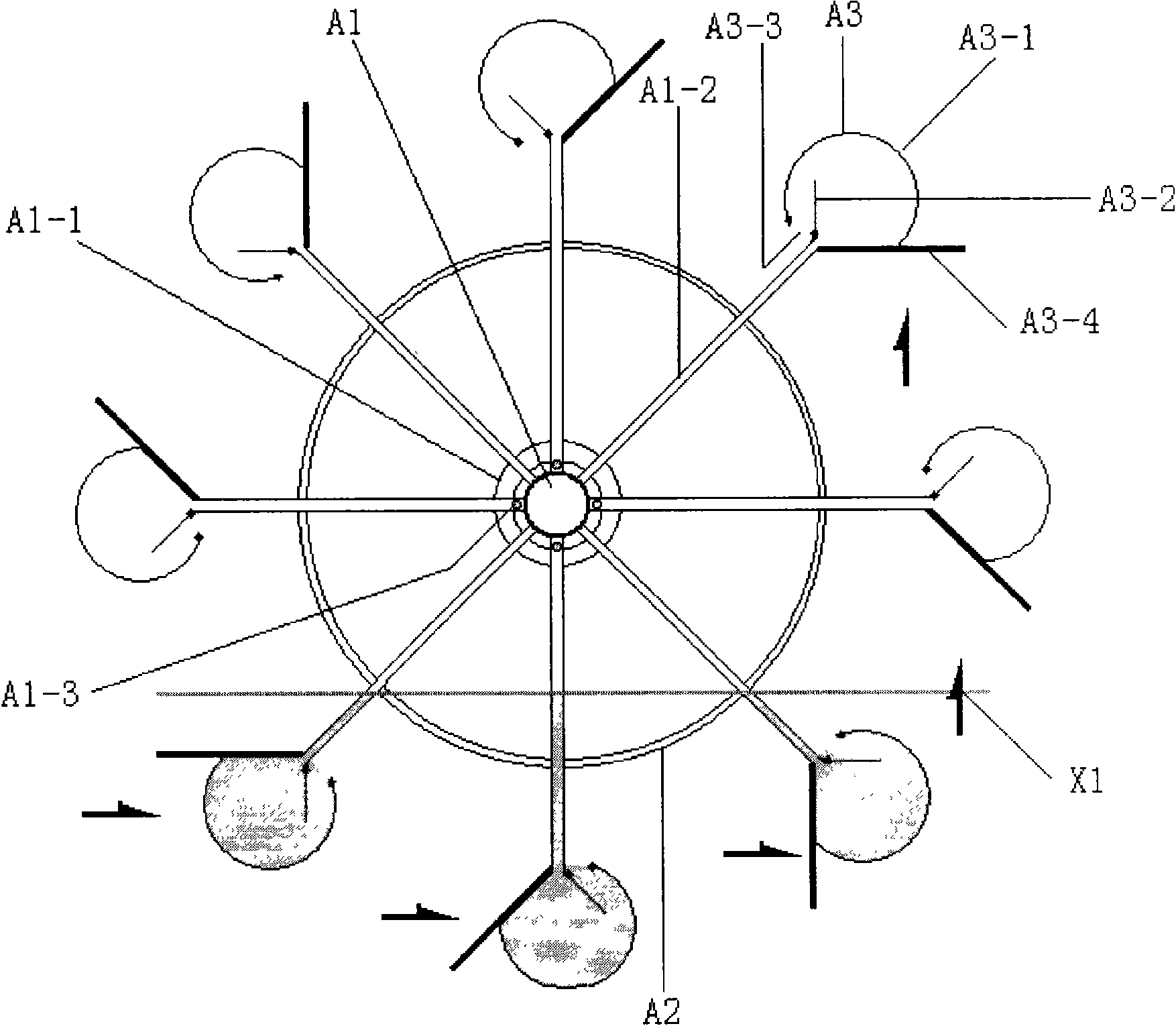

[0039] exist Figure 1 Middle: Side view of the water wheel of the ball valve water wheel pulse pump

[0040] In the figure: (A1) main output pipe of pump water, (A1-1) water valve lumen, (A1-2) pump water pipe, (A1-3) ball valve, (A3) water inlet scoop, (A3-1) water Scoop, (A3-2) water retaining tongue plate, (A3-3) water inlet, (A00) guard net cover, (A3-4) water flow push plate.

[0041] In the figure: the (A1-1) water valve lumen is connected outside the (A1) pump water main output pipe; the (A1-2) pump water pipe is connected outside the (A1-1) water valve lumen; -2) The connection between the pump water pipe and the (A1-1) water valve lumen is connected to the (A1-3) ball valve; the lower end of the (A1-2) pump water pipe is connected to the (A2) fixed ring; in (A1-2) The front end of the pump pipe is connected to the (A3) water inlet scoop; the (A3-1) water scoop is connected to the (A3-2) water retaining flap and the (A3-3) water inlet, and on the (A3-3) water inlet ...

