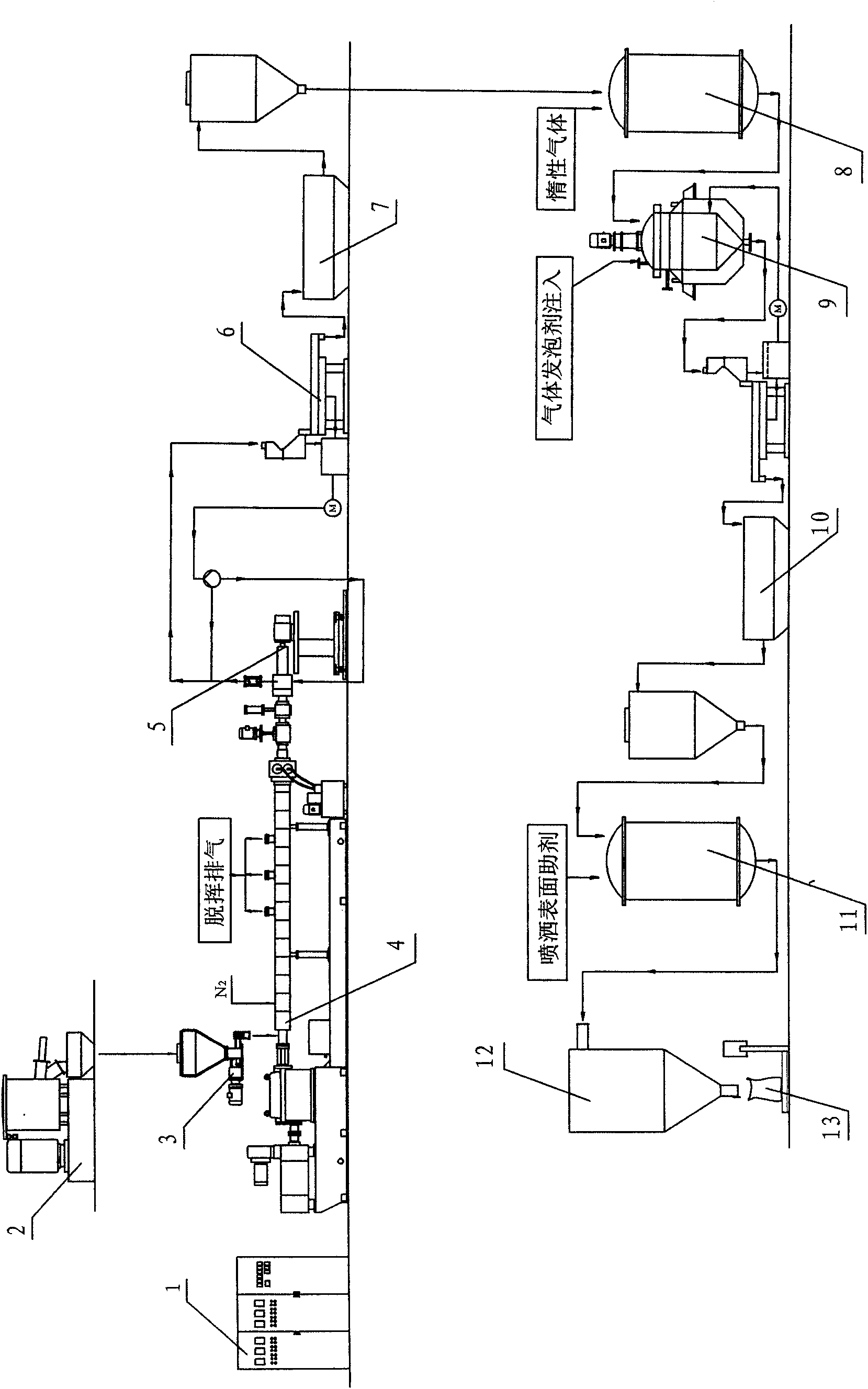

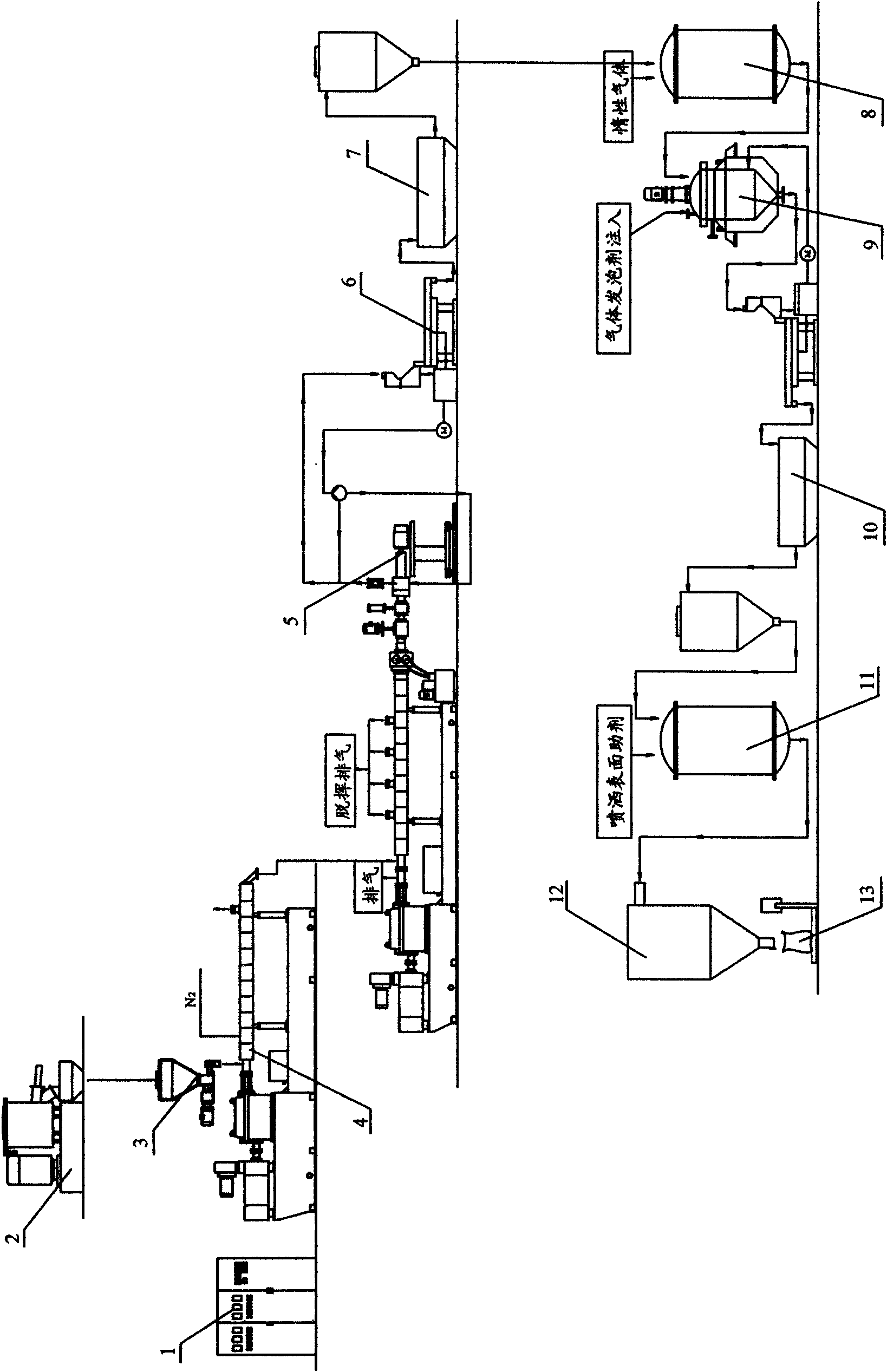

Production line of EPP polypropylene foaming beads

An expanded bead and production line technology, applied in the direction of coating and the like, can solve the problem of not disclosing the content of the EPP polypropylene expanded bead production line, etc., and achieve the effect of stable product quality and uniform content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An EPP polypropylene foamed bead production line of the present invention includes a twin-screw extruder, an underwater pelletizing system, a dehydration system, a drying system, and an electrical control cabinet connected to each equipment, and is characterized in that it also includes low-temperature mixing System, sealed leak-proof feeder, plasma fluidized bed reactor, water-soluble reaction system and surface treatment mixing system, each equipment or system is connected in the following order: low-temperature mixing system → sealed leak-proof feeder → twin-screw Extruder → underwater pelletizing system → first deep drying system → plasma fluidized bed reactor → water-soluble reaction system → second deep drying system → surface treatment mixing system → finished product silo and packaging system, the twin-screw extruder A gas blowing agent injection port is provided on the machine; a plasma reaction device and an inert gas injection device are arranged on the plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com