Holding type major diameter static pressure sinking pipe cast-in-place pile construction method and pile-pressing machine thereof

A technology of immersed tube grouting piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of easy fracture of hard layers, burst piles, and easy corrosion of pile joints, etc., and achieve stable and reliable construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

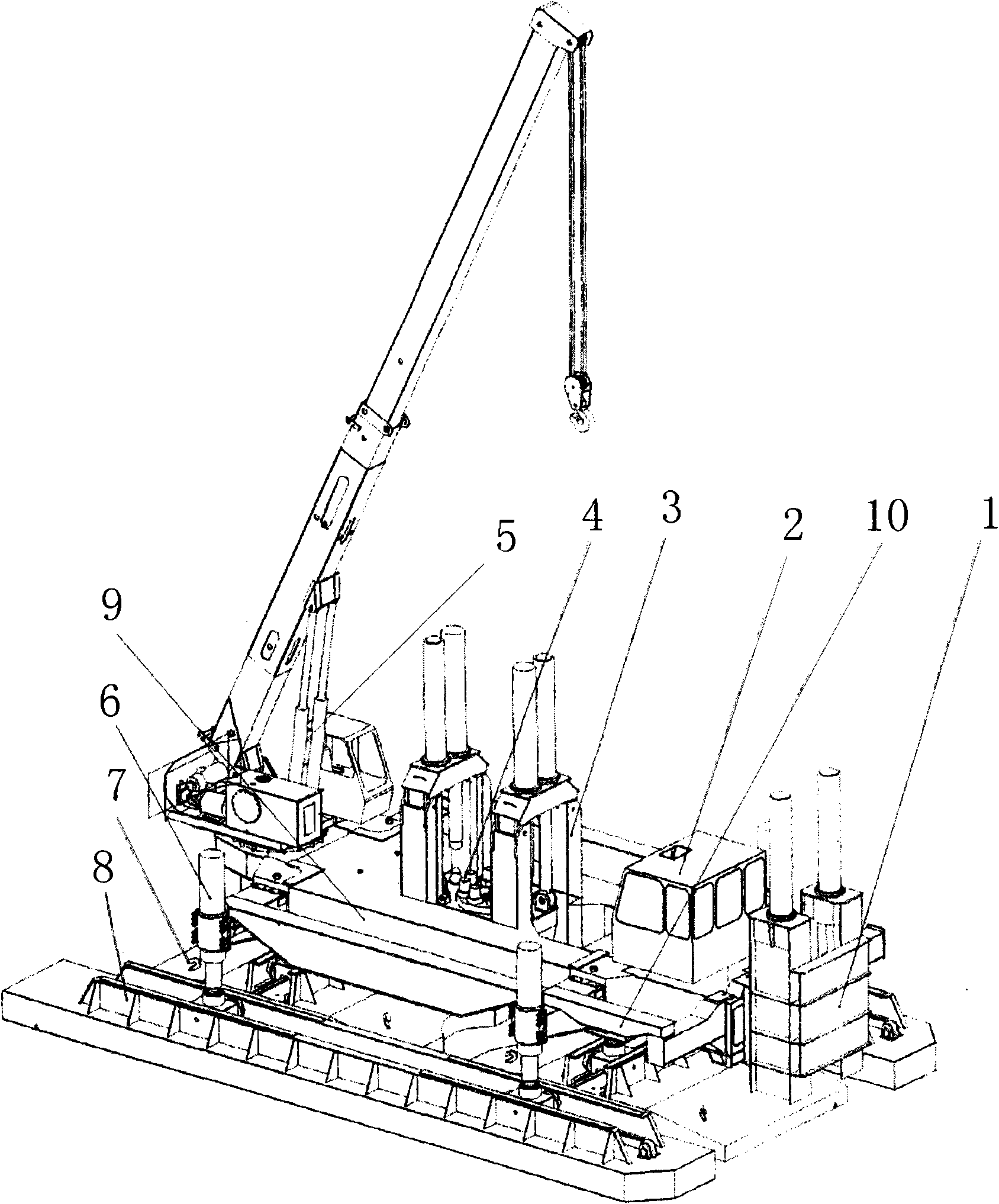

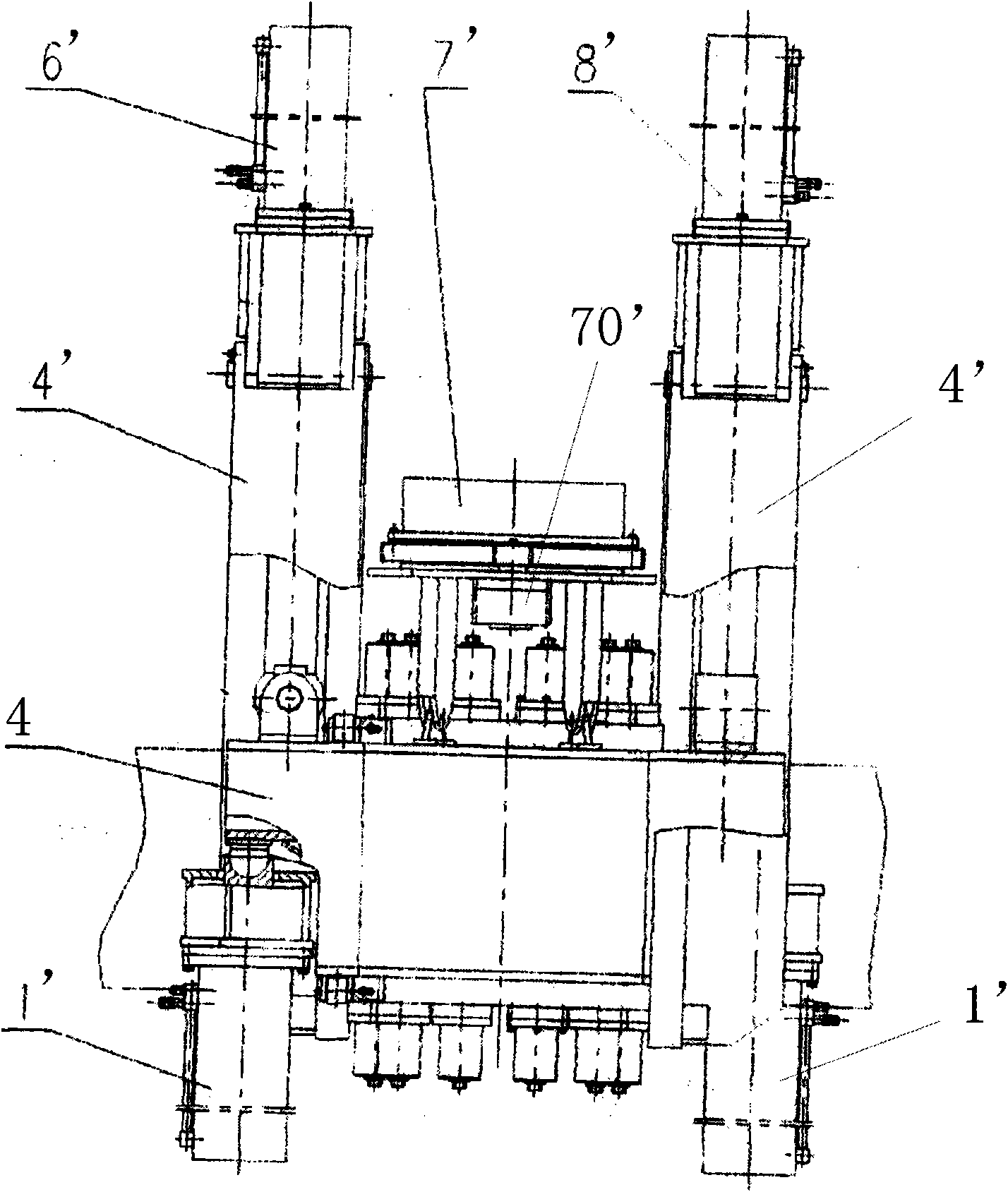

[0034] The pile driver of the embodiment of the present invention is as figure 1 , figure 2 Shown: a body consisting of a walking mechanism, a crane 5, a counterweight structure and a frame. Counterweight beam 10 and counterweight, pile driver also has side pile device 1, structures such as main driver's cab 2. The frame is also equipped with a pile-pressing platform 3, which is composed of a pile-pressing column 4', a main pile-pressing cylinder 6', an auxiliary pile-pressing cylinder 8', a hydraulic gyrator 7', and a pile-clamping box 4. The pile-pressing column 4' is symmetrically fixed on the machine frame relative to the pile-clamping box 4, the main pile-pressing cylinder 6' and the auxiliary pile-pressing cylinder 8' are respectively fixed on the pile-pressing column 4', the main pile-pressing cylinder 6', the auxiliary pile-pressing cylinder The lower end of the cylinder rod of the pile pressing cylinder 8' is connected to the pile clamping box 4, and the middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com