Embodiment 2

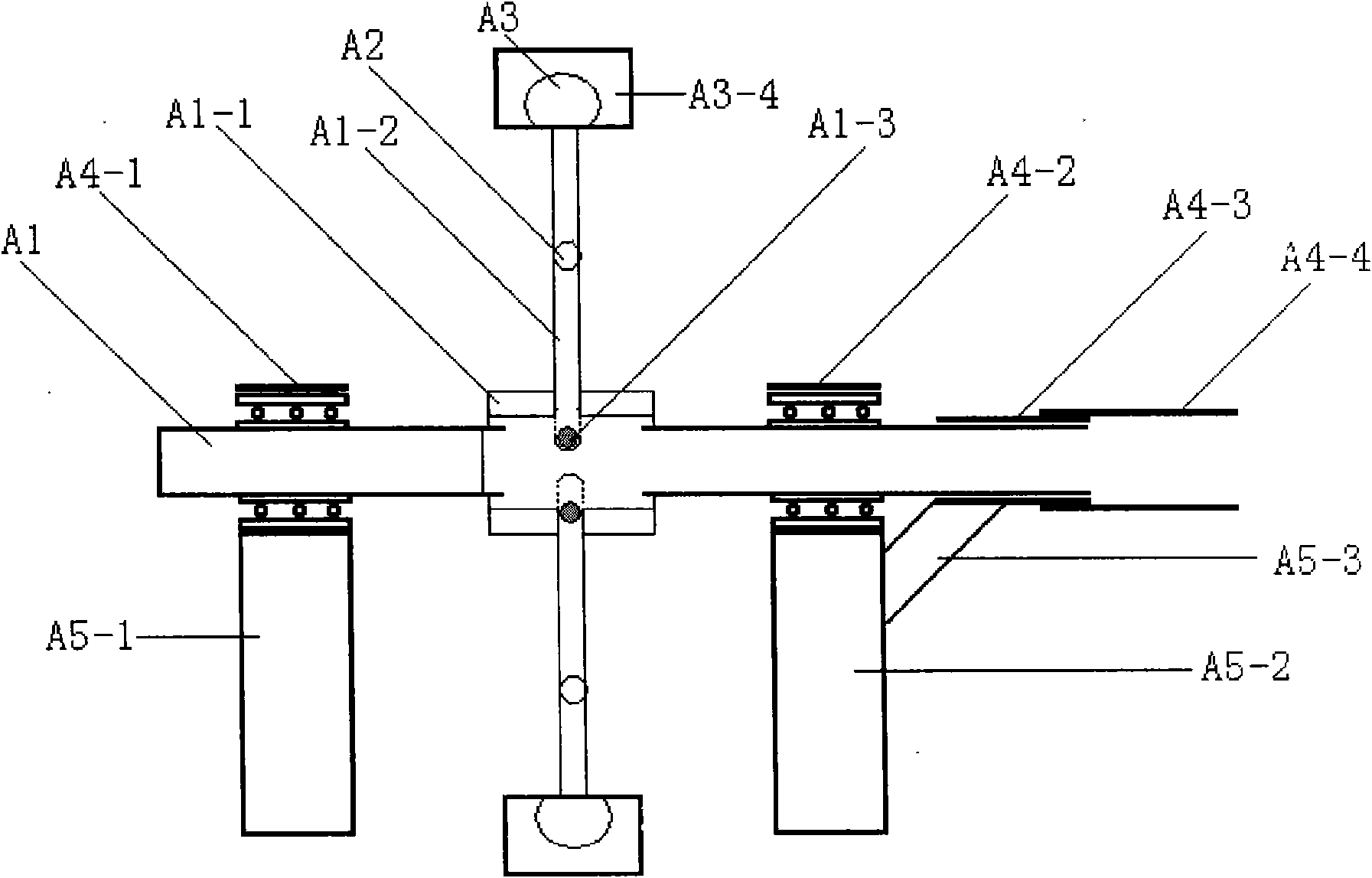

[0058] exist Figure five and Figure six Middle: Sectional diagram of vane valve waterwheel pulse pump

[0059] In the figure: (A1) main output pipe of pump water, (A1-1) water valve lumen, (A1-2) pump water pipe, (K1-1), (K1-2), (K1-3), (K1 -4) Valve vane, (K2-1), (K2-2), (K2-3), (K2-4) vane shaft, (K3-1), (K3-2), (K3-3), (K3-4) angle buckle, (A3) water inlet scoop, (A3-1) water scoop, (A3-2) water retaining tongue, (A3-3) water inlet, (A00) guard net cover, (A3 -4) water flow push plate, (A4-1) front bearing, (A4-2) rear bearing, (A4-3) sealing shaft sleeve, (A4-4) water pipe, (A5-1) front bracket, (A5 -2) Rear bracket, (A5-3) support bracket, (X1) running water, (X2) water surface inside the pump tube, (Z1) water flow direction, (Z2-1) (Z2-2) water ladle rotation direction.

[0060] In the figure: (A1) the pump water main output pipe is connected with the (A1-1) water valve lumen; the (A1-1) water valve lumen is connected with the (A1-2) pump water pipe; in (A1- 2) Th...

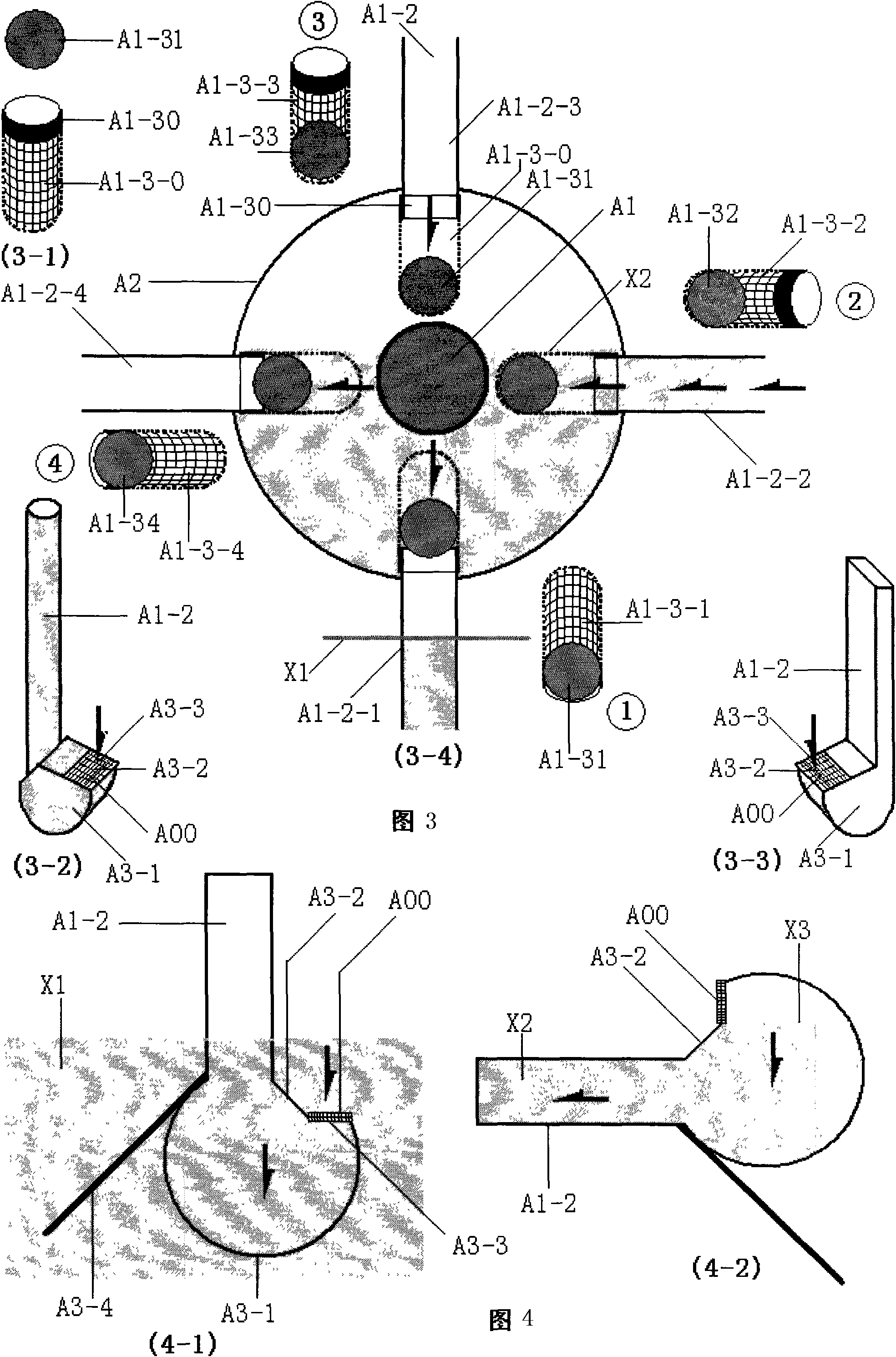

Embodiment 3

[0065] exist Figure 9 Middle: Cross-section diagram of water turbine generator

[0066] In the figure: (W) water turbine, (W1) turbine, (W2) turbine shaft, (W3) turbine upper bearing, (W4) gear, (W5) turbine lower bearing, (W6) transmission gear set, (L) set Water pan, (L1) Vertical side of pan, (L2) Connecting column, (L3) Return water collection pipe, (M1) Generator, (M2) Generator shaft, (M3) Generator shaft gear, (M4) Output source line, (M5) power switch box, (N) frame, (N1) upper connection side frame for generator, (N2) lower connection side frame for water turbine, (N3) base side frame, (N4) wheels.

[0067] In the figure: the (N4) wheel is connected under the (N3) base side frame of the (N) frame; the (M1) generator connected with the (M5) power switch box and the (M4) output source line is connected above; (M1) The (M2) generator shaft connected to the generator is connected to the (M3) generator shaft gear on the side frame connected to the (N1) generator; the (M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com